Industrial 3D Printing & Additive Manufacturing

Transform your product development with advanced additive manufacturing. From aerospace-grade metals to medical polymers, we deliver precision parts that push the boundaries of what's possible.

The Evolution of Manufacturing

Additive manufacturing represents a fundamental paradigm shift from traditional subtractive processes, building parts layer by layer rather than cutting away material.

This revolutionary approach unlocks design possibilities impossible with conventional machining while eliminating tooling requirements, reducing waste, and enabling rapid iteration for both prototyping and production applications.

Beyond traditional manufacturing constraints, additive technologies enable complex internal geometries, lightweight lattice structures, and part consolidation that transforms how engineers approach design. From aerospace components requiring 60% weight reduction to medical devices with patient-specific geometries, this technology delivers both the design freedom and material performance demanded by today's most challenging applications.

With materials ranging from high-performance thermoplastics to aerospace-grade titanium alloys, additive manufacturing has evolved from prototyping tool to full-scale production technology—enabling on-demand manufacturing, supply chain resilience, and sustainable production practices across industries.

Our mission

We're democratizing advanced manufacturing by making industrial-grade 3D printing accessible to innovators across all industries, from aerospace giants to emerging startups.

Our mission extends beyond simply providing manufacturing services—we're partnering with engineers and designers to push the boundaries of what's possible in product development. Through cutting-edge additive technologies, comprehensive material portfolios, and expert engineering support, we transform complex design challenges into production realities.

- Manufacturing technologies

- 6

- Material options available

- 25+

- Industries served

- 8+

Additive vs Traditional Manufacturing

Understanding the fundamental differences between additive manufacturing and conventional subtractive processes helps identify the optimal approach for your application requirements.

| Aspect | Additive Manufacturing | Traditional Machining |

|---|---|---|

| Design Freedom | Complex internal geometries, lattice structures, topology optimization | Limited by tool access, requires assembly for complex forms |

| Lead Times | 24-48 hours from CAD to part | Weeks for tooling design and manufacturing |

| Material Waste | Near-zero waste, unused powder recyclable | Significant material removal and waste |

| Customization | Each part can be unique at no extra cost | Tooling changes required for variations |

Both technologies excel in different scenarios. Our engineering team can help determine the optimal approach for your specific requirements.

Industry Applications

3D printing technology serves diverse industries with unique requirements, from aerospace precision to medical biocompatibility and architectural visualization.

Advanced Manufacturing Technologies

Six specialized additive manufacturing technologies, each optimized for specific material types and application requirements, from high-volume production thermoplastics to precision aerospace metallurgy.

Selective Laser Sintering

Support-free manufacturing of complex geometries using engineering-grade nylon materials. High mechanical strength with ...

Multi-Jet Fusion

Precision engineering with fine detail resolution and excellent surface quality. Production-grade materials for strength...

Fused Deposition Modeling

Industry-leading precision with best-in-class repeatability and layer adhesion using industrial-grade thermoplastics....

Fused Filament Fabrication

Accessible extrusion-based 3D printing for rapid concept validation, design iteration, and non-critical prototyping with...

Stereolithography

Ultra-high resolution resin parts with smooth surface finish and exceptional detail....

Direct Metal Laser Sintering

Fully dense, high-performance metal parts with exceptional strength for aerospace, automotive, and medical applications....

Selective Laser Melting

Complete powder melting for ultra-high density metal parts with superior mechanical properties and fine surface detail....

PolyJet Matrix

Multi-material 3D printing with exceptional detail resolution and the ability to combine rigid, flexible, and transparen...

CNC Machining

Precision subtractive manufacturing for high-tolerance parts across metals and advanced engineering polymers. Multi-axis...

