Quality built into industrial additive manufacturing

Forge Labs is an industrial manufacturing 3D printing platform. Our proprietary MES, Forge Labs Steam, was engineered specifically for additive manufacturing with traceability, batch control, and process documentation that enable ISO 9001 quality systems so production parts stay accessible, fast, and economical.

Steam manages the entire workflow from instant quoting through logistics. The same digital thread keeps engineers, technicians, and customers aligned on every decision while capturing the data quality systems require.

2-4 business days

MES built for ISO 9001

98.7% rolling 12 months

Steam orchestrates every manufacturing step

Our MES was built specifically for additive manufacturing and industrial 3D printing technologies with the traceability and documentation architecture that quality systems require. Steam keeps the process accessible, fast, and economical while delivering the consistency production-grade additive parts demand.

By owning the software and the factory floor, we manage quoting, build scheduling, technician workflows, and logistics inside the same system. There are no third party handoffs and no gaps in accountability.

Detailed DFM before you order

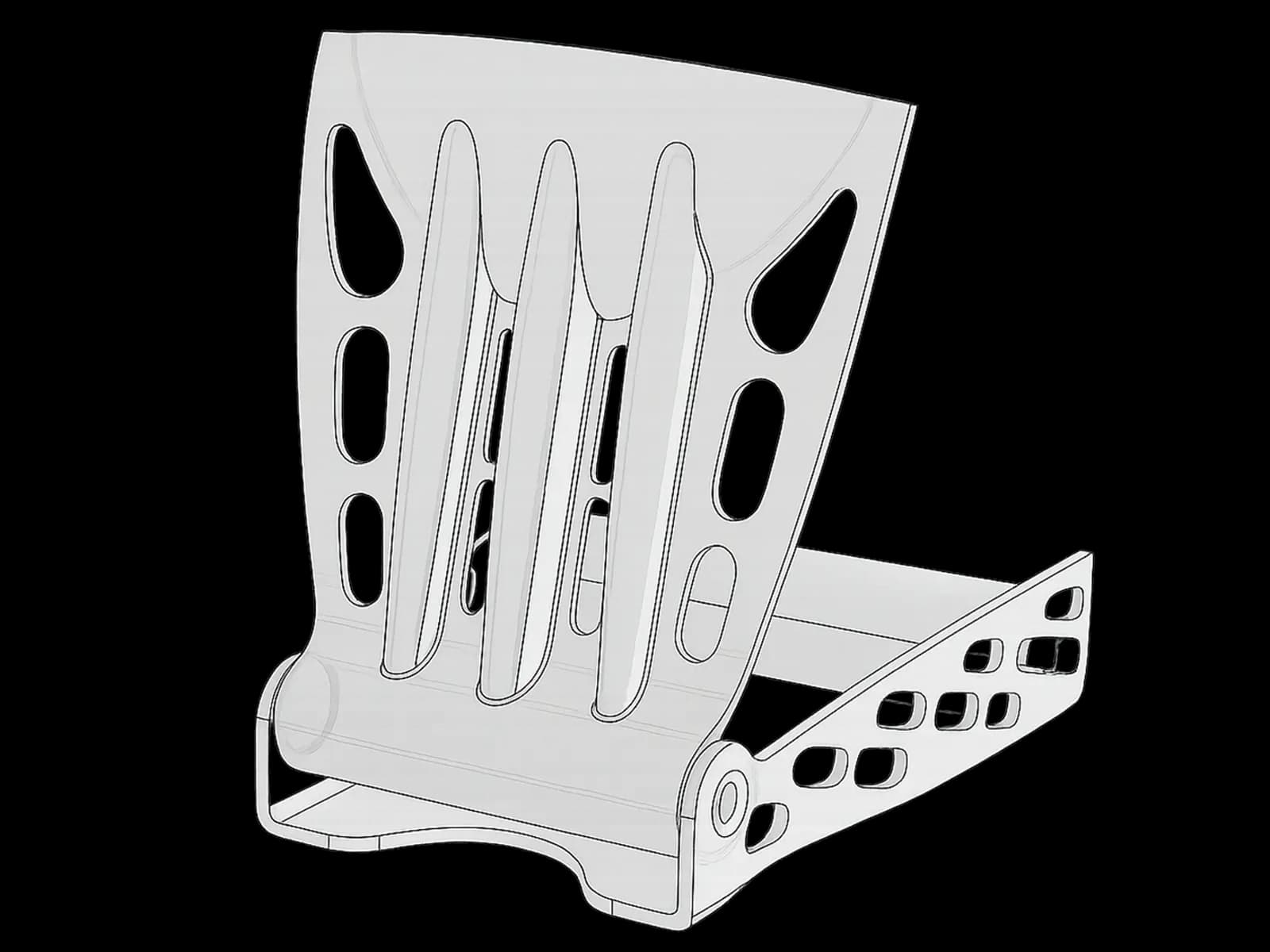

Steam runs extensive DFM analysis across SLS, MJF, DMLS, SLA, and FDM before an order can be placed. Manufacturing engineers annotate orientation-ready reports so technicians know the optimal build strategy before powder is loaded.

Closed-loop MES built in-house

We developed Steam to control quoting, scheduling, production cells, and logistics end to end. There are no external vendors or drop shipments; the same digital plan that priced your part guides execution on the floor.

Process documentation on autopilot

Batch control, build parameters, technician notes, and inspection approvals are captured automatically. Every shipment leaves with the manufacturing records regulated teams require without delaying production.

How every part moves through Steam

Our digital system follows each part from intake through release. Every stage is recorded, reviewed, and fed back into Steam so repeat runs stay consistent and compliant.

Upload raw CAD

Upload raw CADSecure intake keeps native STEP, STL, and 3MF files version-controlled inside Steam.

How Forge Labs delivers production-grade parts

Quality in additive manufacturing comes from controlling three things: where parts are made, how they're monitored, and what records follow them. We built Forge Labs Steam to integrate all three so industrial 3D printing delivers the consistency production programs require.

Production In-House

We control every additive manufacturing process in house, with no external vendors and no drop shipping. Polymer and metal production cells stay under our roof so quality decisions happen beside the machines, not across time zones or disconnected facilities.

The person taking your order is the same engineer inspecting your parts before they ship, ensuring accountability from the first quote to the final seal on the crate. When adjustments are needed, they happen in real time without waiting for external approvals or scheduling delays.

