ULTEM 1010's ability to withstand 180°C autoclave cycles makes it the premier choice for composite tooling. The material maintains dimensional stability through repeated cure cycles, enabling cost-effective tooling for aerospace composites.

Key Applications

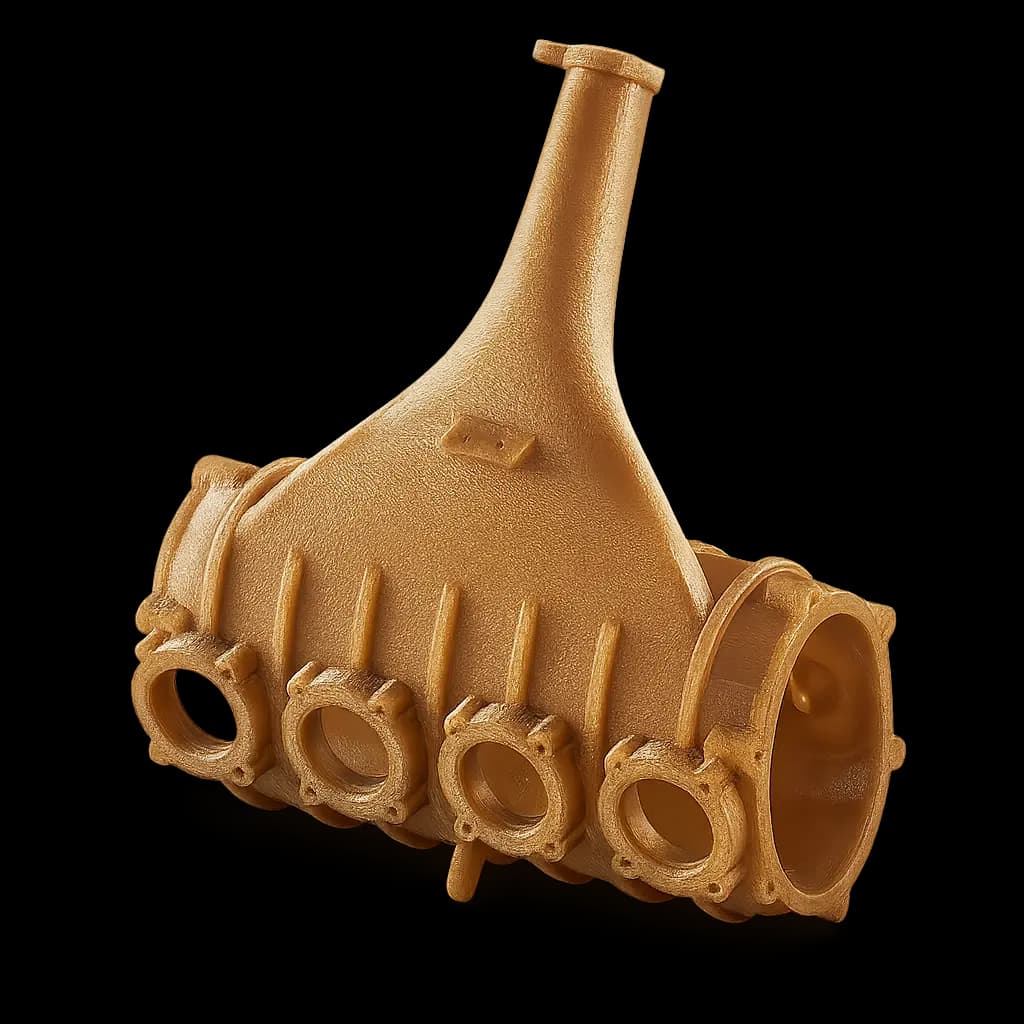

- Autoclave-capable composite lay-up tools

- Vacuum bagging mandrels and caul plates

- Trim and drill fixtures for cured composites

- Bonding jigs for aerospace assemblies

Performance Data

Maintains ±0.2% dimensional accuracy through 50+ autoclave cycles at 180°C/100 psi, with <0.5% moisture absorption preventing tool degradation.