Stereolithography3D Printing for High-Precision Parts and Prototypes

SLA produces parts with the finest detail and smoothest surface finish available in 3D printing, ideal for visual prototypes and precision applications. Common for masters, casting patterns, and high-detail prototypes that require a premium finish.

Technology Overview

Ultra-High Resolution Precision

SLA provides unmatched detail resolution and surface quality for applications demanding precision. From intricate prototypes to transparent optical components, SLA delivers glass-like finishes and dimensional accuracy.

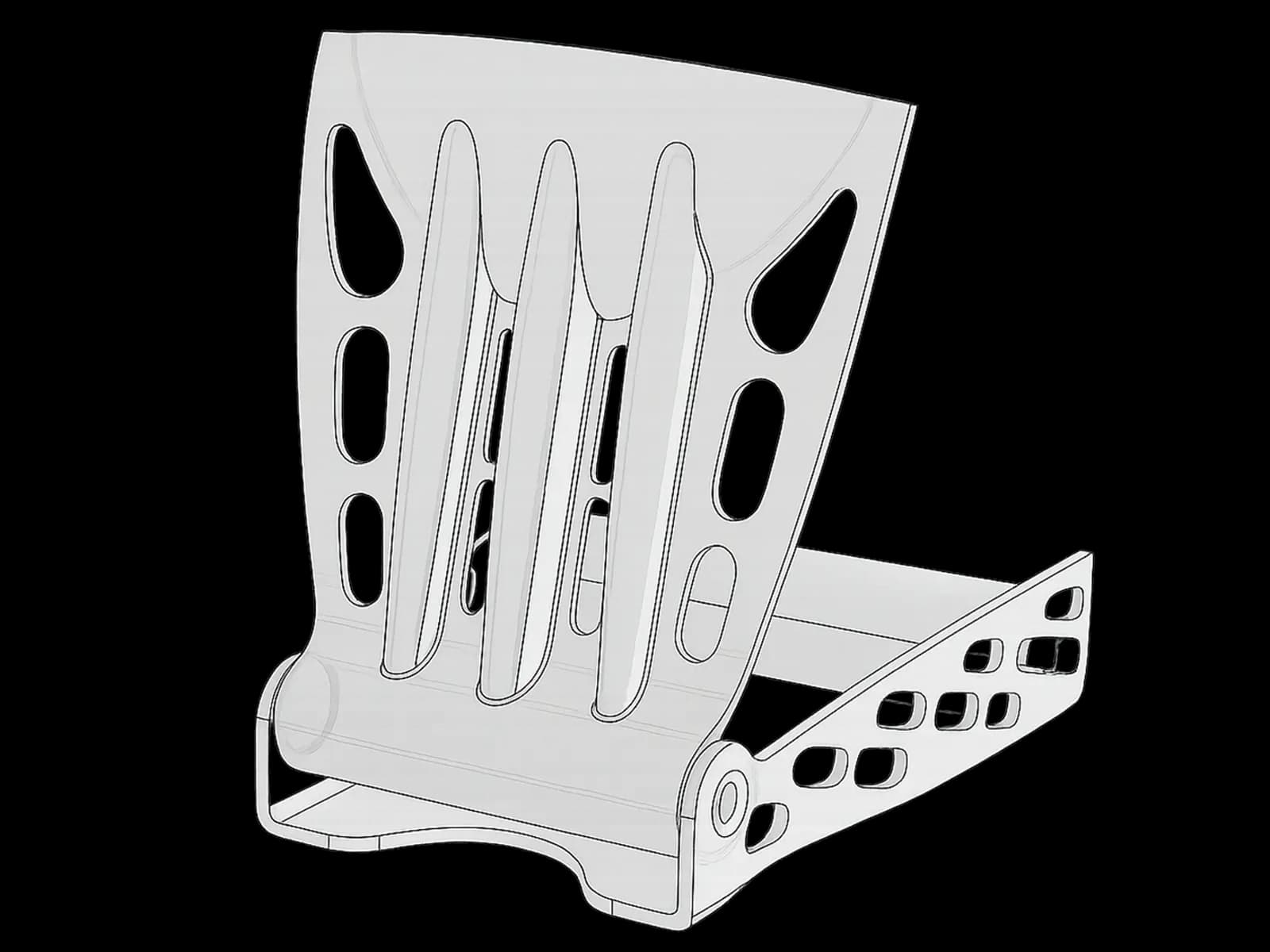

Advanced manufacturing capabilities enable complex geometries, functional prototypes, and end-use production parts that would be impossible or cost-prohibitive with traditional manufacturing methods. From functional prototypes to end-use production parts, this technology delivers exceptional performance across demanding industries.

