Local 3D Printing & Manufacturing in Victoria

Local Manufacturing Partner for Government & Marine Industries

Serve Vancouver Island's marine, government, and technology sectors with precision 3D printing solutions. From marine equipment to government applications, rapid manufacturing with island-wide delivery.

Marine to government workflows in VictoriaProduction-ready 3D printing technologies

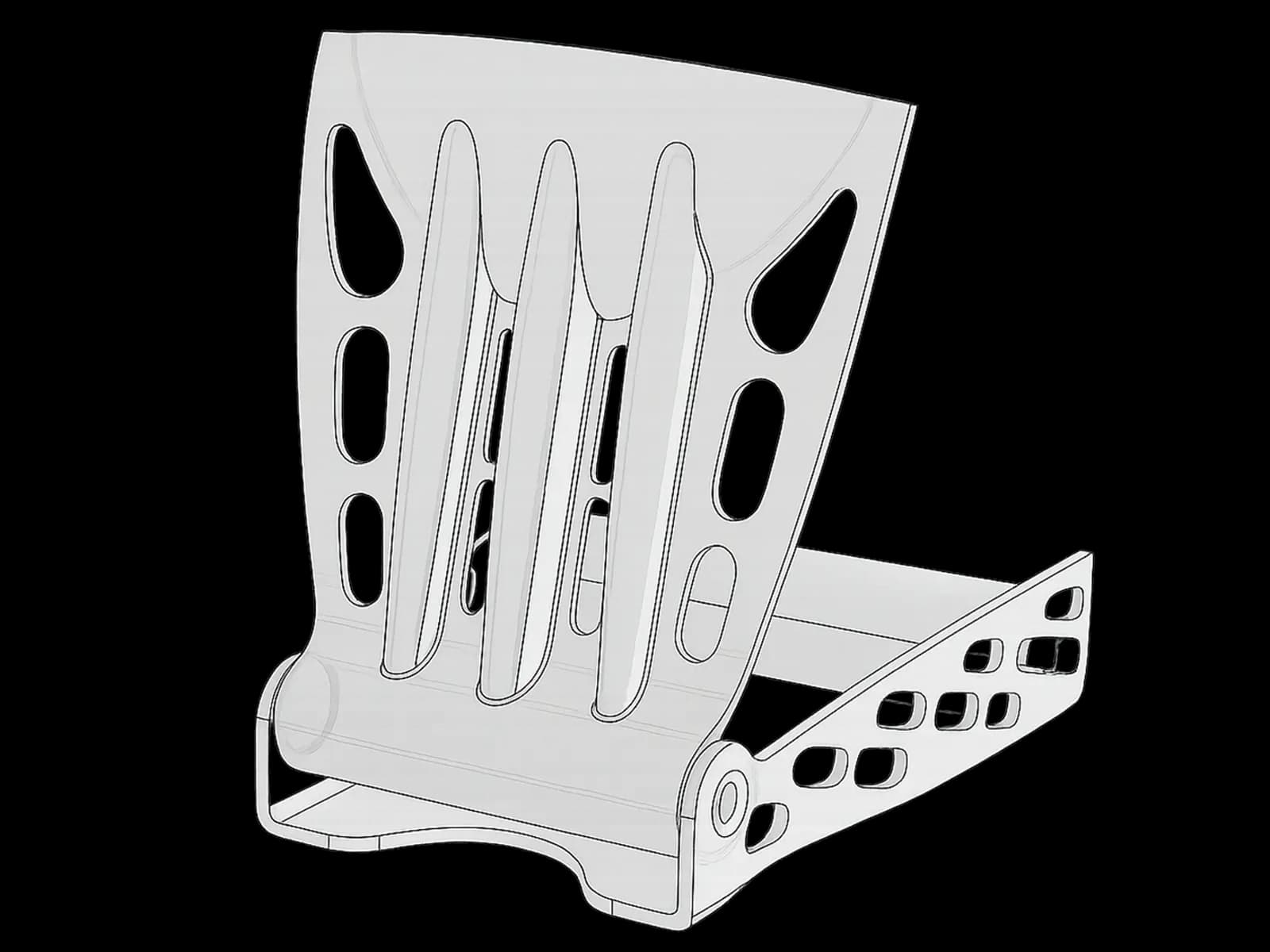

For Victoria's marine and government industries, SLS 3D printing produces high-strength thermoplastic parts with complex geometries and no support structures required. This reliable technology offers exceptional isotropic properties, perfect for coastal conditions and specialized applications. Its ability to create complex internal features without supports enables corrosion-resistant designs ideal for marine environments.

