Accelerate Product Developmentwith Industrial 3D Printing

Forge Labs empowers industrial designers with fast, high-fidelity prototyping and functional parts—ready to test, refine, and launch. No tooling. No delays. Just real parts, fast. Industrial design 3D printing accelerates appearance models, user testing, and production-ready validation.

Industrial Design Excellence

Built for Designers Who Build Real Things

From concept mockups to fully functional prototypes, we support industrial design teams with additive manufacturing technologies that reduce lead times, eliminate tooling, and enable better design decisions—faster. Whether you're launching new hardware, building wearables, or testing injection-molded products, our process helps you move faster from sketch to shelf.

Transforming Industrial Design Manufacturing

From concept mockups to fully functional prototypes, we support industrial design teams with additive manufacturing technologies that reduce lead times, eliminate tooling, and enable better design decisions—faster. Whether you're launching new hardware, building wearables, or testing injection-molded products, our process helps you move faster from sketch to shelf.

Key Benefits of 3D Printing in Industrial Design

- Same-day or next-day prototype turnaround through advanced additive manufacturing solutions tailored for industrial design applications.

- Engineering guidance on material selection and DFM through advanced additive manufacturing solutions tailored for industrial design applications.

- High-detail visual and functional parts for testing through advanced additive manufacturing solutions tailored for industrial design applications.

- Eliminate expensive tooling requirements, reducing upfront investments and enabling economical low-volume production.

- Batch production available for pilot runs and market trials through advanced additive manufacturing solutions tailored for industrial design applications.

- CAD review, tolerance guidance, and design optimization through advanced additive manufacturing solutions tailored for industrial design applications.

Design for Manufacturing (DFM)

Comprehensive design optimization guidance ensuring prototypes translate effectively to production manufacturing processes.

Material Performance Validation

Rigorous testing protocols ensuring prototype materials accurately represent production behavior and performance characteristics.

Rapid Iteration Capability

Proven workflow enabling multiple design iterations within single development cycles, accelerating time-to-market for new products.

Scale-to-Production Support

Seamless transition from prototype to pilot production with volume manufacturing capabilities and production readiness validation.

Manufacturing Capabilities

Advanced Industrial Design Solutions

From precision prototyping to full-scale production, our comprehensive capabilities deliver results that transform industrial design manufacturing.