Precision Prototyping

High-Detail Precision Prototypes

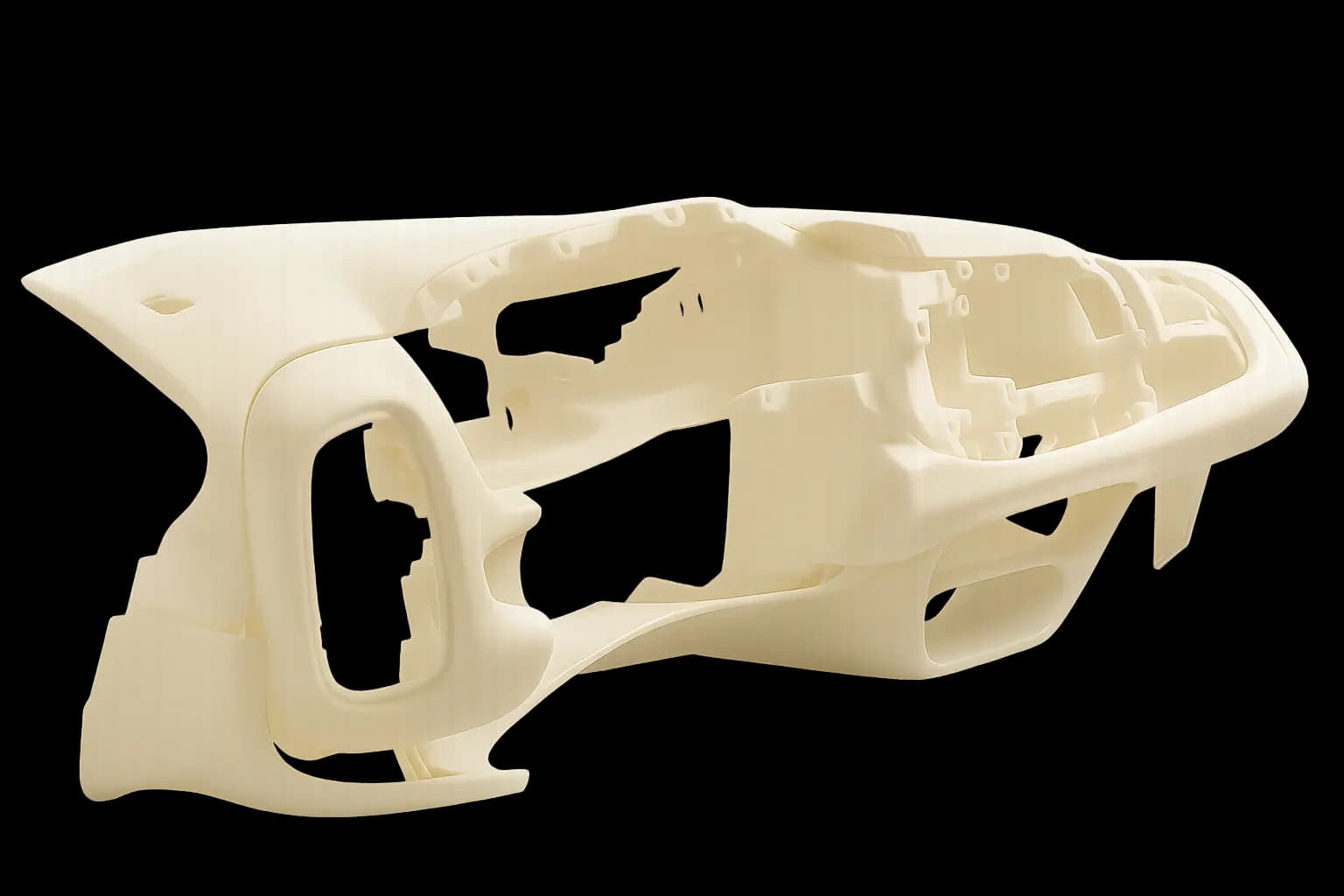

Essential for product development teams requiring exceptional surface finish and dimensional accuracy, SLA excels in detailed concept models, master patterns, and functional prototypes. The photopolymer curing process delivers smooth surfaces with minimal layer lines, making it ideal for visual prototypes, casting patterns, and intricate architectural models. With sub-millimeter precision and excellent feature resolution, SLA bridges the gap between initial design concepts and production-ready parts.

Precision Design Validation

Design teams leverage SLA for rapid iteration cycles, with parts ready for testing within hours of design completion. The liquid photopolymer process enables wall thicknesses as thin as 0.6mm and feature details down to 0.1mm, perfect for capturing intricate textures, fine text, and complex internal structures. Post-processing techniques like sanding, painting, and metal plating transform prototypes into presentation-ready models indistinguishable from final products.

Key Advantages

Complex Geometries: Intricate internal channels, overhangs, and assemblies impossible with traditional manufacturing.

Functional Prototypes: Test mechanical properties and fit before investing in production tooling.

Custom Tooling: Jigs, fixtures, and manufacturing aids tailored to specific production requirements.

End-Use Parts: Production components for aerospace, medical, automotive, and industrial applications.

High Detail SLA Resins

Precision SLA resins deliver exceptional detail resolution and smooth surface finishes. Our curated selection includes standard, tough, flexible, transparent, and biocompatible formulations for diverse prototyping and manufacturing applications.

Accura 25

ABS-Like Properties with Superior Detail

