PolyJet MatrixMulti-Material High-Detail Prototyping & Design Validation

Revolutionary multi-material 3D printing technology that seamlessly integrates rigid, flexible, and transparent resins in a single build. Create prototypes with variable shore hardness, overmolds, and intricate assemblies with exceptional surface finish and fine detail resolution. Perfect for design validation, appearance models, and multi-material functional prototypes.

Technology Overview

Multi-Material Integration

PolyJet revolutionizes prototyping by seamlessly integrating multiple materials in a single build. Create complex assemblies with rigid housings, flexible gaskets, and transparent windows all printed simultaneously.

Advanced manufacturing capabilities enable complex geometries, functional prototypes, and end-use production parts that would be impossible or cost-prohibitive with traditional manufacturing methods. From functional prototypes to end-use production parts, this technology delivers exceptional performance across demanding industries.

Multi-Material Solutions

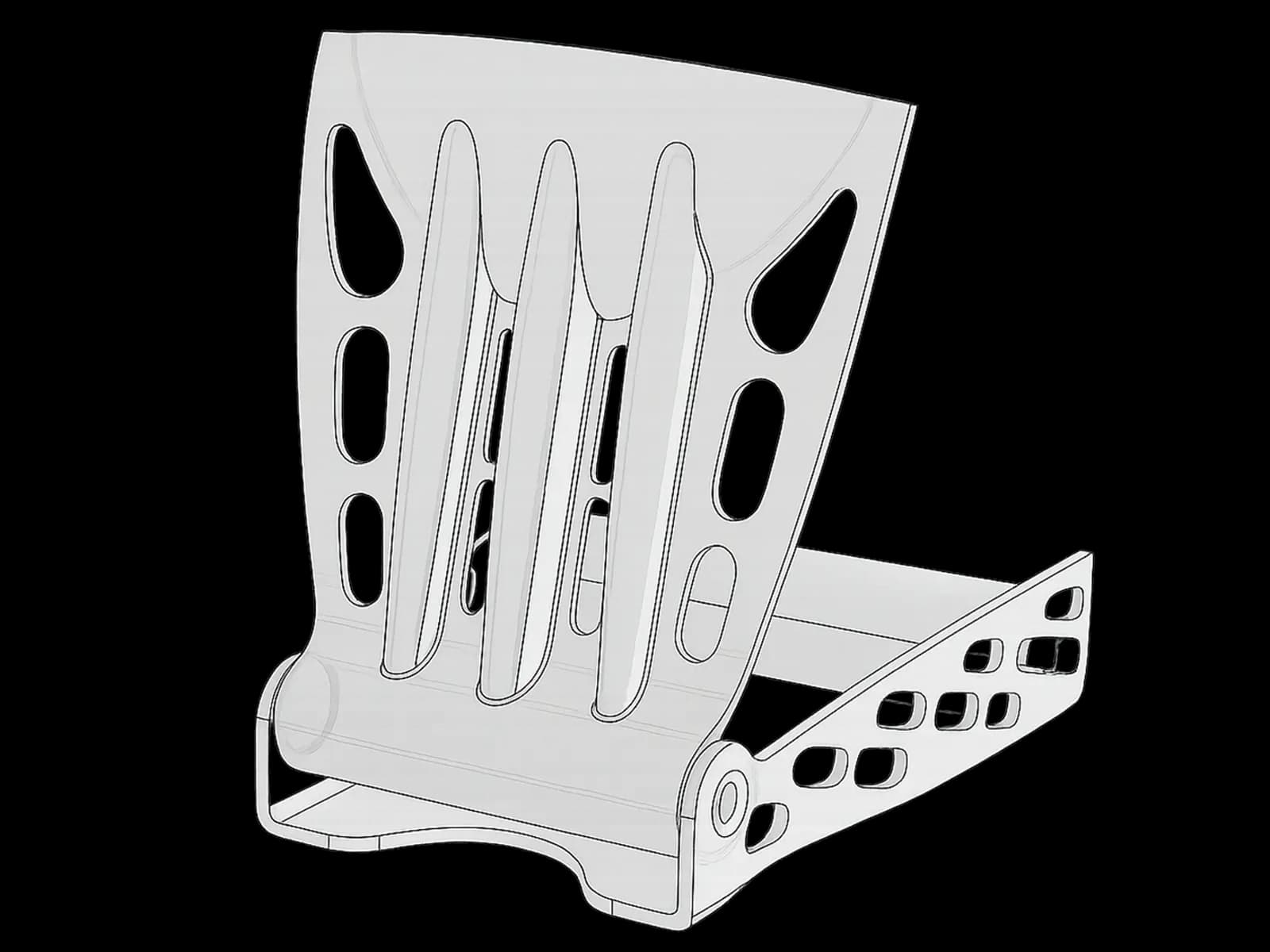

Multi-Material High-Detail Prototypes

Revolutionary multi-material technology that enables simultaneous printing of rigid, flexible, and transparent materials in a single build, creating complex assemblies with varying shore hardness and mechanical properties. From consumer electronics housings with integrated gaskets to medical devices with multiple material zones, PolyJet eliminates assembly steps while delivering exceptional surface quality and fine feature resolution for demanding applications.

Multi-Material Innovation

Design freedom reaches new levels with PolyJet's ability to create graduated material properties within single parts, enabling flexible hinges, soft-touch surfaces, and transparent windows integrated seamlessly. The UV-curing process produces parts with smooth surfaces requiring minimal post-processing, while water-soluble support materials enable complex internal geometries and delicate features. Color mixing capabilities create full-color prototypes and realistic product samples for marketing and user testing.

Key Advantages

Complex Geometries: Intricate internal channels, overhangs, and assemblies impossible with traditional manufacturing.

Functional Prototypes: Test mechanical properties and fit before investing in production tooling.

Custom Tooling: Jigs, fixtures, and manufacturing aids tailored to specific production requirements.