Polymer and metal AM, including SLS, MJF, DMLS, SLA, and FDM, run inside Forge Labs production cells, giving us direct control over machines, material conditioning, and scheduling.

Our engineering-led team manages every stage; the person you collaborate with on quoting is the same person certifying the parts that ship.

Steam captures every revision, deviation, and customer note so adjustments are implemented immediately without losing traceability or adding downtime.

Direct oversight eliminates the coordination overhead that slows production programs and introduces quality variability across suppliers.

Proprietary monitoring prevents issues before they start

Every machine on the floor is connected to Forge Labs Steam. Real-time telemetry and technician feedback produce automated reports that surface trends and catch potential issues before a build is at risk.

Laser power, temperature, and chamber data streamed into Steam

Automated alerts highlight drift before quality is impacted

Shift reports and photographs logged against each batch in real time

Insights loop directly back into build preparation and scheduling so repeat programs maintain the same high quality part after part.

Manufacturing documentation captured automatically

Steam maintains batch control and detailed manufacturing information automatically, giving your team instant access to the data needed for regulated industries and production handoffs. Process parameters, build histories, and inspection approvals are captured without delaying production.

Teams working in medical, aerospace, and defense sectors can retrieve inspection summaries, FAIR/PPAP packages, and comprehensive build documentation through our secure customer portal at any time, ensuring compliance records are audit ready the moment parts ship.

Machine IDs, build parameters, operator sign-offs, and finishing settings captured automatically for every shipment.

Part-level tracking across repeat production programs with revision history and change logs.

Technician notes, orientation data, dimensional checks, and quality approvals tied to each batch.

Documentation is generated as parts move through production, so regulated teams never chase paperwork or wait for quality releases.

Quality, speed, and economy without compromise

We combine industrial 3D printing technologies with our digital MES built for ISO 9001 quality systems to produce end-use parts that are ready for the production line, prototype lab, or field deployment.

Production ready additive manufacturing

Industrial 3D printing technologies deliver end-use parts with the repeatability global programs expect.

Accessible speed & economy

By unifying quoting through logistics, Steam keeps lead times tight and costs transparent without sacrificing compliance.

Documentation without chasing

Material certs, FAIR/PPAP packages, and build histories ensure the highest quality standards for additive MES.

Bring your next production program to Forge Labs Steam

Start with a manufacturability review or transition an existing program into our additive manufacturing cells for immediate capacity.