Accura 25 is a high-performance stereolithography resin engineered for exceptional detail, superior surface finish, and outstanding accuracy. With mechanical properties comparable to polypropylene, it offers a perfect balance of strength, flexibility, and impact resistance. This material excels in functional prototypes, snap-fit assemblies, and master patterns where precision and reliability are essential.

Applications:

Accura ClearVue

Glass-Like Transparency

Accura ClearVue delivers exceptional transparency with glass-like clarity, making it the ideal choice for applications requiring visual transparency. This versatile material simulates acrylic or glass properties while maintaining the precision and surface quality advantages of SLA technology. Perfect for optical prototypes, fluid visualization, and design validation where transparency is critical.

Applications:

Accura Xtreme White 200

Ultra-Tough Impact Resistance

Accura Xtreme White 200 is an ultra-tough white photopolymer specifically designed to replace CNC-machined polypropylene and ABS parts. This material offers exceptional impact resistance, outstanding durability, and superior snap-fit performance. With injection-molded surface quality and break-resistance, it's ideal for demanding functional applications including gaming controllers, automotive dashboards, and consumer electronics.

Applications:

High Temperature Resin

Industry-Leading Heat Resistance (238°C)

High Temperature Resin represents the pinnacle of thermal performance in stereolithography materials, offering an industry-leading heat deflection temperature of 238°C @ 0.45 MPa. This advanced photopolymer is specifically formulated for applications requiring exceptional thermal stability, enabling precise, detailed parts that maintain dimensional accuracy under extreme heat conditions. Perfect for automotive, aerospace, and industrial applications where conventional materials fail.

