Accelerate Robotics Developmentwith Advanced 3D Printing

Modern robotics demands lightweight, high-strength, and complex components with short development cycles. Industrial 3D printing delivers unmatched flexibility for rapid iteration and customized geometries. Forge Labs supports robotics 3D printing for functional prototypes, end-use parts, and custom tooling.

Robotics Excellence

Revolutionizing Robotic Component Manufacturing

Modern robotics demands lightweight, high-strength, and complex components—often with short development cycles and highly customized geometries. Industrial 3D printing meets these requirements with unmatched flexibility, enabling rapid iteration, complex design integration, and low-volume production without tooling overhead. At Forge Labs, we've supported robotics companies across Canada and the U.S.—from early-stage prototyping to end-use deployment.

Transforming Robotics Manufacturing

Modern robotics demands lightweight, high-strength, and complex components—often with short development cycles and highly customized geometries. Industrial 3D printing meets these requirements with unmatched flexibility, enabling rapid iteration, complex design integration, and low-volume production without tooling overhead. At Forge Labs, we've supported robotics companies across Canada and the U.S.—from early-stage prototyping to end-use deployment.

Key Benefits of 3D Printing in Robotics

- Design freedom for integrated channels and lattice structures through advanced additive manufacturing solutions tailored for robotics applications.

- Accelerate development timelines and compress design cycles, enabling faster innovation and reduced time-to-market.

- Lightweighting without sacrificing strength or performance through advanced additive manufacturing solutions tailored for robotics applications.

- Eliminate expensive tooling requirements, reducing upfront investments and enabling economical low-volume production.

- Functional prototypes for real-world performance testing through advanced additive manufacturing solutions tailored for robotics applications.

- Custom geometries impossible with traditional manufacturing through advanced additive manufacturing solutions tailored for robotics applications.

Industrial Robot Safety

Compliance with ISO 10218 and ANSI/RIA R15.06 safety standards for industrial robotics applications and human-robot interaction.

Performance Testing

Comprehensive mechanical testing including load, fatigue, and environmental validation for robotic operating conditions.

Material Specifications

Engineering-grade materials with documented mechanical properties, wear resistance, and long-term durability data.

Rapid Iteration Capability

Proven design-to-deployment workflow enabling multiple prototype iterations within days for accelerated development cycles.

Manufacturing Capabilities

Advanced Robotics Solutions

From precision prototyping to full-scale production, our comprehensive capabilities deliver results that transform robotics manufacturing.

Design and manufacture application-specific end effectors with integrated pneumatic channels, custom grip geometries, and lightweight materials. Our technologies enable rapid prototyping of gripper designs optimized for specific tasks, with the ability to iterate quickly based on real-world testing and performance requirements.

Relevant Technologies

Custom End Effectors & Grippers. Custom grip geometries.