Learn more about Selective Laser SinteringAvailable materials

Your Vancouver Island Manufacturing Partner

From Victoria's government and marine center, we serve Vancouver Island's diverse sectors including marine industries, government operations, and growing technology companies.

Industrial Manufacturing Excellence

Victoria's economy combines government operations, marine industries, and emerging technology sectors. Vancouver Island's geographic isolation creates unique manufacturing and logistics challenges that require specialized solutions.

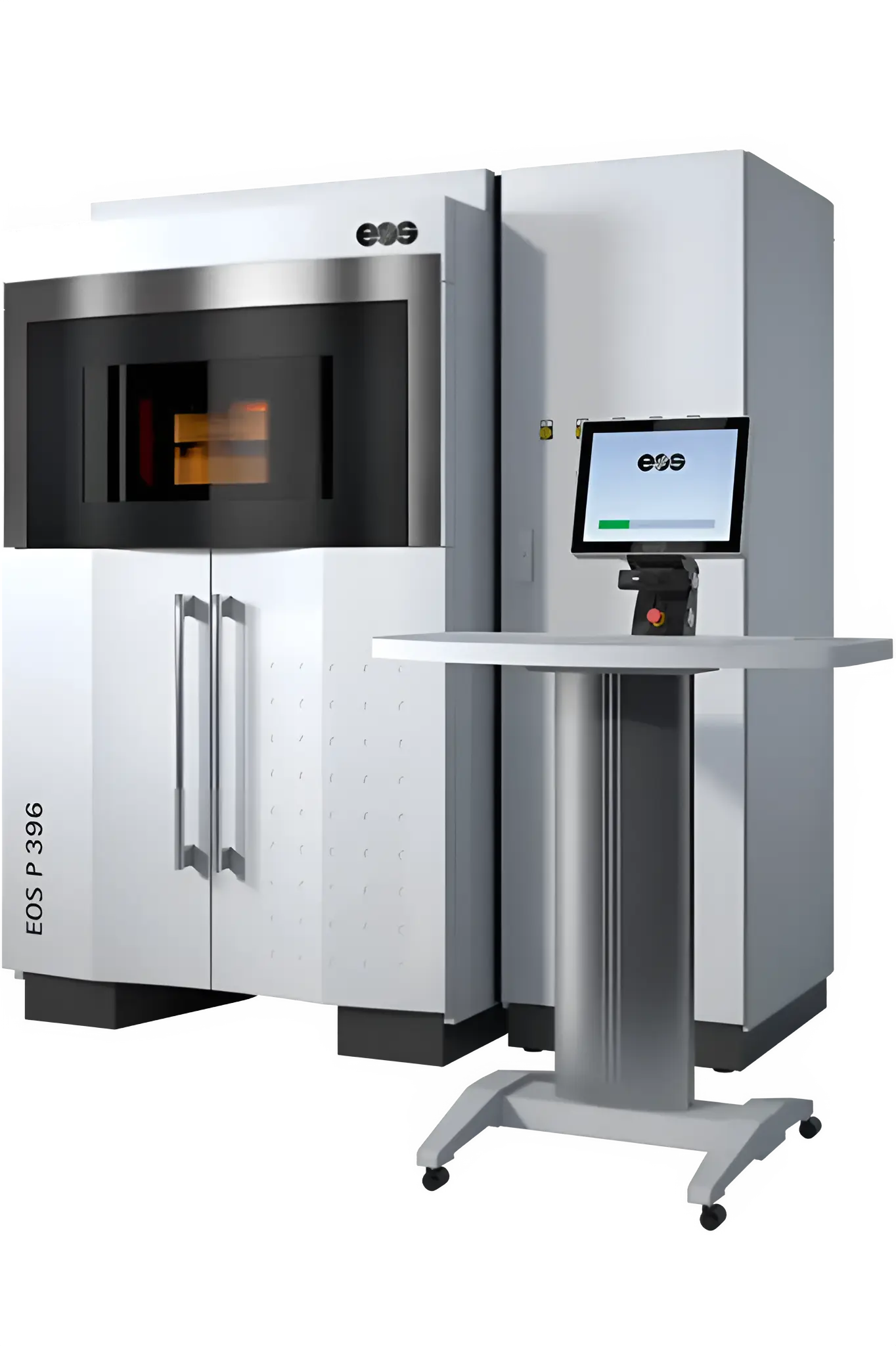

EOS, 3D Systems & HP Industrial Systems

Tier-1 production equipment for demanding applications

Canadian Manufacturing Network

Multi-facility production for scalable capacity

Made in Canada Certification

Domestic production for supply chain security

1-500+ Parts Seamlessly

Network capacity eliminates production bottlenecks

State-of-the-Art Technology

Our advanced 3D printing technologies operate 24/7, ensuring continuous production without reliance on external vendors. By housing all manufacturing technologies in-house, we minimize lead times, eliminate supply chain delays, and maintain full quality control.