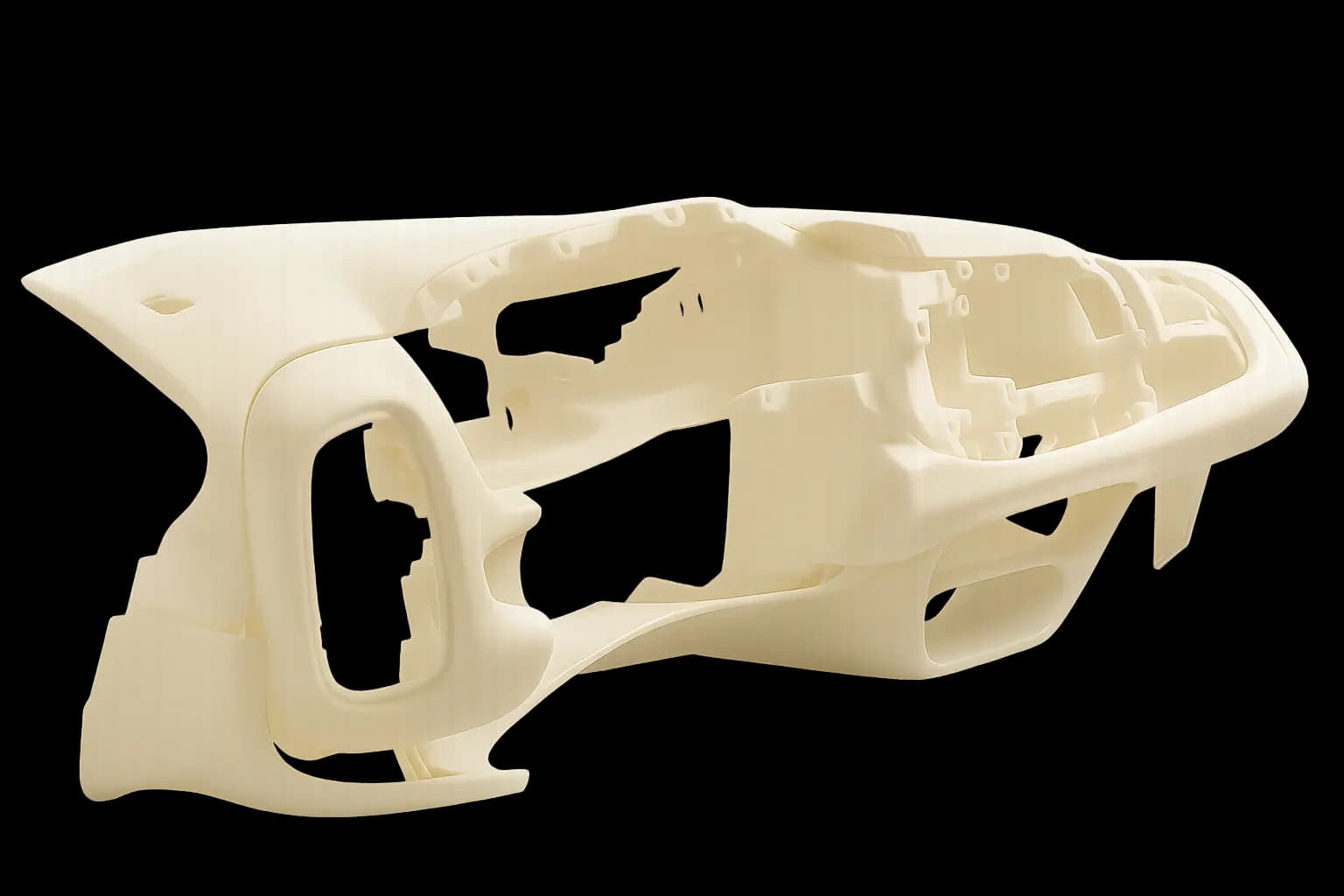

Selective laser sintering (SLS) with PA12 nylon delivers functional prototypes with mechanical properties closely matching injection-molded parts. Material characteristics include excellent impact resistance, chemical stability, and fatigue performance suitable for comprehensive testing protocols. Integrated features like snap-fits, living hinges, and threaded connections function as designed without assembly requirements. Dimensional accuracy of ±0.3% (min ±0.3 mm) supports tight-tolerance assemblies while surface quality enables direct testing without secondary finishing operations.

Functional Prototypes & Testing. Material: PA12 nylon SLS.

Technical Specifications

Stereolithography (SLA) with high-definition resins produces concept models with exceptional surface quality for color, material, and finish (CMF) validation studies. Multiple resin formulations simulate various material properties from rigid engineering plastics to flexible elastomers. Surface finish options include textured, polished, and painted applications with professional appearance suitable for client presentations and user research. Rapid turnaround enables multiple design iterations within single-day cycles supporting agile development methodologies.

Relevant Technologies

Design Iteration & CMF Studies. Surface Quality: High-definition.