Applications:

USP Class VI Biocompatible ClearVue

USP Class VI Biocompatible Certification

USP Class VI Biocompatible ClearVue combines the exceptional optical properties of standard ClearVue with rigorous biocompatibility certification for medical applications. This material undergoes specialized 5-cycle cleaning protocols, enhanced material traceability, and comprehensive quality control to meet strict medical device manufacturing standards. Each batch includes full certification documentation, making it ideal for medical device prototypes and biomedical research applications.

Applications:

Stereolithography Design Guidelines

Essential design considerations to optimize your Stereolithography parts for manufacturing success.

Maximum Build Volume

1500mm x 750mm x 550mm (59" x 30" x 22")

SLA offers the largest build volume in our facility, capable of producing parts up to 59 inches long in a single build. Parts larger than this can be printed in sections and assembled.

This is one of the largest SLA build volumes available for industrial applications.

Tolerances

Standard parts: ±0.25%, Large parts: ±0.4%

Standard parts (10" x 10" x 10" or smaller): ±0.25%, with a lower limit of ±0.25 mm. Large parts (10" x 10" x 10" or larger): ±0.4%, with a lower limit of ±0.5 mm.

Tolerances as tight as +/- 0.2 mm (+/-0.005") can be achieved on request. If tighter tolerances are required, please provide an engineering drawing when requesting a quote.

Layer Height

50 or 100 microns

Parts are printed at the standard 100 micron layer thickness (HD) unless our high definition (XHD) option is chosen, at 50 microns. Keep in mind that our higher resolution option also doubles the print time.

Higher resolution (50 micron) layers significantly increase print time but provide superior detail resolution.

Surface Finish

High Definition

Parts have a smooth and uniform surface finish. Very small layer lines may still be visible, especially on surfaces at a low angle relative to the build plate.

SLA provides the smoothest surface finish among all additive manufacturing technologies.

Advantages of SLA 3D Printing for Prototyping & Production

Stereolithography offers unique advantages for modern manufacturing applications, delivering exceptional performance and versatility for both prototyping and production requirements. Key benefits include cost-effective manufacturing, superior material properties, and the ability to produce complex geometries that would be impossible or expensive with traditional manufacturing methods.

- Highest Detail

- Unmatched resolution and surface quality for precision applications

- Smooth Finish

- Glass-like surface finish requiring minimal post-processing

- Material Variety

- Wide range of material properties from flexible to rigid, clear to opaque

- Precision Accuracy

- Exceptional dimensional accuracy for tight-tolerance applications

Instant Quote Tool

From Upload to Delivery

75% complete

Simple File Upload Process

Drag and drop your 3D files or browse to upload. Our system automatically analyzes your designs and provides instant feedback on printability and optimization suggestions.

- Drag & drop multiple file formats

- Automatic design analysis

- Printability feedback

- File optimization suggestions

SLA Applications Across Industries

Discover how Stereolithography is transforming manufacturing across industries with innovative solutions and enhanced capabilities.

Visual Prototypes

High-quality appearance models for design validation

Jewelry & Detailed Parts

Intricate jewelry patterns, miniatures, and fine-detailed components requiring exceptional resolution

Medical & Dental Models

Accurate anatomical models, surgical guides, and dental applications requiring biocompatible materials

Optical Components

Transparent lenses, light guides, and optical prototypes with exceptional clarity and precision

Detailed Gaming Components

Highly detailed gaming controllers, figurines, and artistic models with intricate surface features

Success Stories

Real results from our SLA manufacturing partnerships

Rapid Prototyping for Tim Hortons Lid Redesign

High-precision SLA prototypes enabled rapid iteration and validation of new lid design with superior surface finish for functional testing

Precision Automotive Component Prototyping

SLA's exceptional detail resolution and smooth surface finish enabled accurate validation of complex automotive interior components

Ready to manufacture your parts?

Upload your CAD files to get instant quotes for SLA 3D printing. Professional-grade manufacturing with fast turnaround times.

Click to start your quote

STL, STEP, OBJ, 3MF supported | Get instant pricing

SLA Questions & Answers

Common questions about SLA 3D printing technology. Can't find what you're looking for? Reach out to our technical team.