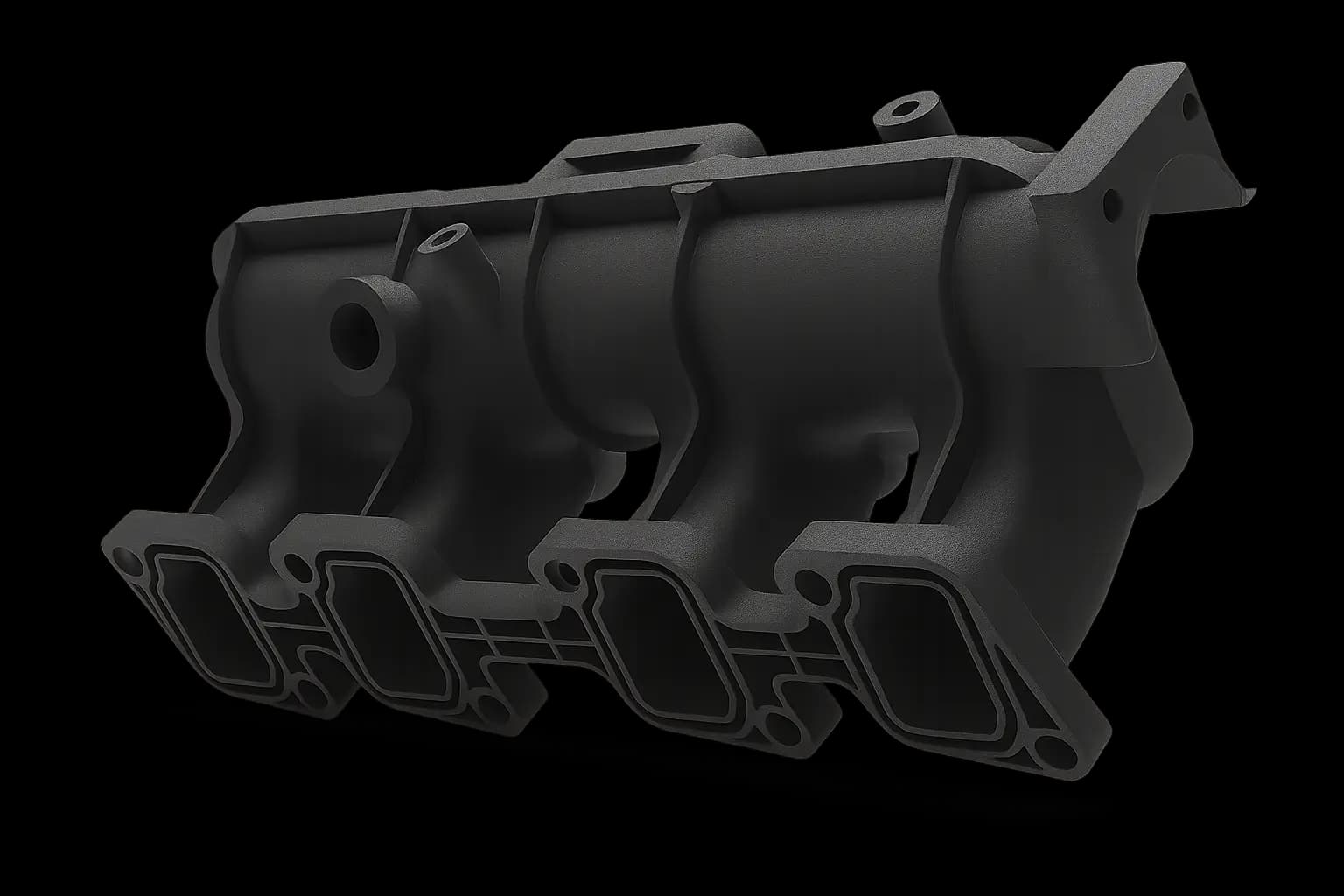

Nylon PA12 meets stringent aerospace requirements with its high strength-to-weight ratio and FAR 25.853 flame retardancy compliance. SLS processing eliminates support structures, enabling complex internal geometries for weight-optimized ducting and brackets.

Key Applications

- UAV components with 40% weight reduction

- Environmental control system ducting

- Cable management systems

- Vibration dampening mounts

Performance Data

Fatigue resistance up to 10^7 cycles at 22 MPa ensures reliability in cyclic loading conditions typical of flight operations.