PA12 ESD prevents costly damage during PCB assembly and semiconductor handling. The material's consistent conductivity ensures reliable protection across complex geometries.

Key Applications

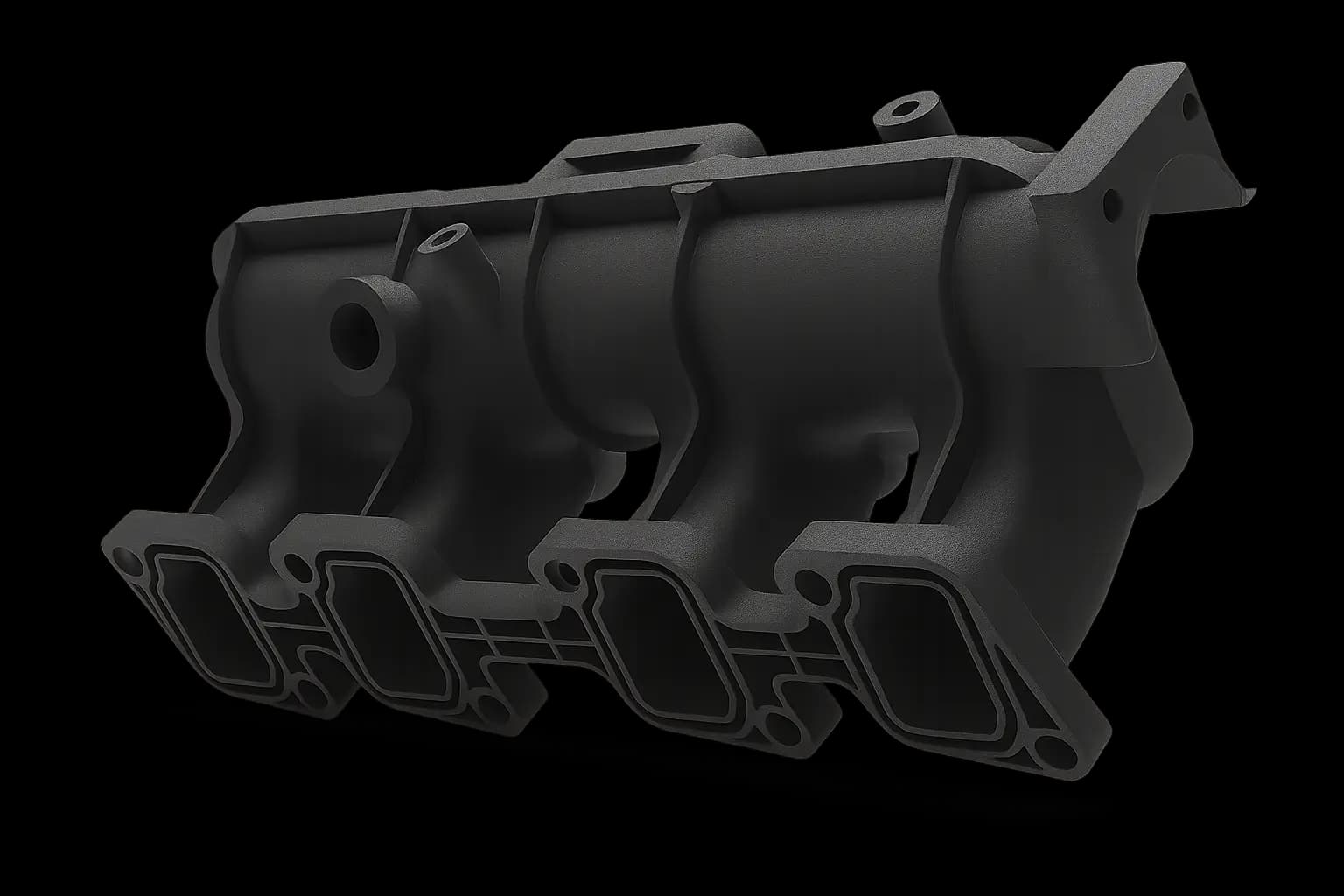

- PCB assembly fixtures and carriers

- IC shipping trays and tubes

- Test socket assemblies

- Component handling tools

Performance Data

Surface resistance 10^7-10^8 ohms per IPC-A-610, dissipating 5kV charge in <2 seconds for ANSI/ESD S20.20 compliance.