From rapid prototyping to full-scale production, our automated systems ensure fast turnaround times while maintaining the highest industry standards for Victoria and British Columbia.

Quality You Can See

Our manufacturing processes understand the demanding requirements of marine applications where corrosion resistance, durability, and regulatory compliance are essential for operational success in coastal environments.

Performance You Can Trust

ISO 9001:2015 Based QMS

Ensuring material traceability and precision at every stage of production

Statistical Quality Control

ISO-2859 inspection standards for consistent batches

First Article Inspection

Validating production before full-scale manufacturing

In-House Manufacturing

Complete control eliminates third-party delays in Victoria

Dimensional Reports

Detailed verification of design specifications

Visual Inspection

Cosmetic quality assessment for every part

Instant Quote Tool

Instant Online 3D Printing in Victoria

75% complete

Simple File Upload Process

Drag and drop your 3D files or browse to upload. Our system automatically analyzes your designs and provides instant feedback on printability and optimization suggestions.

- Drag & drop multiple file formats

- Automatic design analysis

- Printability feedback

- File optimization suggestions

1 part or 1,000

Rapid prototyping to full-scale production, our systems keep programs moving while the same engineers guide each phase. Upload files for instant quotes or collaborate with our team to select the right mix of 3D printing materials and technologies for your build. Every build follows the same validated path: intake, qualification, automated production, and inspection, so your prototypes hand off to production without rework.

Rapid intake with engineer-led DFM review

One-hour engineering response

Engineers at our Victoria facility audit every CAD submission within one business hour, preserving assemblies, units, and intent before we commit machines.

- Secure drag-and-drop uploads with checksum verification and revision history.

- Automated geometry analysis paired with engineer review for actionable feedback.

- Design notes stay beside every part so your team and ours stay in sync.

Qualification builds that lock in repeatable settings

Parameters captured, documented, and versioned

Calibration builds, coupon testing, and laser tuning are documented so the same recipe carries from EVT through production without surprises.

- DMLS, SLS, MJF, SLA, and FDM process windows recorded inside our QMS.

- CP and CPK monitoring supports aerospace, medical, and automotive programs.

- Material lot traceability maintained from powder to finished part.

Lights-out manufacturing with real-time scheduling

Parallel cells for polymers and metals

Automated nesting, powder conditioning, and scheduling keep our Victoria production cells running 24/7 so prototype batches scale into production as soon as you give the go-ahead.

- Dedicated SLS, MJF, SLA, and FDM bays with on-call technicians.

- Integrated finishing lines for dye, paint, vapor smoothing, machining, and assembly.

- Live dashboards expose machine availability and expected ship dates.

Integrated documentation, quality control, and delivery

Automated traceability tied to every shipment

Steam captures batch control, material genealogy, and inspection data automatically at our Victoria facility, so FAIR packages, process documentation, and shipping confirmations are ready the moment parts leave the lab.

- Automated traceability linking powder lots, machine parameters, and technician sign-offs.

- FAI, PPAP, and custom documentation templates available on request.

- Courier, freight, and global logistics managed with real-time notifications.

Quality you can see

Forge Labs Steam orchestrates quoting, manufacturability feedback, and order execution, but every part still meets our quality lab before it ships. Automation accelerates the paperwork; engineers close the loop with metrology, documentation, and cosmetic sign-off.

Steam's DFM intelligence flags risks instantly, while our manufacturing engineers adjust builds, tooling, and documentation so production stays compliant across every repeat run.

ISO 9001:2015-Ready QMS

Closed-loop traceability with controlled document revisions and corrective actions on every order.

Statistical quality control

ISO-2859 sampling plans and Cp/Cpk monitoring keep production builds within spec.

First article inspection

Dimensional and functional validation before we transition any program into sustained production.

In-house manufacturing cells

Dedicated polymer and metal teams blend automation with hands-on engineering oversight.

Dimensional reports

GR&R qualified metrology delivers CAD-overlaid reports and revision history for auditors.

Visual and cosmetic sign-off

Surface, color, and assembly checks confirm presentation-ready hardware every shipment.

Talk with our manufacturing engineers

Bring your next program into Forge Labs Steam, from prototype intake to sustained production with audit-ready quality.

