Engineering the Future of Energywith Advanced Manufacturing

Additive Manufacturing for Clean Tech, Energy, and Power Systems. We support energy innovators with fast-turn, precision 3D printed parts—from hydrogen fuel cell housings and battery enclosures to lightweight mounting systems and rapid tooling. Forge Labs clean tech 3D printing delivers durable components for renewable energy and electrification programs.

Energy & Clean Tech Excellence

Manufacturing for Energy Innovation

Whether you're advancing next-gen hydrogen technology, EV power systems, or solar infrastructure, Forge Labs helps energy manufacturers bring products to life faster. Our industrial 3D printing technologies are ideal for functional prototypes, thermal housings, and test fixtures—built to withstand demanding environments. We've partnered with leading North American energy companies to deliver mission-critical parts for testing, validation, and production support.

Transforming Energy & Clean Tech Manufacturing

Whether you're advancing next-gen hydrogen technology, EV power systems, or solar infrastructure, Forge Labs helps energy manufacturers bring products to life faster. Our industrial 3D printing technologies are ideal for functional prototypes, thermal housings, and test fixtures—built to withstand demanding environments. We've partnered with leading North American energy companies to deliver mission-critical parts for testing, validation, and production support.

Key Benefits of 3D Printing in Energy & Clean Tech

- Accelerate development timelines and compress design cycles, enabling faster innovation and reduced time-to-market.

- Create complex thermal management systems impossible with traditional manufacturing through advanced additive manufacturing solutions tailored for energy & clean tech applications.

- Eliminate expensive tooling requirements, reducing upfront investments and enabling economical low-volume production.

- Enable lightweight designs for improved energy efficiency through advanced additive manufacturing solutions tailored for energy & clean tech applications.

- Support aggressive development timelines in the renewable energy sector through advanced additive manufacturing solutions tailored for energy & clean tech applications.

- Manufacture custom brackets and housings for field installations through advanced additive manufacturing solutions tailored for energy & clean tech applications.

UL Compliance

Electrical component certification for safety and performance

Environmental Testing

IP rating validation for outdoor and harsh environment applications

Material Certifications

Documented material properties for energy-critical applications

Thermal Validation

Performance testing for high-temperature energy applications

Manufacturing Capabilities

Advanced Energy & Clean Tech Solutions

From precision prototyping to full-scale production, our comprehensive capabilities deliver results that transform energy & clean tech manufacturing.

Enclosures, trays, thermal interfaces, and cable management systems—printed in durable, temperature-tolerant materials for rapid validation and testing. Accelerate electric vehicle development with specialized components designed for next-generation energy storage.

EV & Battery System Components. Lead time: 1-3 days.