End-Use Parts: Production components for aerospace, medical, automotive, and industrial applications.

The PolyJet Matrix manufacturing process

PolyJet Matrix technology delivers unprecedented multi-material capabilities through precision inkjet deposition and instant UV curing, enabling complex assemblies with integrated soft and hard components in a single manufacturing step. Ultra-thin layers produce smooth, presentation-ready surfaces with fine feature detail. Gel-like support material is removed with water jetting, revealing multi-material parts ready for evaluation.

Multi-Material File Preparation

Multi-body STEP files are processed to identify different material regions. Each component is assigned specific material properties and print parameters for optimal quality.

Step Specifications

- Build Volume (mm)

- 380 × 284 × 380

- Tolerance

- ±0.2

- Layer Height (μm)

- 28

- Materials Available

- 3+

Multi-part trays with simultaneous rigid and flexible material builds.

Exceptional feature detail and smooth surfaces right off the printer.

Extremely thin layers for premium surface quality.

Rigid, rubber-like, transparent, and full-color photopolymers.

Multi-Material PolyJet Resins

Multi-material PolyJet resins enable complex assemblies with varying material properties in a single print. From rigid to flexible, transparent to opaque, our photopolymer selection supports diverse design requirements and functional prototypes.

RGD450 (Rigur)

Engineering Grade Material

Durable white rigid resin offering superior durability and impact resistance with polypropylene-like properties. Enhanced elongation and flexural strength for demanding prototyping applications.

Applications:

Agilus30 (TangoBlack)

Engineering Grade Material

Rubber-like material with superior elongation at break, tear resistance, and tensile strength. Can be blended with rigid materials to create custom shore hardness values from A30-A95.

Applications:

VeroClear

Engineering Grade Material

Highly rigid acrylic-based transparent material ideal for concept models and visual applications. Excellent detail visualization with dimensional stability and water resistance.

Applications:

Material Surface Finishes

PolyJet parts feature exceptional surface quality straight from the printer, with smooth finishes and fine detail resolution that often require minimal post-processing. The natural finish maintains intricate details while providing production-like aesthetics, making PolyJet ideal for design validation and presentation models.

