Multi-Jet Fusion3D Printing for High-Performance Prototypes & End-Use Parts

Precision engineering with fine detail resolution and excellent surface quality. Production-grade materials like PA12 & glass-filled nylons for strength and durability. Scalable for low-to-mid-volume manufacturing with cost-efficient batch production. MJF is widely used for functional prototypes and end-use parts where repeatability and throughput matter.

Technology Overview

High-Speed Production 3D Printing

MJF combines speed with quality through parallel processing technology. Ideal for rapid prototyping and scalable production with consistent mechanical properties and excellent surface finish.

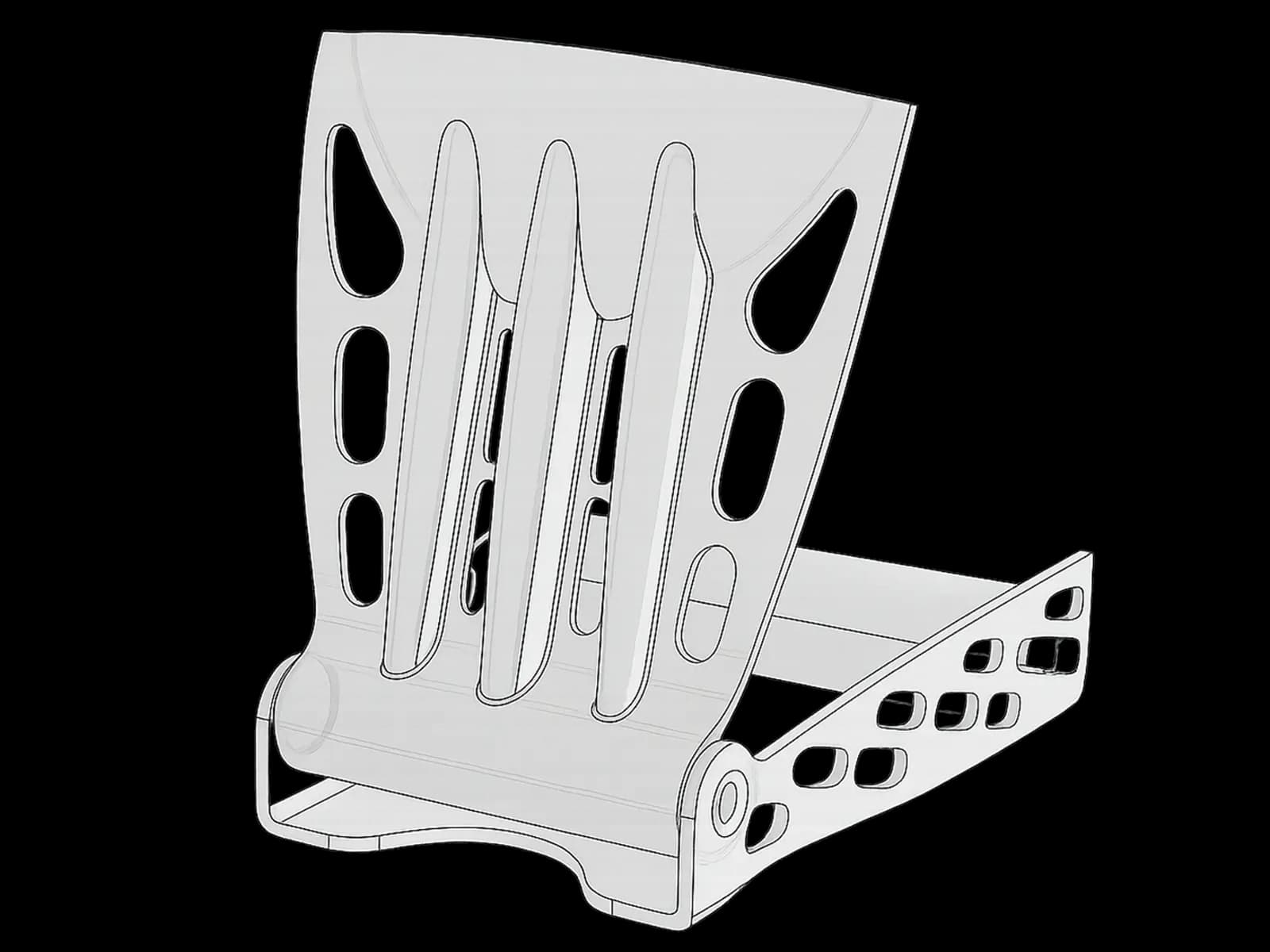

Advanced manufacturing capabilities enable complex geometries, functional prototypes, and end-use production parts that would be impossible or cost-prohibitive with traditional manufacturing methods. From functional prototypes to end-use production parts, this technology delivers exceptional performance across demanding industries.

