Step 1 of 4

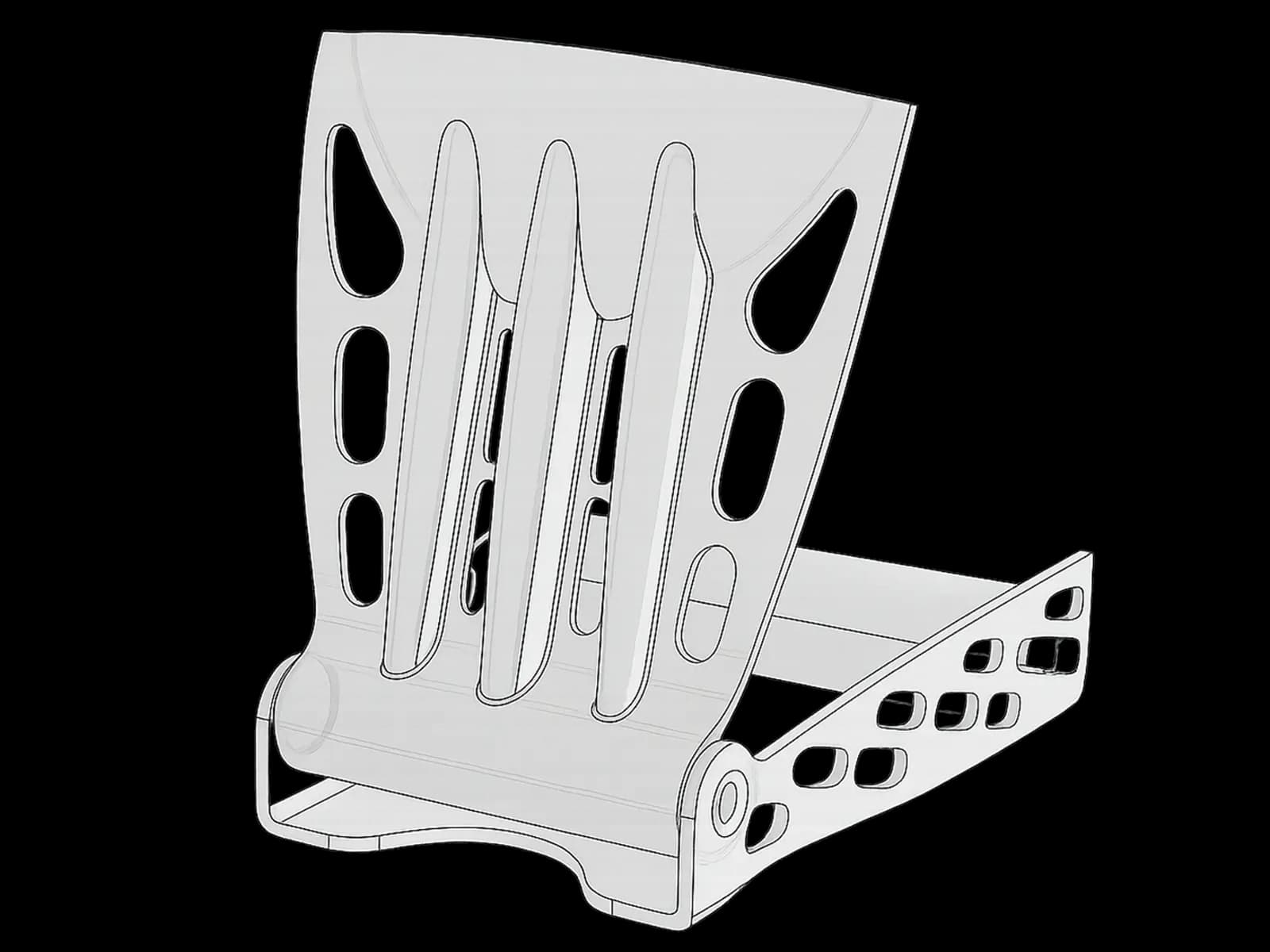

Programming and DFM Review

Engineering team reviews CAD files, optimizes toolpaths, and develops fixture strategy to balance precision and efficiency.

- File Formats

- STEP, IGES, Parasolid, Native CAD

- Review Time

- Same day to 24 hours

- DFM Output

- Toolpath strategy and fixture plan

- Quality Plan

- Inspection checkpoints defined