Technical Specifications

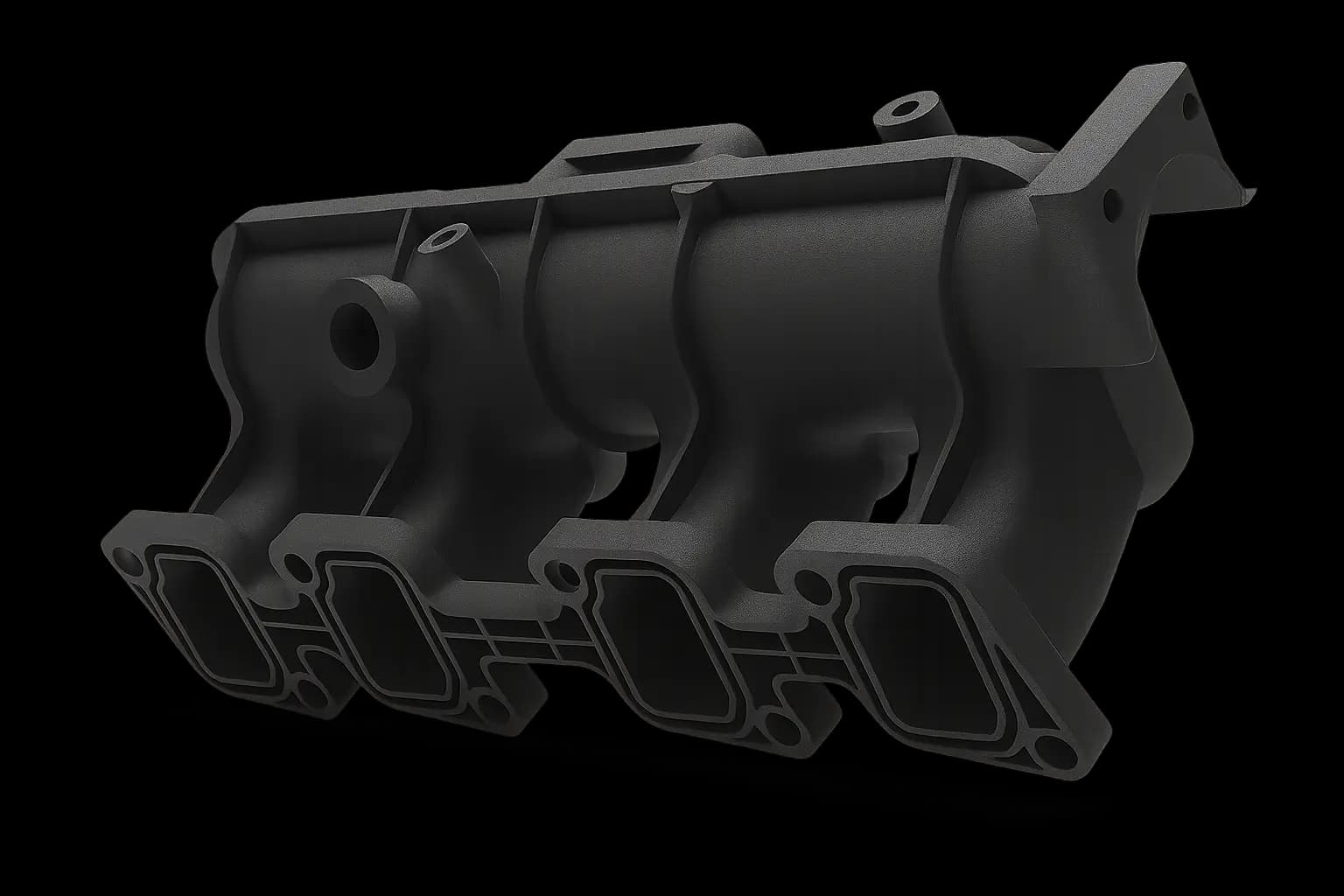

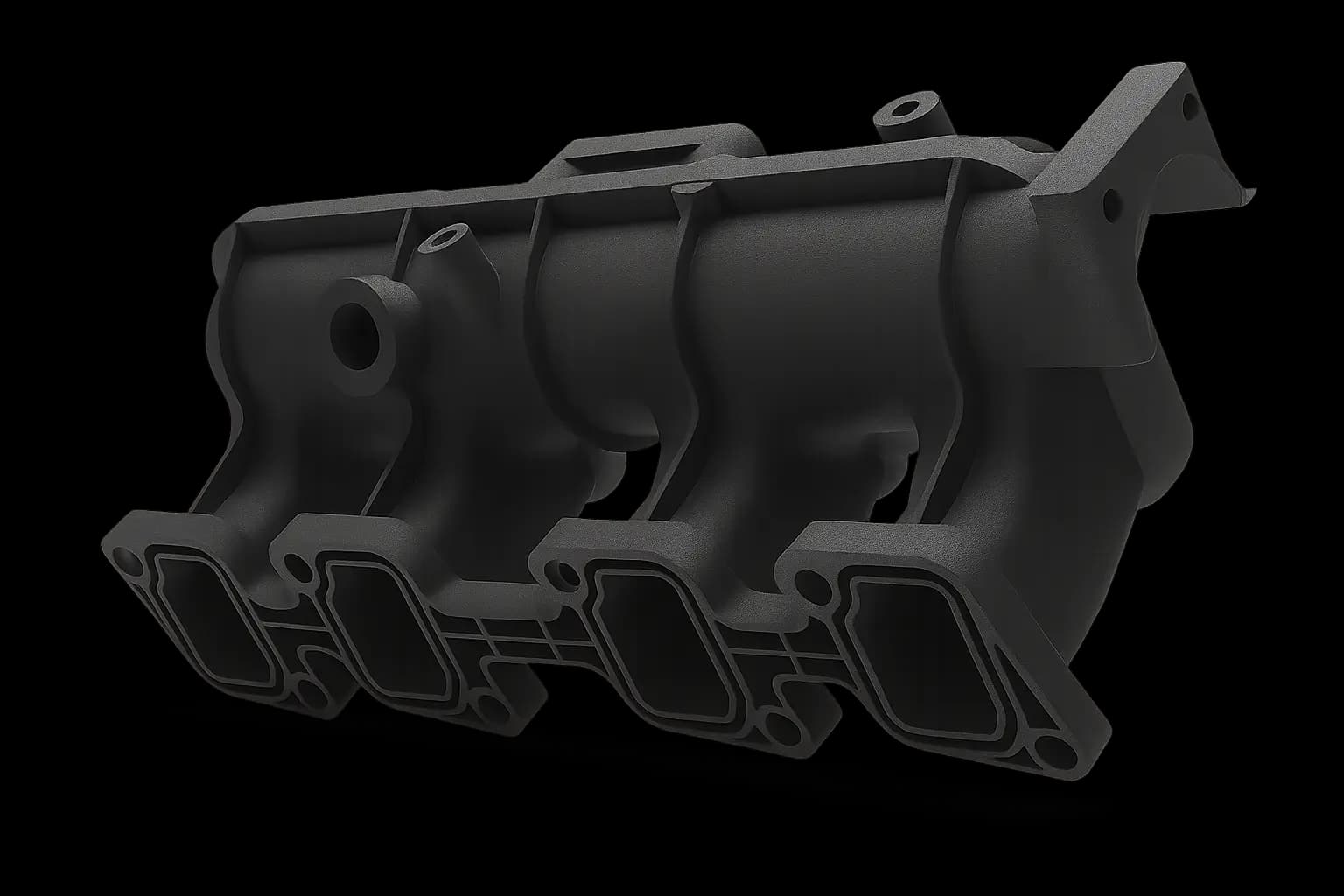

Multi Jet Fusion (MJF) technology produces mechanical assemblies with precise dimensional control and excellent surface finish for functional testing and validation. PA12 nylon material properties enable snap-fit mechanisms, threaded connections, and bearing surfaces that perform comparably to injection-molded components. Integrated assembly features eliminate secondary operations while maintaining clearances as tight as 0.5mm for moving parts. Heat-set insert compatibility and post-machining options provide production-ready fastening solutions for prototype assemblies.

Mechanical Parts & Assemblies. Technology: MJF PA12 nylon.