Production Applications

1 to 1000+ Parts Built in Hours

Engineered for high-volume production with consistent mechanical properties across thousands of parts, MJF technology delivers production-grade components with excellent surface finish and dimensional accuracy. The thermal fusion process enables rapid part consolidation with up to 80% powder reusability, making it cost-effective for batch production. Industries rely on MJF for functional prototypes, end-use parts, and custom manufacturing where speed and consistency are critical.

End Use Parts for High-Performance Applications

Production workflows benefit from MJF's unique ability to nest hundreds of parts efficiently within each build, maximizing throughput while maintaining consistent quality. The thermal inkjet process applies fusing and detailing agents with precision, creating smooth surfaces and sharp edges without traditional support structures. Real-time monitoring and closed-loop control systems ensure every part meets stringent quality standards for batch production and regulatory compliance.

Key Advantages

Complex Geometries: Intricate internal channels, overhangs, and assemblies impossible with traditional manufacturing.

Functional Prototypes: Test mechanical properties and fit before investing in production tooling.

Custom Tooling: Jigs, fixtures, and manufacturing aids tailored to specific production requirements.

End-Use Parts: Production components for aerospace, medical, automotive, and industrial applications.

The Multi-Jet Fusion (MJF) manufacturing process

Multi-Jet Fusion technology delivers superior speed and quality through its unique parallel processing approach, making it ideal for both rapid prototyping and scalable production. Fusing and detailing agents are jetted across the powder bed, then infrared energy bonds the material for uniform properties. Parts are depowdered and bead blasted or dyed to achieve the final surface finish.

Powder Bed Preparation

A thin, uniform layer of powdered thermoplastic material is spread across the heated build platform using precision spreading mechanisms.

Step Specifications

- Build Volume (mm)

- 380 × 284 × 380

- Tolerance

- ±0.3

- Layer Height (μm)

- 80 microns

- Materials Available

- 2+

No support structures, so parts can stack vertically for maximum packing density.

Predictable shrink compensation delivers repeatable production accuracy.

Thin, uniform layers for smooth surfaces at production speed.

PA12/PA11 families plus elastomers for production-grade parts.

High Throughput MJF Materials

High-throughput MJF materials combine speed with quality, delivering functional parts with excellent mechanical properties. Our PA12 and PA11 materials offer superior surface finish and dimensional accuracy for both prototyping and production runs.

HP MJF PA12

Engineering Grade Material

Highly durable Nylon 12 with excellent surface resolution and high density (98%). High strength-to-weight ratio with resistance to harsh environments. Watertight and meets USP Class I-VI and US FDA guidance for biocompatibility.

Applications:

HP MJF PA12 Glass Filled

High Rigidity Glass Filled

Glass fiber reinforced Nylon 12 designed for enhanced stiffness, thermal resistance, and dimensional stability. 20% glass fiber content provides superior rigidity and reduced warping under load.

Applications:

Material Surface Finishes

MJF parts have a smooth, matte surface with a slightly grainy texture due to the powder-based printing process. Unlike FDM, MJF does not produce visible layer lines, resulting in a more uniform and professional appearance straight from the printer. At Forge Labs, bead blasting is performed as a standard post-processing step to remove excess powder and refine the surface texture.

Standard Finish

Natural Grey

MJF parts are delivered with a standard bead-blasted finish in natural grey. This process removes excess powder and slightly smooths the surface while maintaining the material's natural matte texture.

Finish Attributes

Deep Color Dye

Dyed Black

Specialized dye bath creates deep, uniform black color that chemically bonds with the nylon material. Unlike painted finishes, the dye fully penetrates the surface and won't chip or wear off over time.