Technical Specifications

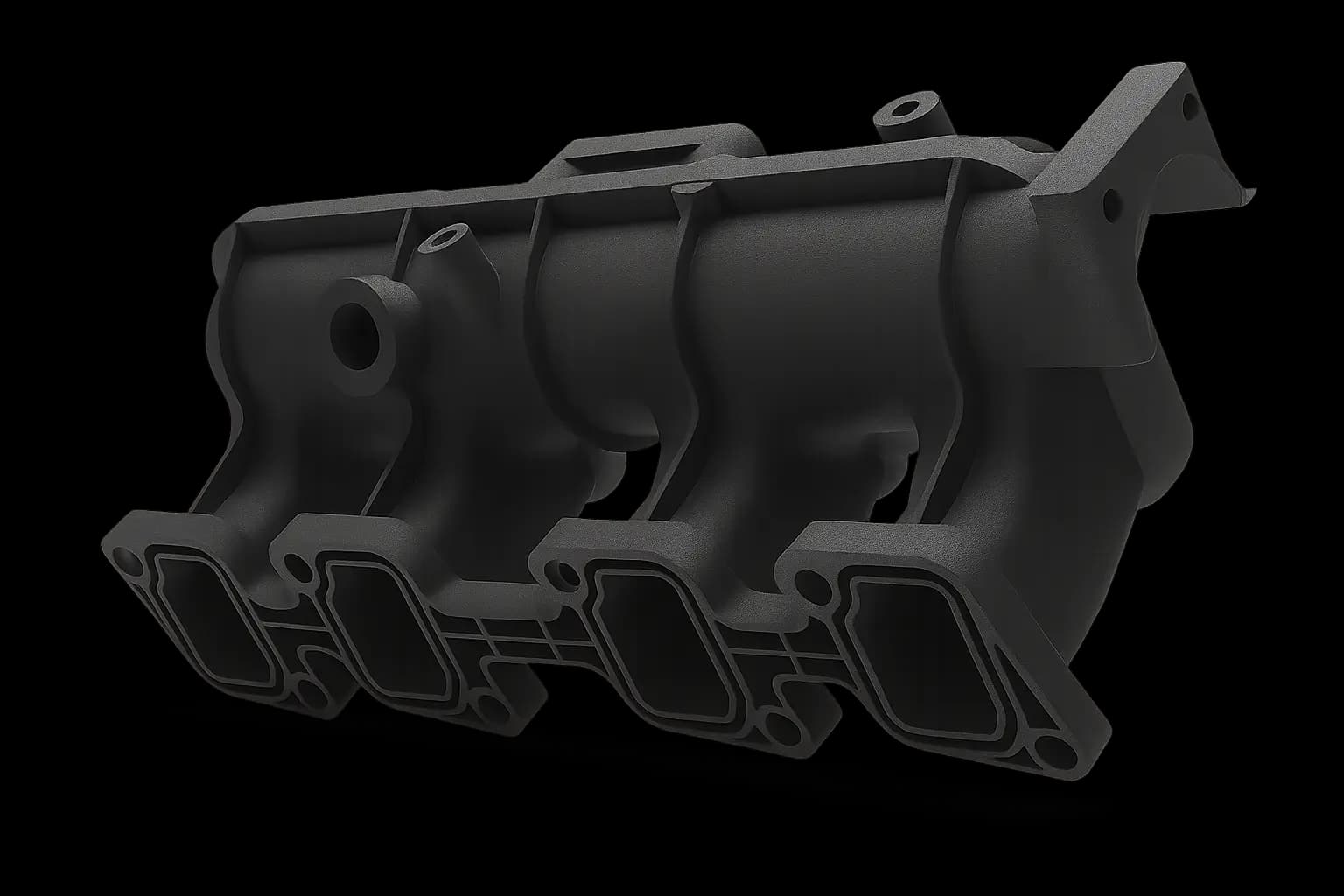

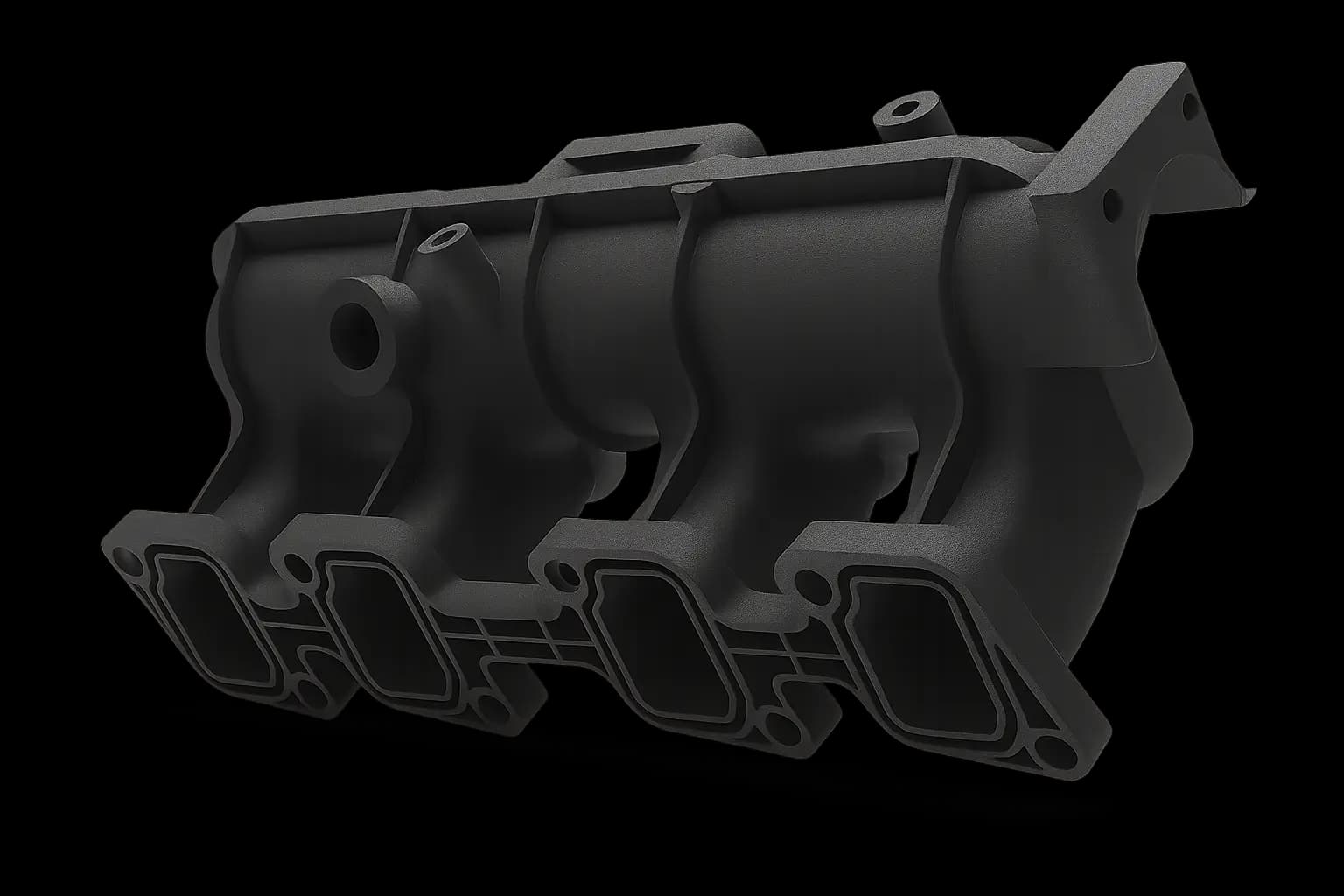

Produce lightweight, integrated mounting solutions for vision systems, LIDAR, and sensor arrays. Create custom housings with precise optical alignment features, integrated cable management, and environmental protection while maintaining minimal weight impact on robotic systems.

Sensor & Camera Mounting Systems. Precise optical alignment.

