Fused Deposition Modeling3D Printing for Functional Prototypes & Large Parts

Industry-leading precision with best-in-class repeatability and layer adhesion. Manufacture using industrial-grade thermoplastics like ABS, ASA, PC, and ULTEM up to 36" × 24" × 36". Ideal for large-format prototypes, jigs, fixtures, and durable end-use components.

Technology Overview

Industrial-Grade Large Format 3D Printing

Industrial FDM systems deliver large-format capabilities with engineering-grade thermoplastics. From aerospace components to automotive tooling, FDM provides reliable, cost-effective manufacturing for demanding applications.

Advanced manufacturing capabilities enable complex geometries, functional prototypes, and end-use production parts that would be impossible or cost-prohibitive with traditional manufacturing methods. From functional prototypes to end-use production parts, this technology delivers exceptional performance across demanding industries.

Industrial Manufacturing

High Performance FDM Thermoplastics

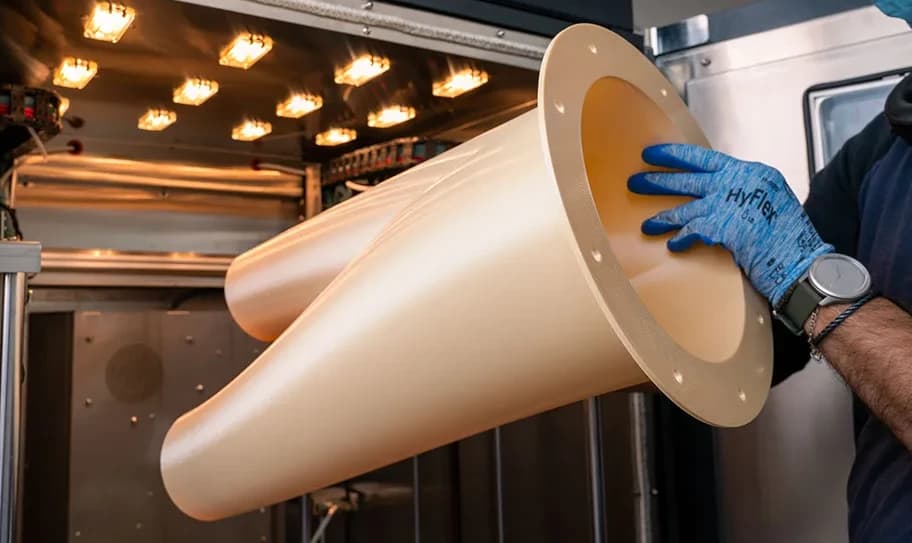

Trusted by manufacturers for large-scale production and industrial applications, FDM technology enables cost-effective manufacturing of oversized parts and complex assemblies. Engineering-grade thermoplastics like ULTEM, PEEK, and carbon fiber composites provide exceptional strength-to-weight ratios and chemical resistance. From aerospace ducting to automotive tooling, FDM offers unmatched scalability for both prototyping and end-use manufacturing with minimal material waste.

Manufactured for Demanding Applications

Manufacturing environments demand reliable, repeatable processes that FDM consistently delivers through heated chamber technology and precise material deposition. Large build volumes accommodate parts up to 900mm, while multi-axis capabilities enable complex overhangs and internal structures. The heated chamber ensures dimensional stability in engineering thermoplastics, critical for jigs, fixtures, and end-use components in demanding industrial applications.

Key Advantages

Complex Geometries: Intricate internal channels, overhangs, and assemblies impossible with traditional manufacturing.

Functional Prototypes: Test mechanical properties and fit before investing in production tooling.

Custom Tooling: Jigs, fixtures, and manufacturing aids tailored to specific production requirements.

End-Use Parts: Production components for aerospace, medical, automotive, and industrial applications.

