PLA

Engineering Grade Material

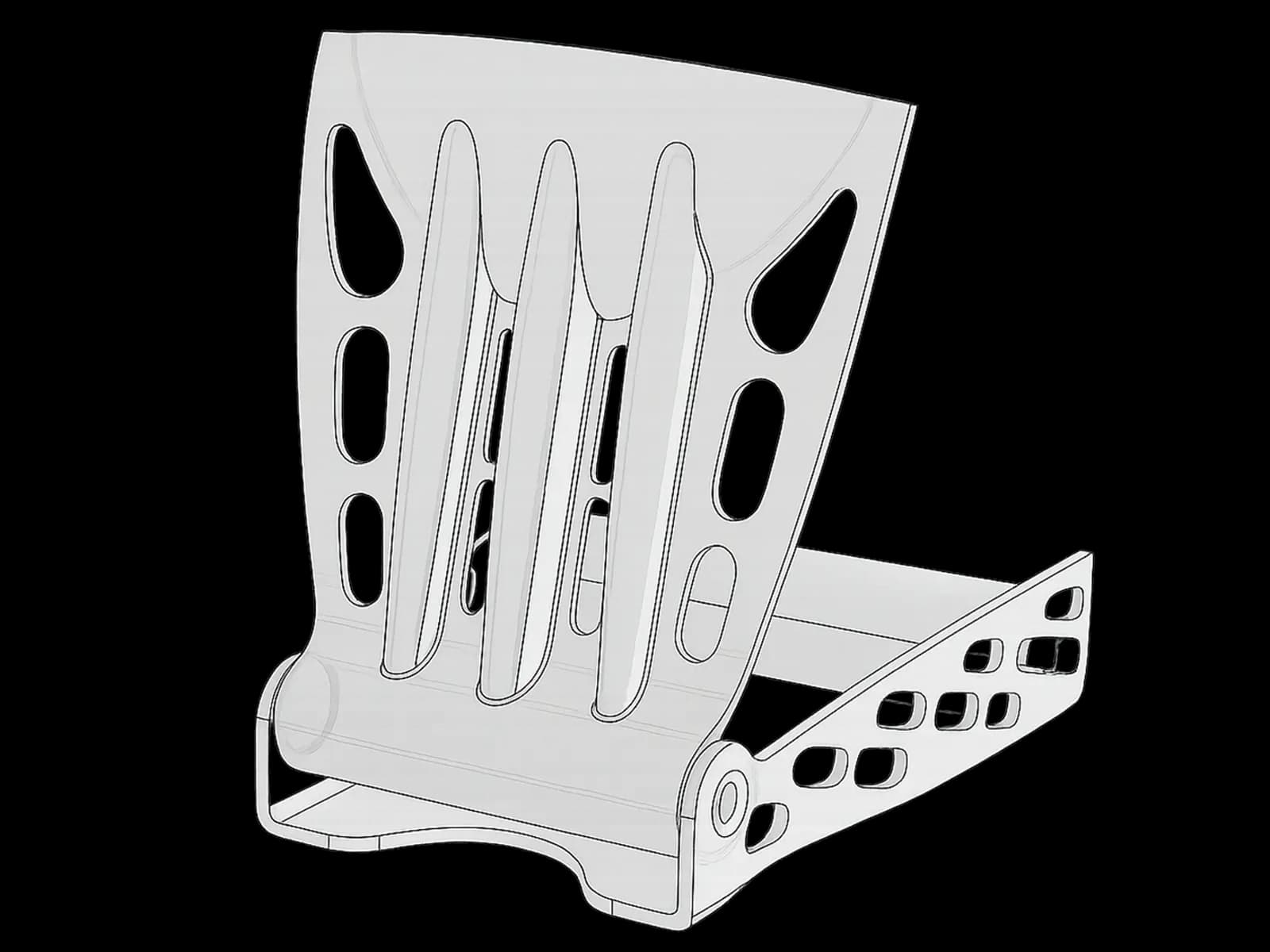

Easy-to-print biodegradable thermoplastic ideal for concept models and visual prototypes

Tensile Strength

See datasheet

Flexural Modulus

See datasheet

Temp Resistance

See datasheet

Applications

Concept models/Visual prototypes/Educational models/Design validation