Technical Specifications

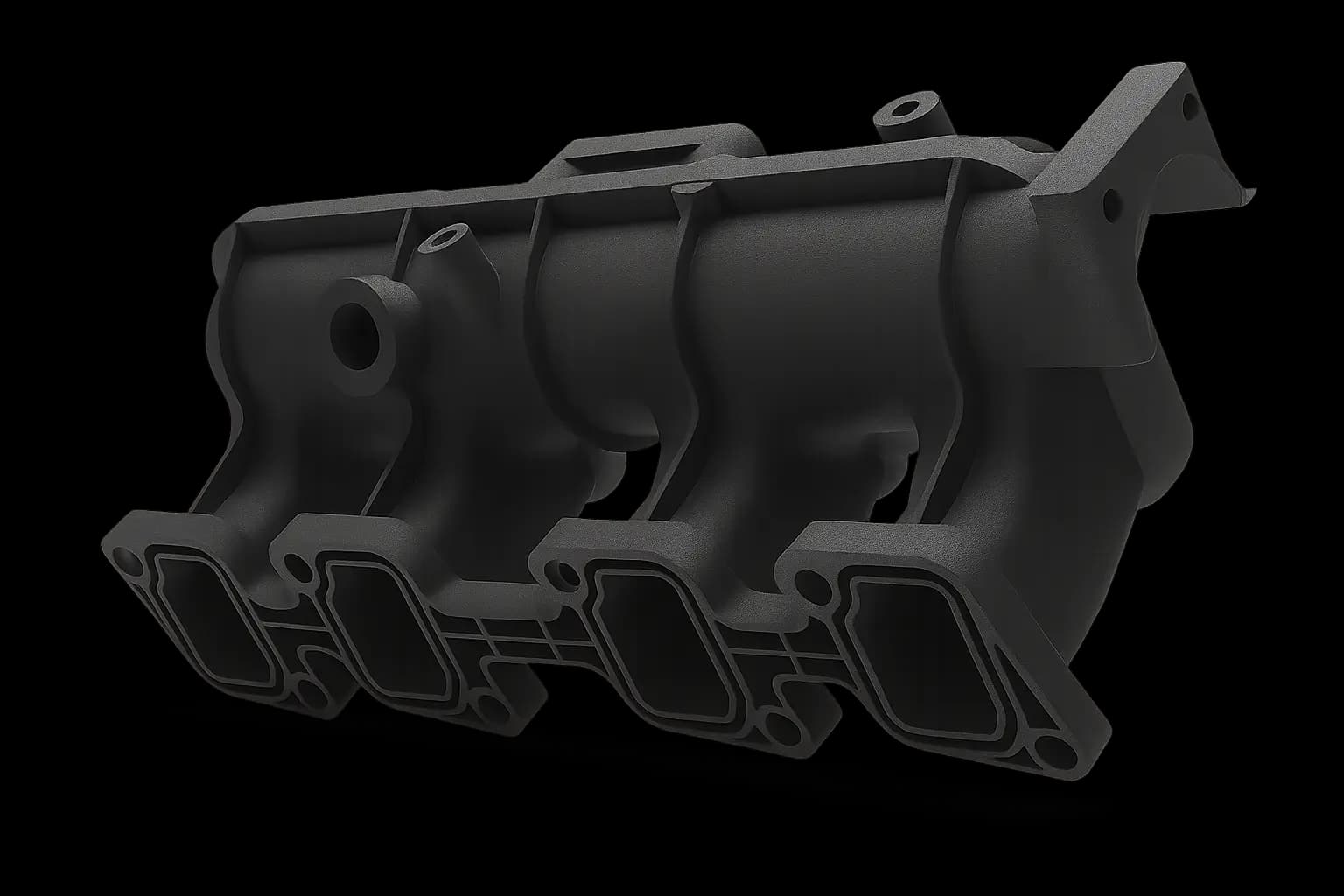

Mounting hardware, airflow components, and internal assemblies with complex internal channels or custom geometries for hydrogen applications. Support the hydrogen economy with precision-manufactured components.

Fuel Cell & Hydrogen Systems. Complex internal geometries.

Technical Specifications

Mounting brackets, connectors, housings, and test fixtures printed with high-strength polymers for field-ready durability and weather resistance. Enable rapid deployment of renewable energy systems.

Solar & Renewable Infrastructure. UV-stable materials.

Technical Specifications

Custom housings, heat sinks, and electrical components for grid-scale energy storage, inverters, and power distribution systems. Support the modernization of electrical infrastructure with advanced manufacturing.

Power Electronics & Grid Components. EMI/RFI shielding capability.

Technical Specifications

Specialized components for battery systems, capacitor banks, and energy storage infrastructure requiring precise thermal and electrical properties. Enable next-generation energy storage with custom-designed components.

Energy Storage Solutions. Thermal runaway protection.

Technical Specifications

Custom jigs, alignment fixtures, and production aids tailored for small batch manufacturing or legacy system support in energy applications. Streamline energy component assembly with specialized tooling.

Production Tooling & Assembly Aids. Custom assembly fixtures.

Technical Specifications

Case Studies

Success Stories

Real results from our energy & clean tech partnerships

EV Battery Thermal Management

Rapid prototyping of cooling manifolds for electric vehicle battery packs, reducing development time by 60%.

Certified Materials

Energy & Clean Tech-Grade Materials

High-performance materials engineered and certified for demanding energy & clean tech applications with full traceability and compliance documentation.

Nylon PA12

Energy & Clean Tech grade

Chemical resistant polymer

- Sustainable manufacturing

- High-performance properties

- Recyclable material

Glass Filled Nylon

Energy & Clean Tech grade

Lightweight structural components

- Reduced material usage

- High strength-to-weight ratio

- Sustainable composite

Accura ClearVue

Energy & Clean Tech grade

Transparent optical components

- UV-stable formulation

- Clean manufacturing process

- High detail resolution

ULTEM 1010

Energy & Clean Tech grade

High-temperature performance

- Chemical resistance

- Long-term durability

- Environmental stability

TPU 88A

Energy & Clean Tech grade

Flexible seals and gaskets

- Chemical resistance

- Long-term elasticity

- Environmental compliance

PC-ABS

Energy & Clean Tech grade

High impact resistance

- Temperature stability

- Chemical resistance

- Dimensional accuracy

Aluminum 6061

Energy & Clean Tech grade

Lightweight metal components

- Corrosion resistance

- Recyclable material

- Sustainable manufacturing

Explore Our Complete Material Matrix

Compare properties, applications, and certifications across our entire material portfolio. Filter by technology, industry, or specific requirements.

Manufacturing Technologies

Proven Technologies for Energy & Clean Tech

Each technology offers unique advantages for energy & clean tech applications. Choose the right process for your specific requirements.

Selective Laser Sintering (SLS)

Fused Deposition Modeling (FDM)

Direct Metal Laser Sintering (DMLS)

Stereolithography (SLA)

Not sure which technology is right for your project?

Our application engineers can help you select the optimal manufacturing process based on your specific requirements, materials, and timeline.

Ready to Transform Your Energy & Clean Tech Manufacturing?

Upload your CAD files for an instant quote or speak with our application engineers about your specific requirements.

Click to start your quote

STL, STEP, OBJ, 3MF supported | Get instant pricing