The Fused Deposition Modeling (FDM) manufacturing process

Fused Deposition Modeling uses industrial Stratasys 3D printers with heated extruders and enclosed build chambers to melt and deposit thermoplastic filament layer by layer, creating strong, durable parts with excellent material properties. Controlled chamber heat minimizes warping on large parts and improves layer adhesion in engineering thermoplastics. Support material is removed after printing, leaving parts ready for post-processing.

Material Loading & Preparation

Industrial-grade thermoplastic filament is loaded into the heated extruder system. The enclosed build chamber is preheated to optimal temperature to prevent warping and ensure consistent layer adhesion.

Step Specifications

- Build Volume (mm)

- 914 × 609 × 914

- Tolerance

- ±0.25 mm or ±0.3, whichever is greater

- Layer Height (μm)

- 127

- Materials Available

- 7+

Large format builds for oversized parts and fixtures in one piece.

Reliable dimensional control for jigs, fixtures, and functional prototypes.

Tuned for speed vs. finish; thicker layers for throughput, thinner for detail.

ULTEM, PEEK, ABS, ASA, and carbon-fiber composites for engineering use.

High Performance FDM Thermoplastics

Professional-grade FDM thermoplastics engineered for strength, precision, and reliability. From standard engineering plastics to high-performance PEEK and carbon fiber composites, our material library covers applications from prototyping to end-use manufacturing.

ABS

Engineering Grade Material

The strongest ABS plastic - up to 70% stronger than standard ABS with superior layer bonding and impact resistance

Applications:

ABS-ESD7

Electrostatic Dissipative Properties

Static dissipative ABS thermoplastic ideal for applications where static charge can damage products or cause explosions

Applications:

ASA

Engineering Grade Material

UV-stable thermoplastic with excellent weather resistance and strong mechanical properties

Applications:

Polycarbonate (PC)

Engineering Grade Material

Exceptionally high tensile and flexural strength thermoplastic for demanding applications

Applications:

PC-ABS

Engineering Grade Material

Combines PC strength and heat resistance with ABS flexibility and cost advantages

Applications:

ULTEM 9085

Engineering Grade Material

High-performance polyetherimide with excellent strength-to-weight ratio and FST ratings

Applications:

ULTEM 1010

Engineering Grade Material

Highest tensile strength, heat and chemical resistance of any additive thermoplastic

Applications:

Material Surface Finishes

FDM parts have a distinct layer-by-layer texture with visible striations, resulting in a slightly rough, ribbed surface finish. While the natural finish is durable and functional for most applications, post-processing techniques can significantly enhance appearance and performance. Vapor smoothing chemically melts the outer surface, creating a glossy, sealed finish with improved strength. Performance painting provides a professional, polished look with custom color matching capabilities.

Standard Finish

Visible Layer-by-Layer Texture

FDM 3D printed parts have a visible layer-by-layer texture with slight ridges and striations, resulting in a rougher surface finish compared to other 3D printing technologies like SLS or SLA. Soluble supports are dissolved in an ultrasonic cleaning tank, while physical supports on high-temperature materials are removed by hand if required.

Finish Attributes

Vapor Smoothing

Chemically Smoothed Surface

Vapor smoothing dissolves the outer layer, causing it to smooth out and blend, reducing layer lines and enhancing the part's appearance. This process creates a glossy, sealed surface with improved strength, reduced porosity, and increased chemical resistance, making it ideal for functional and aesthetic applications.

Finish Attributes

Performance Paint

Automotive-Grade Coating

Painting offers a highly durable, automotive-grade coating that enhances the aesthetics and durability of 3D-printed parts. Each part is hand-finished to ensure smooth surfaces and a premium quality appearance. Using professional-grade coating equipment, this process allows for precise application and exceptional adhesion. Custom color matching is available, making it ideal for applications that require specific branding or visual impact.

Finish Attributes

Additional Manufacturing Services

Complete your FDM parts with our precision post-processing services for production-ready components with enhanced performance and aesthetics.