Technical Specifications

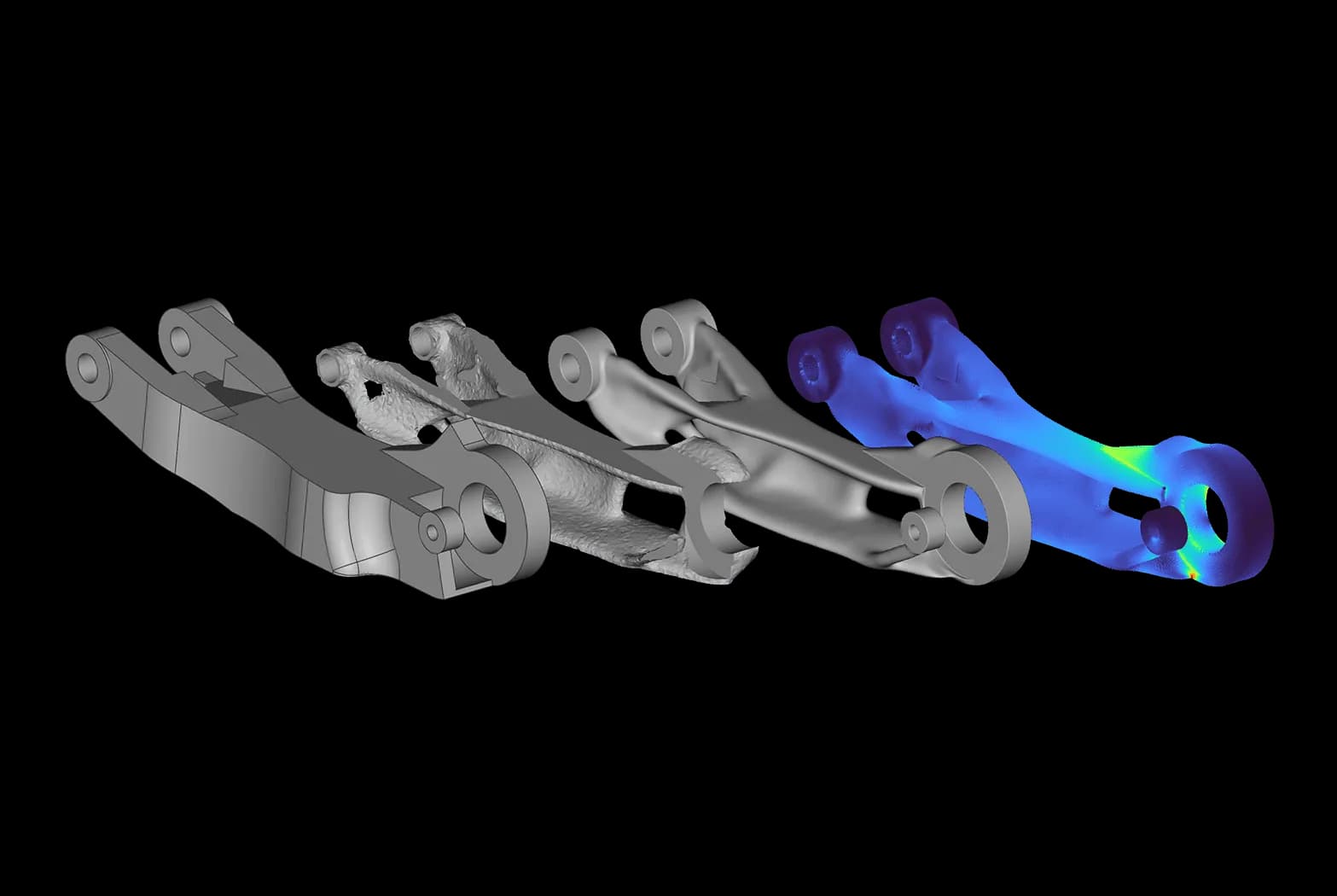

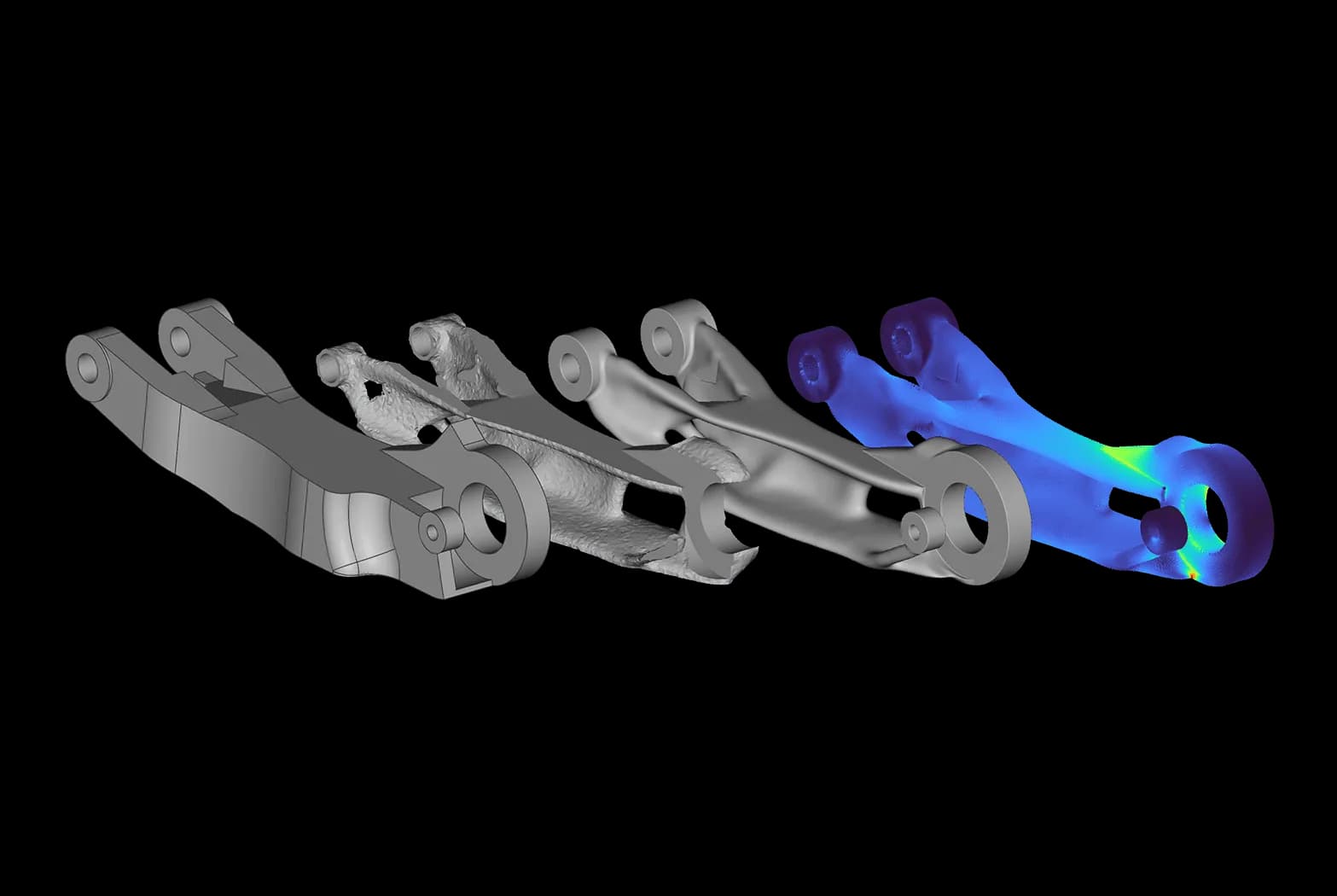

Engineer optimized structural components for drones, autonomous robots, and mobile platforms using topology optimization and lattice structures. Achieve maximum strength-to-weight ratios while incorporating mounting points, cable routing, and component integration in single-piece designs.

Lightweight Structural Frames. Topology optimization ready.

Technical Specifications

Our technologies enable production of parts not just for visual validation, but for real-world performance testing and deployment. Test mechanical properties, thermal performance, and functional integration before committing to production tooling or design finalization.

Functional Prototypes & Testing. Real-world performance testing.

Technical Specifications

Create custom jigs, fixtures, and assembly tools for robotic manufacturing and calibration. Design specialized tooling for robot assembly lines, testing fixtures for quality control, and alignment tools for precision assembly operations.

Production Tooling & Assembly Fixtures. Custom assembly solutions.

Technical Specifications

Design integrated cable management systems with internal routing channels, snap-fit connections, and protective enclosures. Create rugged, test-ready chassis and protective housings for electronic components in demanding robotic environments.

Cable Management & Enclosures. Internal routing channels.

Technical Specifications

Case Studies

Success Stories

Real results from our robotics partnerships

Autonomous Mobile Robot End Effector System

Developed custom gripper system for warehouse automation robot, integrating pneumatic channels, force sensors, and adaptive grip geometry. Achieved 50% weight reduction compared to machined alternative while improving grip versatility and reducing assembly complexity.

Drone Racing Frame Optimization

Engineered lightweight carbon fiber reinforced frame for competitive drone racing, using topology optimization to achieve maximum strength-to-weight ratio. Reduced frame weight by 40% while improving crash resistance and integrating cable management systems.