Trusted by the most innovative teams

Engineering, procurement, and operations teams use Forge Labs Steam to upload CAD, run instant manufacturability checks, and lock pricing in seconds—without inbox tag or manual back-and-forth.

Industries We Serve in Victoria

Victoria's strategic location and skilled workforce create unique opportunities for advanced manufacturing. 3D printing technology enables local industries to accelerate innovation, reduce costs, and bring products to market faster.

How 3D Printing is Transforming Victoria's Manufacturing Landscape

Victoria's strategic location and skilled workforce have positioned the city as a manufacturing hub. Now, with advanced 3D printing technologies, local companies are experiencing unprecedented capabilities in rapid prototyping, custom manufacturing, and low-volume production that were previously impossible or prohibitively expensive.

From aerospace components to medical devices, Victoria businesses across 0+ key industries are leveraging 3D printing to reduce lead times, eliminate tooling costs, enable complex geometries, and bring innovative products to market faster than traditional manufacturing allows.

Transformation in Action

Marine & Shipbuilding Manufacturing in Victoria

Victoria's marine industry leverages 3D printing for custom boat components, marine hardware, and specialized equipment designed for Pacific Northwest marine conditions and saltwater environments. This transformation is enabling Victoria companies to compete globally while reducing costs and accelerating innovation cycles.

Build Supply Chain Resilience in Victoria

Victoria, British Columbia companies face increasing pressure to reduce supply chain risks while maintaining competitive costs and delivery times. Forge Labs provides local manufacturing solutions that eliminate dependency on distant suppliers while reducing costs and lead times.

Traditional Supply Chain Risks

Long Lead Times

Global supply chains can take weeks or months, slowing innovation and increasing inventory costs

Supply Disruptions

Single points of failure in overseas suppliers can halt production unexpectedly

Minimum Order Quantities

Traditional suppliers require large orders, creating cash flow and storage challenges

Impact on Victoria Companies:

Higher inventory costs, slower innovation cycles, and vulnerability to global disruptions

Local Manufacturing Solutions

Rapid CNC Machining

Local precision manufacturing for critical components with same-day to 3-day turnaround

On-Demand 3D Printing

Digital inventory eliminates the need for physical stock of complex, low-volume parts

Local Manufacturing Network

Distributed production capabilities across Canada reduce dependency on single sources

Perfect for Victoria:

Supporting local manufacturers and technology companies with agile, local manufacturing solutions

Proven Supply Chain Agility

When global supply chains face disruptions, companies with local manufacturing partnerships maintain operations while competitors struggle. 3D printing and CNC machining provide the flexibility to adapt quickly to changing requirements.

Our Victoria customers benefit from single-step manufacturing with low setup costs, rapid prototyping capabilities, and the ability to produce both high-precision machined parts and complex geometries without traditional tooling constraints.

Ready to build supply chain resilience for your Victoria operations?

Ready to Get Started?

Upload your design and get an instant quote for your 3D printing project.

Click to start your quote

STL, STEP, OBJ, 3MF supported | Get instant pricing

Frequently Asked Questions

Common questions about our 3D printing services in Victoria

- What types of 3D printing technologies are available in Victoria?

- We offer 6 advanced 3D printing technologies in Victoria, including Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Stereolithography (SLA), Fused Deposition Modeling (FDM), Multi Jet Fusion (MJF), and PolyJet printing. Each technology is optimized for different applications and materials.

- What materials are offered for 3D printing in Victoria, and how do I choose the right one for my project?

- We offer 50+ advanced materials including high-performance polymers, engineering plastics, biocompatible resins, and metal alloys. Our material selection tool and expert team can help you choose the optimal material based on your application requirements, mechanical properties needed, and budget considerations.

- What is the typical turnaround time for 3D printing orders in Victoria?

- Our minimum lead time in Victoria is 24 hours for standard parts, with most orders completed within 2-5 business days. Rush orders can often be accommodated with same-day or next-day delivery across British Columbia. Lead times depend on part complexity, material selection, and order volume.

- Can I get a prototype 3D printed before committing to a larger production run?

- Absolutely! We encourage prototyping before production runs. Our instant quoting system allows you to order single prototypes to test fit, form, and function. Once you're satisfied with the prototype, scaling to production quantities of 10, 100, or 1000+ parts is seamless with consistent quality.

- What are your lead times for Victoria orders?

- Standard lead times in Victoria are 2-5 business days for most orders. We offer expedited 24-48 hour turnaround for urgent projects, and complex or large volume orders may require 5-10 business days. All orders include island-wide delivery across Vancouver Island to ensure you receive your parts quickly.