Threading

Precision threads for functional assemblies

Tapping

Drill press tapped holes for connections

Heat Set Inserts

Threaded inserts for durable fastening

Assembly Services

Professional part assembly & integration

CAD Optimization

Optimize parts for FDM production

Fused Deposition Modeling Design Guidelines

Essential design considerations to optimize your Fused Deposition Modeling parts for manufacturing success.

Maximum Build Volume

914mm x 609mm x 914mm (36" x 24" x 36")

FDM produces parts up to 36 inches in a single build. Parts larger than the build volume can be printed in sections and assembled.

This is one of the largest build volumes available for industrial FDM systems.

Tolerances

±0.25 mm or ±0.3%, whichever is greater

Industrial FDM achieves tolerances of ±0.25 mm or ±0.3%, whichever is greater. TPU 95A: ±0.3% (min ±0.15 mm). Tighter tolerances may be achievable depending on geometry and orientation.

Tighter tolerances may be achievable on request with engineering drawings.

Layer Height

127 - 330 microns

Standard layer height is 254 microns (0.010″) unless otherwise stated. Industrial FDM machines can print parts with custom layer thickness, in the range of 127 - 330 microns thick. Thicker layers typically result in better adhesion and better mechanical properties.

Thicker layers provide better strength but lower surface quality.

Surface Finish

Visible Layer Lines

Parts made with FDM will always show visible layer lines, especially on curved surfaces. However, the visibility of layer lines can be reduced with smaller layer heights at the expense of print speed.

Layer lines are inherent to the FDM process and cannot be completely eliminated.

Advantages of FDM 3D Printing for Prototyping & Production

Fused Deposition Modeling offers unique advantages for modern manufacturing applications, delivering exceptional performance and versatility for both prototyping and production requirements. Key benefits include cost-effective manufacturing, superior material properties, and the ability to produce complex geometries that would be impossible or expensive with traditional manufacturing methods.

- Large-Format Printing

- Capable of producing sizable parts in a single build, FDM is well-suited for applications requiring large prototypes, jigs, and fixtures

- Cost-Effective Manufacturing

- FDM is one of the most affordable 3D printing technologies, making it ideal for rapid prototyping and low-volume production

- Functional Prototyping

- Parts can be printed using industrial thermoplastics with properties close to injection-molded components

- Material Variety

- Compatible with a wide range of thermoplastics, including ABS, PC, high-performance ULTEM, and fiber-reinforced composites

- Strong Layer Adhesion

- Engineered for high-strength applications, FDM prints offer excellent interlayer bonding for durable, impact-resistant parts

- Scalable Production

- Adaptable for both single-part manufacturing and batch production while maintaining cost efficiency

- Mechanical Strength & Durability

- FDM parts exhibit excellent mechanical strength and impact resistance, ideal for tooling and functional components

Instant Quote Tool

From Upload to Delivery

75% complete

Simple File Upload Process

Drag and drop your 3D files or browse to upload. Our system automatically analyzes your designs and provides instant feedback on printability and optimization suggestions.

- Drag & drop multiple file formats

- Automatic design analysis

- Printability feedback

- File optimization suggestions

FDM Applications Across Industries

Discover how Fused Deposition Modeling is transforming manufacturing across industries with innovative solutions and enhanced capabilities.

Aerospace Components

Lightweight, strong parts for aircraft interiors, tooling, and UAV components with high-performance materials

Automotive Manufacturing

Functional prototypes, under-hood components, and production tooling with heat and chemical resistance

Medical Devices

Biocompatible parts for medical equipment, surgical guides, and custom prosthetics

Industrial Design

Functional prototypes, design validation, and low-volume production for product development