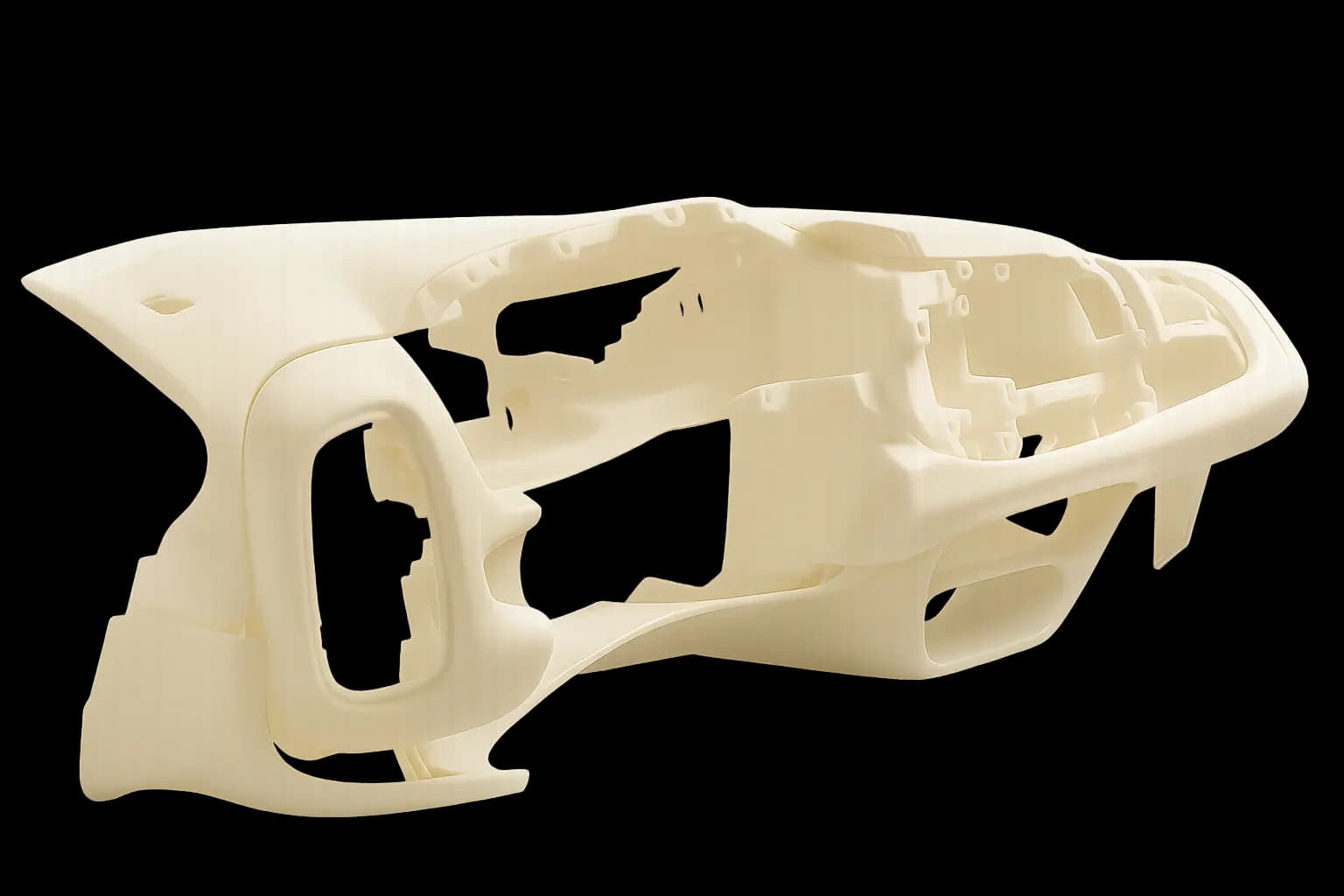

Natural Finish

As-Printed Surface Quality

PolyJet Matrix parts feature exceptional surface quality straight from the printer with minimal layer lines and smooth finish. The natural finish maintains fine detail resolution while providing a slightly off-white color with matte texture. This finish is ideal for functional testing and design validation without additional processing.

Finish Attributes

Performance Paint

Automotive-Grade Coating

Professional automotive-grade painting provides highly durable coating with custom color matching capabilities. Parts are hand-finished to high quality standards using professional coating equipment. Available in matte to semi-gloss finishes with precise color matching for branding requirements.

Finish Attributes

Additional Manufacturing Services

Maximize the potential of your PolyJet parts with our specialized design optimization and finishing services. From multi-material CAD preparation to professional color matching and assembly integration consulting.

Multi-Material Design Optimization

CAD optimization for multi-material printing and cost efficiency

Support Structure Optimization

Minimize support material usage and improve surface quality

Color Matching

Custom color development for brand-specific requirements

Assembly Integration

Design consultation for single-build multi-component assemblies

Surface Enhancement

Professional painting and finishing for presentation models

PolyJet Matrix Design Guidelines

Essential design considerations to optimize your PolyJet Matrix parts for manufacturing success.