Certified Materials

Robotics-Grade Materials

High-performance materials engineered and certified for demanding robotics applications with full traceability and compliance documentation.

Nylon PA12

Robotics grade

High-strength polymer

- Structural robot components

- Excellent wear resistance

- Chemical resistance

Carbon Fiber Nylon

Robotics grade

Lightweight composite

- High-performance frames

- Superior mechanical properties

- Excellent dimensional stability

Accura ClearVue

Robotics grade

Transparent resin

- Optical components and sensors

- High-detail resolution

- UV-stable formulation

Aluminum 6061

Robotics grade

Structural metal alloy

- Rigid mounting brackets

- Excellent strength-to-weight ratio

- Good corrosion resistance

TPU

Robotics grade

Flexible polymer

- Grippers and shock absorbers

- Excellent tear resistance

- Compliant mechanisms

Glass Filled Nylon

Robotics grade

Reinforced polymer

- Enhanced stiffness and strength

- Dimensional stability

- Industrial grade performance

Explore Our Complete Material Matrix

Compare properties, applications, and certifications across our entire material portfolio. Filter by technology, industry, or specific requirements.

Manufacturing Technologies

Proven Technologies for Robotics

Each technology offers unique advantages for robotics applications. Choose the right process for your specific requirements.

Selective Laser Sintering (SLS)

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Direct Metal Laser Sintering (DMLS)

Not sure which technology is right for your project?

Our application engineers can help you select the optimal manufacturing process based on your specific requirements, materials, and timeline.

Ready to Transform Your Robotics Manufacturing?

Upload your CAD files for an instant quote or speak with our application engineers about your specific requirements.

Click to start your quote

STL, STEP, OBJ, 3MF supported | Get instant pricing