Success Stories

Real results from our FDM manufacturing partnerships

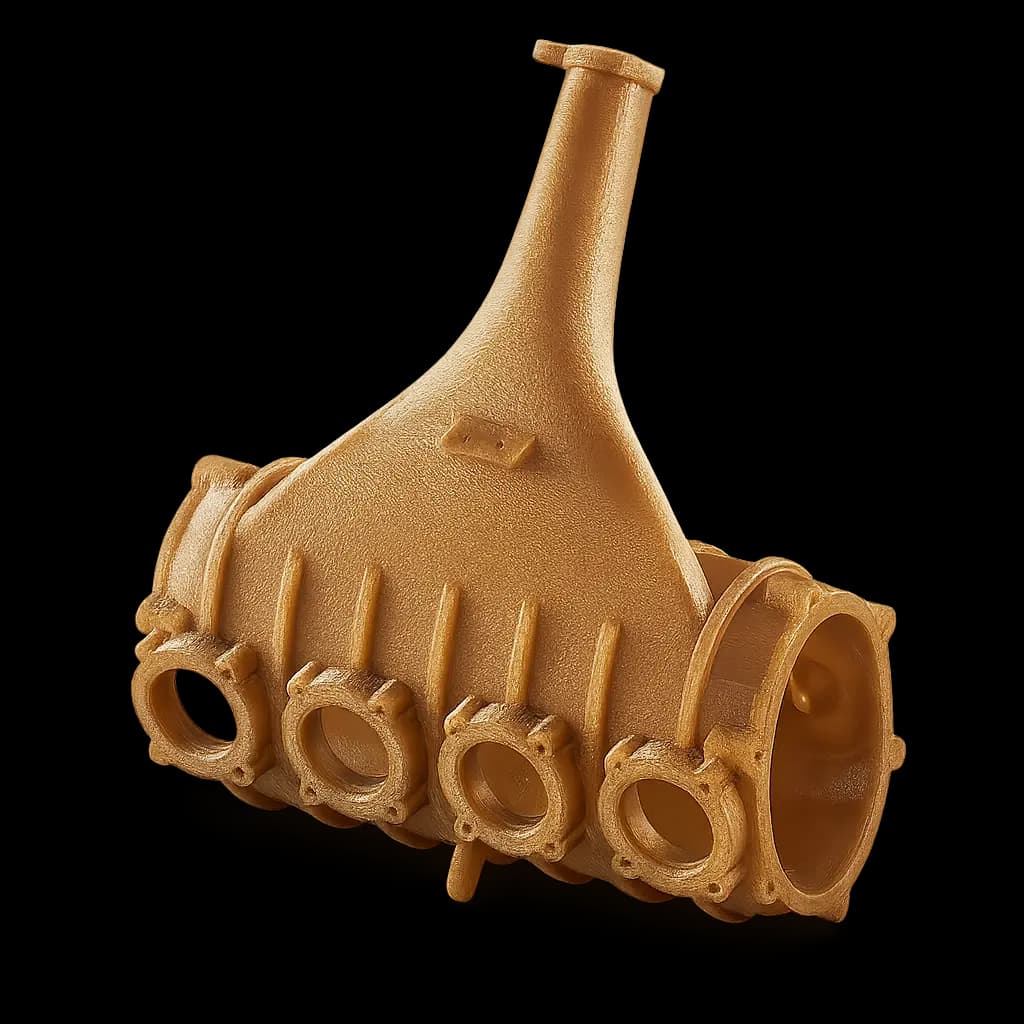

Aerospace Ducting System

Large-format ULTEM ducting components for commercial aircraft with integrated mounting features