Maximum Build Volume

380 × 284 × 380 mm (15 × 11.2 × 15 in)

Our Stratasys J750 DAP and Connex3 printers offer a maximum build volume of 380 × 284 × 380 mm (15 × 11.2 × 15 in), accommodating both small detailed components and larger assemblies. The system operates with a precise 28-micron layer height for exceptional detail resolution.

Multi-material builds require multi-body STEP files with separate bodies for each material assignment.

Tolerances

±0.2% (min ±0.2 mm)

PolyJet achieves dimensional accuracy with tolerances of ±0.2% (min ±0.2 mm). Parts with large flat surfaces may experience slight warping, so avoid these geometries when tight tolerances are critical.

Include engineering drawings for parts requiring specific tolerances.

Layer Height

28 Microns

The ultra-fine 28-micron layer height provides exceptional detail resolution and smooth surface finish. This precision enables fine features, sharp edges, and intricate geometries that would be difficult to achieve with other 3D printing technologies.

The fine layer height minimizes stepping artifacts on curved surfaces and angled features.

Surface Finish

Smooth, Ra 1-3 μm

PolyJet parts emerge with smooth, injection-molded quality surface finish straight from the printer. The combination of fine layer height and precise material deposition results in minimal post-processing requirements for most applications.

Gel-like support material removes cleanly without leaving marks on supported surfaces.

Advantages of PolyJet 3D Printing for Prototyping & Production

PolyJet empowers designers with unprecedented multi-material capabilities, enabling the creation of rubber-like prototypes with variable shore hardness, overmolds, soft-touch parts, and complex assemblies. This versatility combined with exceptional surface finish makes PolyJet ideal for creating highly aesthetic prototypes that accurately mimic injection-molded plastics and multi-material production parts.

- Multi-Material Integration

- Seamlessly combine rigid, flexible, and transparent materials in single builds for complex assemblies and overmolds.

- Variable Shore Hardness

- Create custom material properties from Shore A30 to A95 by blending flexible and rigid resins in precise ratios.

- Exceptional Detail Resolution

- Achieve intricate geometries and fine features with 28-micron layer height and smooth surface finish straight from the printer.

- Production-Like Aesthetics

- Parts emerge with injection-molded quality surface finish, ideal for design validation and customer presentations.

- Complex Geometry Freedom

- Print living hinges, snap-fits, and integrated assemblies without assembly requirements using soluble support material.

- Rapid Design Iteration

- Quick turnaround times enable fast design validation cycles with functional multi-material prototypes.

Instant Quote Tool

From Upload to Delivery

75% complete

Simple File Upload Process

Drag and drop your 3D files or browse to upload. Our system automatically analyzes your designs and provides instant feedback on printability and optimization suggestions.

- Drag & drop multiple file formats

- Automatic design analysis

- Printability feedback

- File optimization suggestions

PolyJet Applications Across Industries

Discover how PolyJet Matrix is transforming manufacturing across industries with innovative solutions and enhanced capabilities.

Multi-Material Prototypes

Complex assemblies with integrated soft and hard components, overmolds, and variable hardness regions in single prints

Medical & Anatomical Models

Realistic anatomical models with soft tissue simulation, surgical planning tools, and patient-specific medical devices

Consumer Product Development

High-fidelity prototypes for design validation, user testing, and investor presentations with production-like aesthetics

Automotive Interior Components

Soft-touch dashboard components, multi-material trim pieces, and functional prototypes with variable hardness

Success Stories

Real results from our PolyJet manufacturing partnerships

Multi-Material Wearable Device Housing

Consumer electronics prototype combining rigid housing with soft-touch user interface elements

Automotive Dashboard Prototype

Multi-material dashboard component with integrated soft-touch controls and rigid structural elements

Ready to manufacture your parts?

Upload your CAD files to get instant quotes for PolyJet 3D printing. Professional-grade manufacturing with fast turnaround times.

Click to start your quote

STL, STEP, OBJ, 3MF supported | Get instant pricing

PolyJet Questions & Answers

Common questions about PolyJet 3D printing technology. Can't find what you're looking for? Reach out to our technical team.