Finish Attributes

Vapor Smoothing

Enhanced Finish

Advanced chemical smoothing technique that enhances surface quality by slightly melting and redistributing the surface material, eliminating grainy texture and sealing porous areas.

Finish Attributes

Performance Paint

Custom Finish

Automotive-grade coating that enhances aesthetics and durability. Hand-finished for smooth surfaces with professional-grade equipment. Custom color matching available for precise branding needs.

Finish Attributes

Multi-Jet Fusion Design Guidelines

Essential design considerations to optimize your Multi-Jet Fusion parts for manufacturing success.

Maximum Build Volume

380 x 284 x 380 mm (15 x 11.2 x 15 inches)

If your parts require specific tolerances, please include an engineering drawing along with the part. Parts designed with large flat planes will likely warp, so this should be avoided if tight tolerances are required.

Parts with large flat surfaces are prone to warping and should be avoided for applications requiring tight tolerances.

Tolerances

Nylon PA 12: ±0.3% (min ±0.5 mm)

If your parts require specific tolerances, please include an engineering drawing along with the part. Parts designed with large flat planes will likely warp, so this should be avoided if tight tolerances are required.

Always provide engineering drawings for parts requiring specific dimensional tolerances. Tolerances differ for Polypropylene: ±1.75% (min ±0.7 mm).

Layer Height

100 Microns

The layer height is the overall Z resolution of the part; we avoid stepping artifacts on important features of your models by orienting the part(s) along the Z plane or at a 20 degree angle on all sides.

Optimal part orientation minimizes visible layer lines on critical surfaces.

Surface Finish

Uniform, Matte

Parts are bead blasted and have a uniform grainy matte texture, similar to ultra-fine sandpaper.

The matte finish provides excellent grip and professional appearance for functional parts.

Advantages of MJF 3D Printing for Prototyping & Production

Multi Jet Fusion (MJF) is an advanced powder-bed 3D printing process that delivers high-speed production, fine detail resolution, and strong, functional parts. The process uses parallel processing technology, making MJF ideal for rapid prototyping, iterative design testing, and scalable production of end-use parts.

- Excellent Detail & Precision

- Fine features, sharp edges, and smooth surfaces achieved through detailing agents and uniform heating.

- High-Speed Production

- Faster than other powder-bed 3D printing processes due to parallel agent deposition and infrared fusion.

- Consistent Mechanical Properties

- Uniform fusion process ensures high-strength, isotropic parts with no weak Z-axis layering.

- No Support Structures Needed

- Powder bed supports the part during printing, allowing for complex geometries and high-density builds.

- Scalable for Production

- Enables batch manufacturing with consistent quality, making it cost-effective for low to medium production volumes.

- High Material Efficiency

- Unfused powder is reusable, reducing material waste and lowering overall production costs.

Instant Quote Tool

From Upload to Delivery

75% complete

Simple File Upload Process

Drag and drop your 3D files or browse to upload. Our system automatically analyzes your designs and provides instant feedback on printability and optimization suggestions.

- Drag & drop multiple file formats

- Automatic design analysis

- Printability feedback

- File optimization suggestions

MJF Applications Across Industries

Discover how Multi-Jet Fusion is transforming manufacturing across industries with innovative solutions and enhanced capabilities.

Aerospace Components

Lightweight structural components, complex ducting systems, and functional prototypes requiring high strength-to-weight ratios.

Automotive Manufacturing

Functional prototypes, end-use interior components, tooling, and fixtures for manufacturing processes.

Medical Device Manufacturing

Biocompatible custom prosthetics, surgical guides, and medical device housings with complex internal geometries.

Industrial Design

Consumer product housings, functional prototypes, and batch production of end-use components.

Success Stories

Real results from our MJF manufacturing partnerships

Automotive Interior Dashboard

Complex dashboard assembly with integrated clips and mounting features produced as a single part

Medical Prosthetic Device

Custom prosthetic with patient-specific geometry and integrated mechanical features

Ready to manufacture your parts?

Upload your CAD files to get instant quotes for MJF 3D printing. Professional-grade manufacturing with fast turnaround times.

Click to start your quote

STL, STEP, OBJ, 3MF supported | Get instant pricing

MJF Questions & Answers

Common questions about MJF 3D printing technology. Can't find what you're looking for? Reach out to our technical team.