Technical Specifications

Fused deposition modeling (FDM) with maximum build volume (914 x 609 x 914mm) accommodates full-scale prototyping of outdoor gear, sports equipment, and mobility products. Engineering thermoplastics including carbon fiber reinforced nylon provide structural performance suitable for load testing and real-world validation. ASA materials offer UV stability and weather resistance for outdoor applications requiring extended environmental exposure. Large parts can be sectioned and assembled using integrated joinery features for products exceeding build volume constraints.

Relevant Technologies

Large Format Prototypes. Build Volume: 914 x 609 x 914mm.

Technical Specifications

Stereolithography (SLA) and selective laser sintering (SLS) technologies produce electronics housings with precise component fitment and professional surface finish. SLA tolerances of ±0.25% (min ±0.25 mm) ensure accurate PCB mounting, connector alignment, and button clearances critical for functional electronics assemblies. Material options include clear resins for LED diffusion, conductive formulations for EMI shielding, and flexible TPU for wearable interfaces. Integrated features like snap-fits, cable management, and heat-staking posts eliminate assembly complexity while maintaining professional appearance suitable for user testing and demonstration.

Consumer Electronics Housings. Component Fit: ±0.25% (min ±0.25 mm).

Technical Specifications

Digital manufacturing enables seamless scaling from prototype validation through pilot production volumes without tooling investment or long-term commitments. Multi Jet Fusion (MJF) and selective laser sintering (SLS) provide consistent part quality across production batches with statistical process control for dimensional verification. Batch sizes from 10 to 1,000+ units support market testing, investor demonstrations, and limited product launches. Quality documentation includes dimensional reports, material certificates, and batch traceability required for commercial validation and early-market feedback programs.

Market Testing & Pilot Production. Batch Sizes: 10-1,000+ units.

Technical Specifications

Case Studies

Success Stories

Real results from our industrial design partnerships

Outdoor Gear Development Program

Comprehensive prototyping program for North American outdoor gear brand, including snowboard binding components, bike frame assemblies, and field-ready equipment. Enabled rapid design iteration and real-world testing validation before production tooling investment.

Consumer Electronics Prototyping

Rapid prototyping of wearable device housings and consumer electronics for tech startup, including functional assemblies with integrated mounting features, button mechanisms, and display housings. Accelerated time-to-market for investor demos and user testing.

Certified Materials

Industrial Design-Grade Materials

High-performance materials engineered and certified for demanding industrial design applications with full traceability and compliance documentation.

Nylon PA12

Industrial Design grade

SLS nylon for functional prototypes

- Excellent mechanical properties

- Production-like behavior

- Ideal for mechanical parts

Accura ClearVue

Industrial Design grade

Crystal clear SLA resin

- Transparent design verification

- Smooth surface finish

- Excellent detail resolution

Glass Filled Nylon

Industrial Design grade

High-strength composite

- Lightweight structural applications

- Excellent for tooling

- Professional appearance

TPU 88A

Industrial Design grade

Flexible elastomer

- Soft-touch prototypes and gaskets

- Ideal for wearable components

- Sports gear interfaces

ABS

Industrial Design grade

Engineering thermoplastic

- Durable functional prototypes

- Impact resistant

- Easy post-processing

ASA

Industrial Design grade

UV-stable thermoplastic

- Outdoor and automotive applications

- Weather resistant

- Long-term durability

Explore Our Complete Material Matrix

Compare properties, applications, and certifications across our entire material portfolio. Filter by technology, industry, or specific requirements.

Manufacturing Technologies

Proven Technologies for Industrial Design

Each technology offers unique advantages for industrial design applications. Choose the right process for your specific requirements.

Selective Laser Sintering (SLS)

Stereolithography (SLA)

Fused Deposition Modeling (FDM)

Multi-Jet Fusion (MJF)

Not sure which technology is right for your project?

Our application engineers can help you select the optimal manufacturing process based on your specific requirements, materials, and timeline.

Ready to Transform Your Industrial Design Manufacturing?

Upload your CAD files for an instant quote or speak with our application engineers about your specific requirements.

Click to start your quote

STL, STEP, OBJ, 3MF supported | Get instant pricing