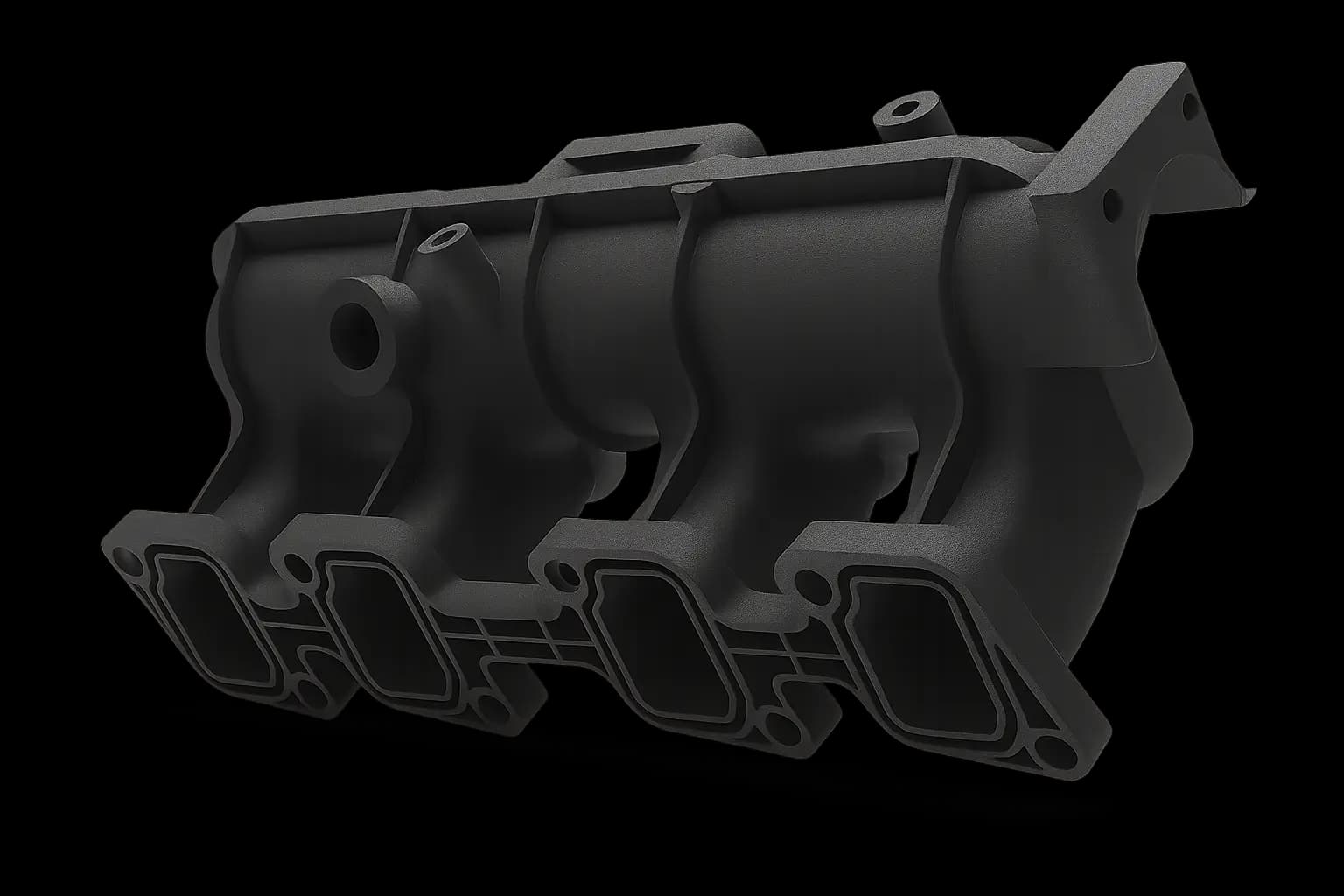

Precision Manufacturing Examples

From complex assemblies to intricate geometries, our advanced manufacturing capabilities deliver exceptional quality across diverse applications and industries.

Topology Optimization

DMLS Titanium Ti-64

Automotive Assembly

SLS PA12 Nylon

Dashboard Prototype

SLA Accura 25

Critical Industry Applications

From aerospace to medical devices, our advanced manufacturing capabilities enable mission-critical components across industries where precision, reliability, and regulatory compliance are paramount.

Certified Materials Portfolio

Comprehensive library of certified engineering materials, from production-grade thermoplastics to aerospace metallurgy, with complete material traceability and regulatory documentation for mission-critical applications.

Precision Engineering & Quality Assurance

Every manufactured component meets stringent quality standards for dimensional accuracy, material properties, and surface finish, supported by comprehensive quality control protocols and regulatory certification.

ISO 9001:2015 Quality System

Comprehensive quality management system built to ISO 9001:2015 standards ensuring consistent manufacturing processes and continuous improvement across all production operations.

±0.1mm Dimensional Precision

Advanced process monitoring and post-production inspection protocols ensure dimensional accuracy and repeatability across all manufacturing runs.

Complete Material Traceability

Full documentation chain from raw material certification through final inspection, ensuring regulatory compliance for mission-critical applications.

Advanced Manufacturing Solutions

Whether developing next-generation prototypes or scaling production operations, our advanced additive manufacturing technologies deliver the precision and reliability required for mission-critical applications.