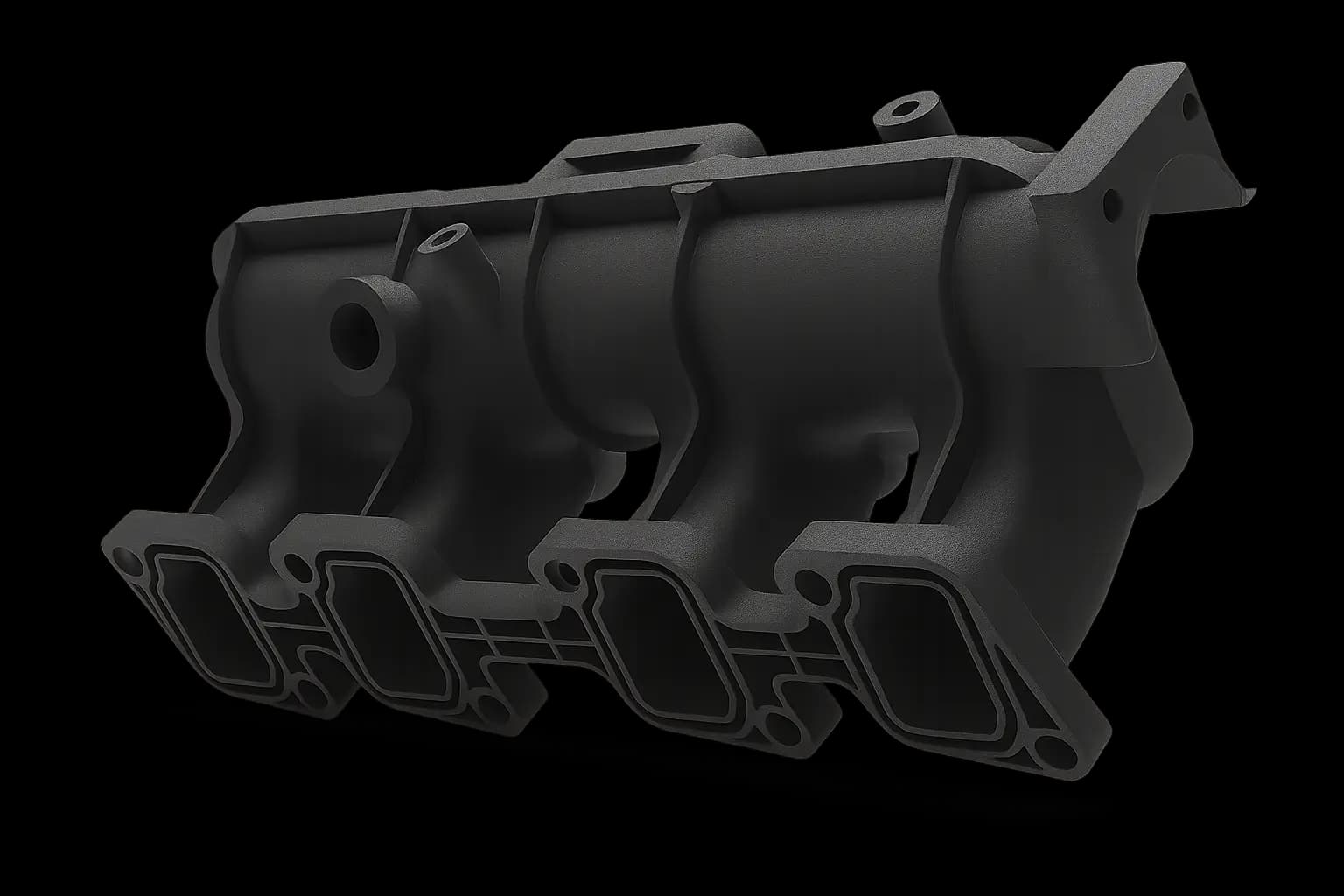

Glass-filled MJF PA12 delivers the strength-to-weight ratio crucial for aerospace applications. The material's enhanced stiffness and thermal stability enable structural brackets, mounting systems, and interior components that meet aviation requirements.

Key Applications

- Structural brackets and mounting hardware

- Avionics enclosures and housings

- Interior cabin components with flame retardancy

- UAV structural frames and components

Performance Data

Achieves 3200 MPa tensile modulus with only 1.22 g/cm³ density, providing aluminum-like stiffness at 60% the weight.