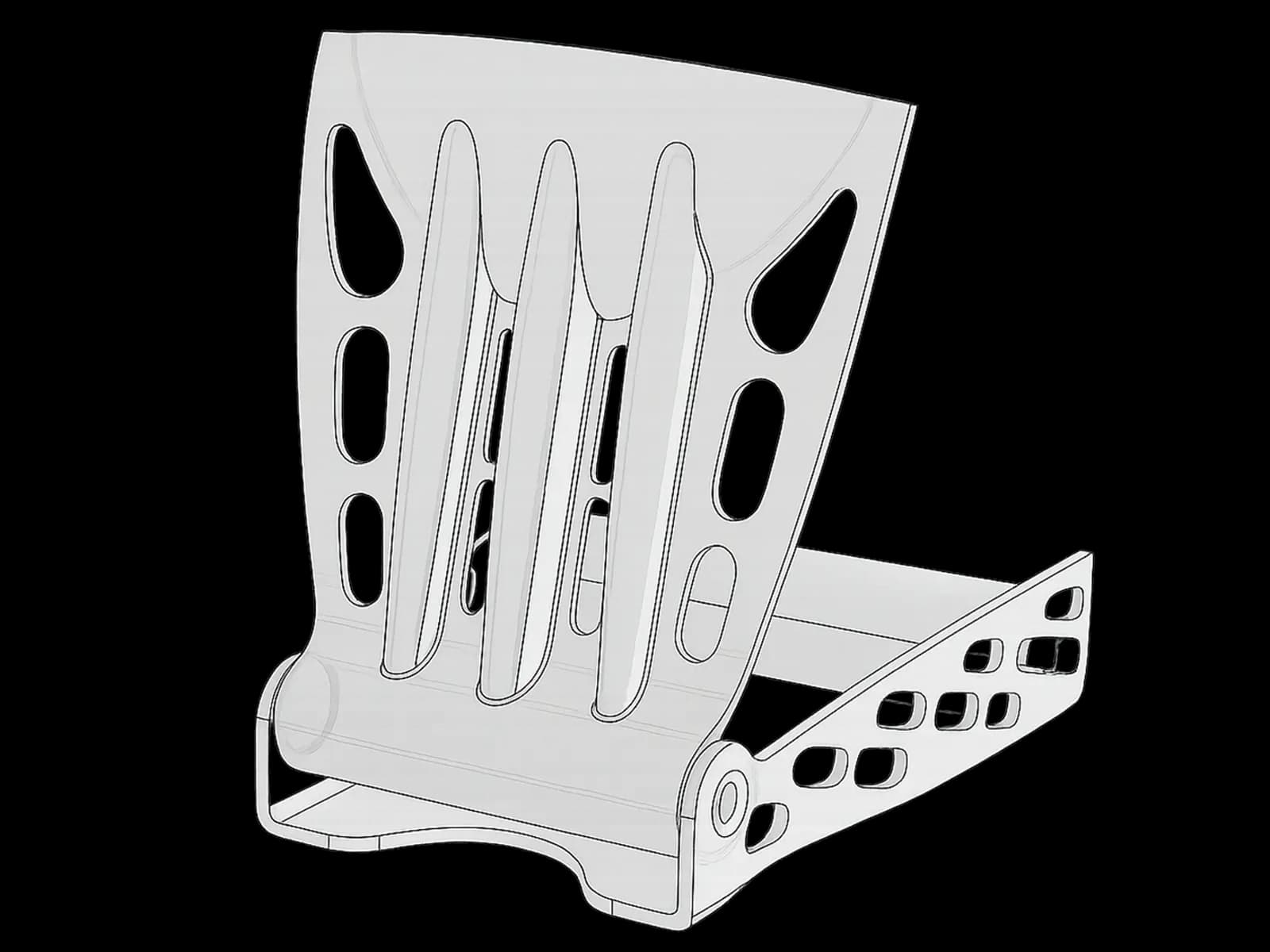

Automotive Dashboard Prototype

Full-scale automotive dashboard prototype with integrated clip features and mounting points

Ready to manufacture your parts?

Upload your CAD files to get instant quotes for FDM 3D printing. Professional-grade manufacturing with fast turnaround times.

Click to start your quote

STL, STEP, OBJ, 3MF supported | Get instant pricing

FDM Questions & Answers

Common questions about FDM 3D printing technology. Can't find what you're looking for? Reach out to our technical team.