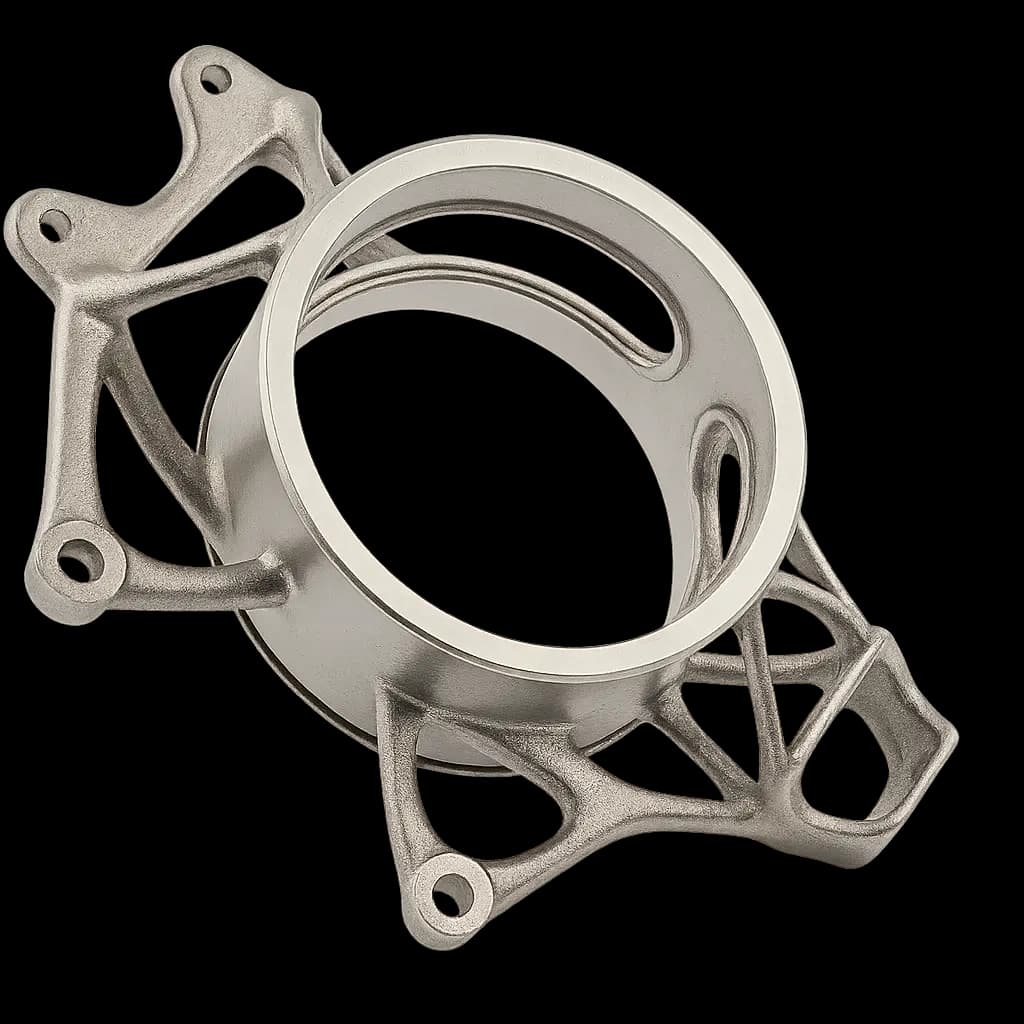

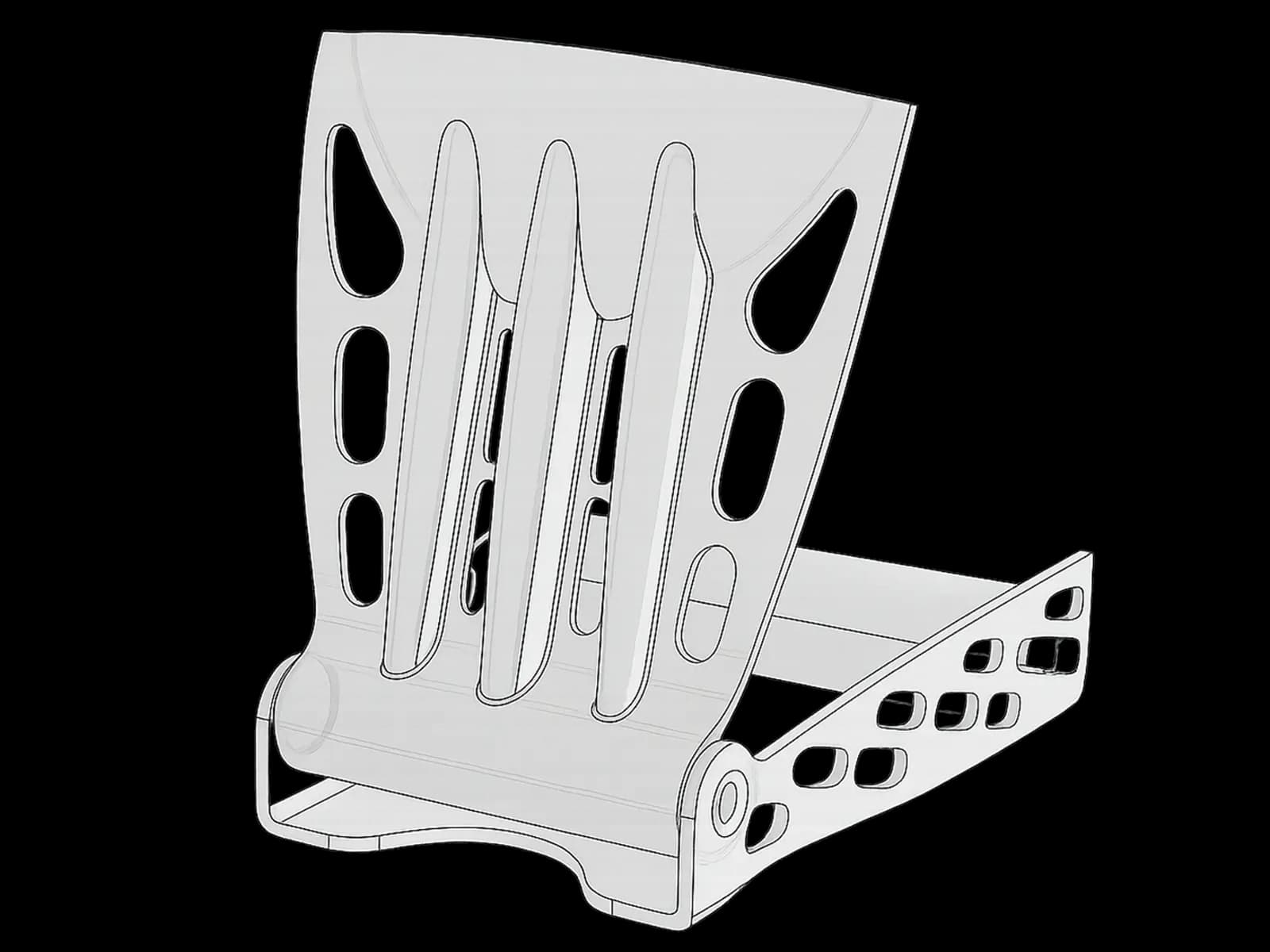

Titanium Ti-6Al-4V

Aerospace-Grade Lightweight Alloy

Titanium Ti-6Al-4V (Grade 5) is the most widely used titanium alloy in aerospace and automotive applications. This alpha-beta alloy offers an exceptional strength-to-weight ratio and excellent corrosion resistance.

Tensile Strength

1080 MPa

Elastic Modulus

114 GPa

Temp Resistance

350 °C

Compliance

ASTM F1472/ASTM F2924/ASTM F3302

Applications

Aerospace Structures/Precision Components/Automotive Racing/Sports Equipment