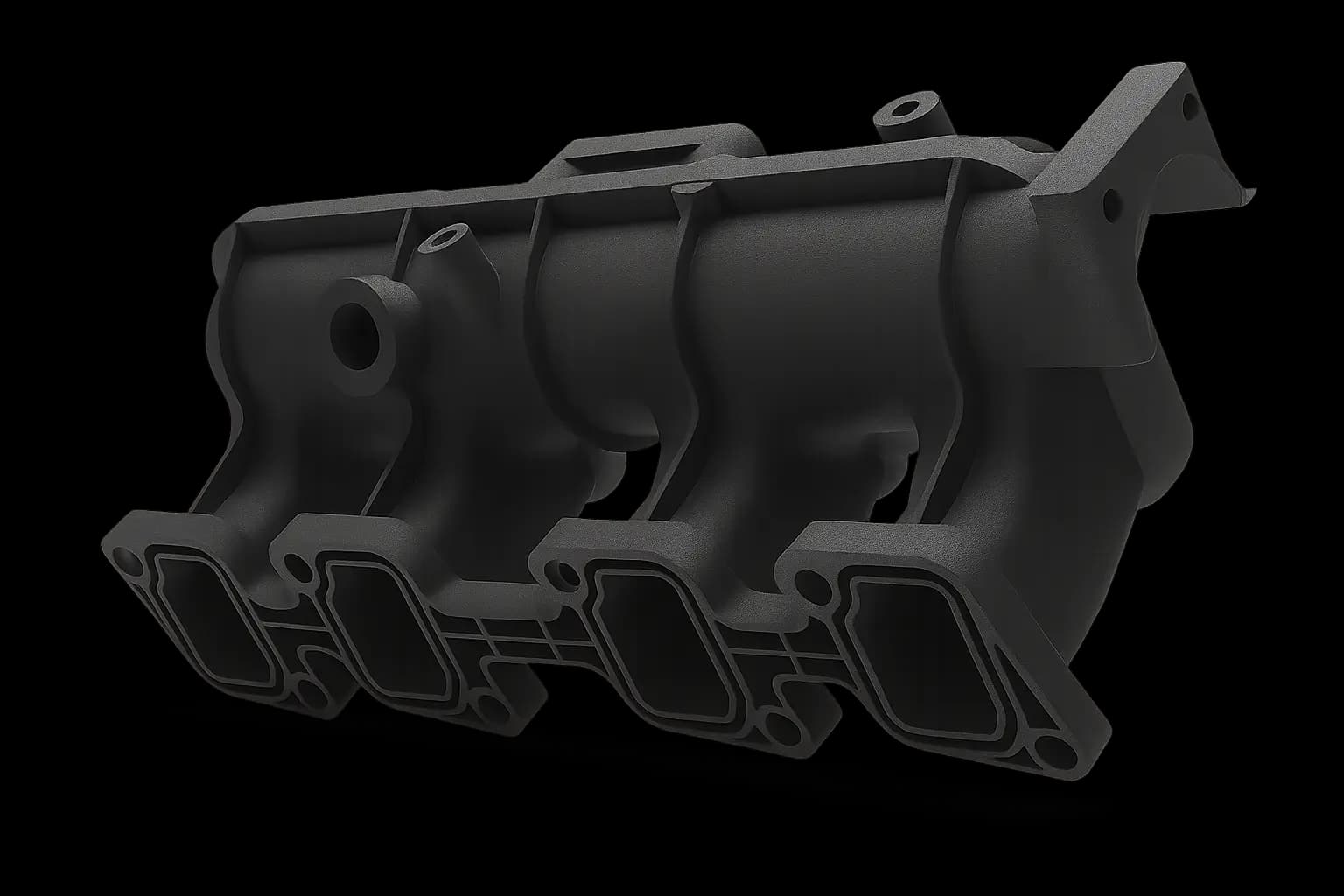

Glass Filled PA12 meets automotive requirements for stiffness, heat resistance, and dimensional stability. The material survives under-hood temperatures while maintaining tight tolerances for assemblies.

Key Applications

- Intake manifolds and air ducts

- Engine covers and shrouds

- Bracket systems and mounts

- Sensor housings and connectors

Performance Data

Maintains dimensional stability <0.3% after 1000 hours at 80°C with 30% higher stiffness than standard PA12.