HP MJF PA12 delivers production-ready parts with the surface quality and mechanical properties required for automotive applications. The technology's speed and consistency enable just-in-time manufacturing of customized components and spare parts.

Key Applications

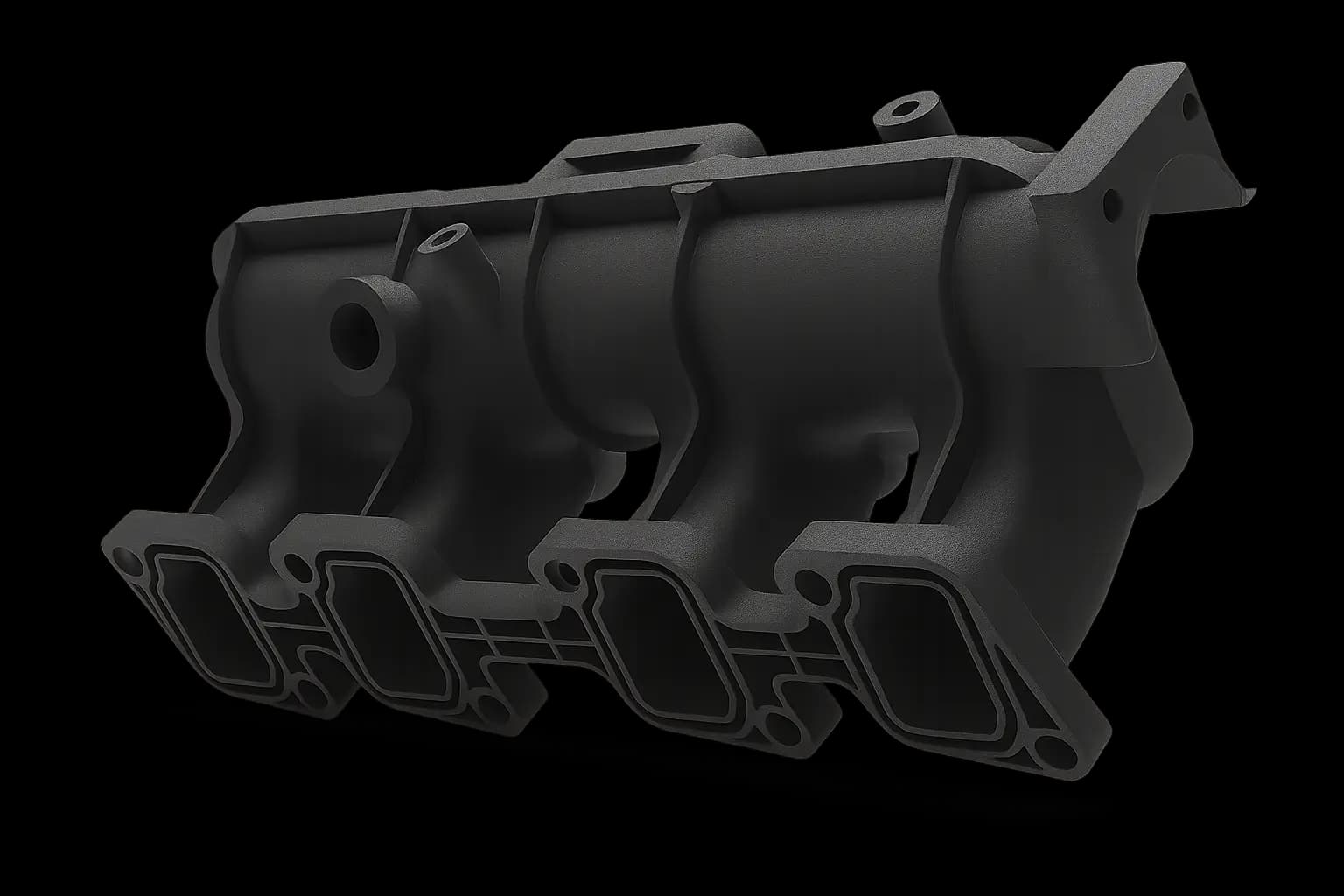

- Custom air intake systems and ducting

- Interior trim components and bezels

- Under-hood brackets and clips

- Personalized dashboard components

Performance Data

Achieves 48 MPa tensile strength with only 0.5% dimensional variance across builds, meeting automotive Cpk requirements for series production.