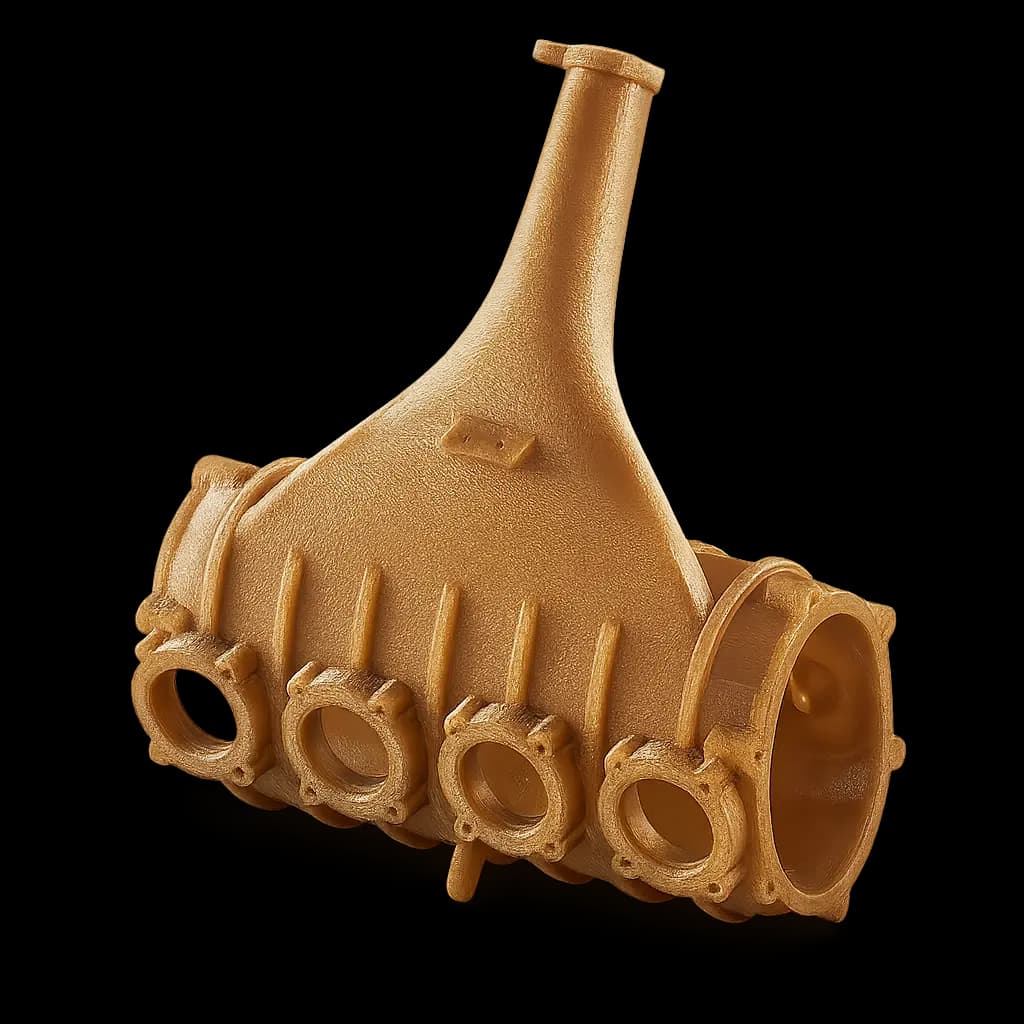

ULTEM 9085 meets stringent aerospace FST requirements while enabling complex geometries impossible with traditional manufacturing. The material's certified grades provide the traceability and consistency required for flight-critical applications.

Key Applications

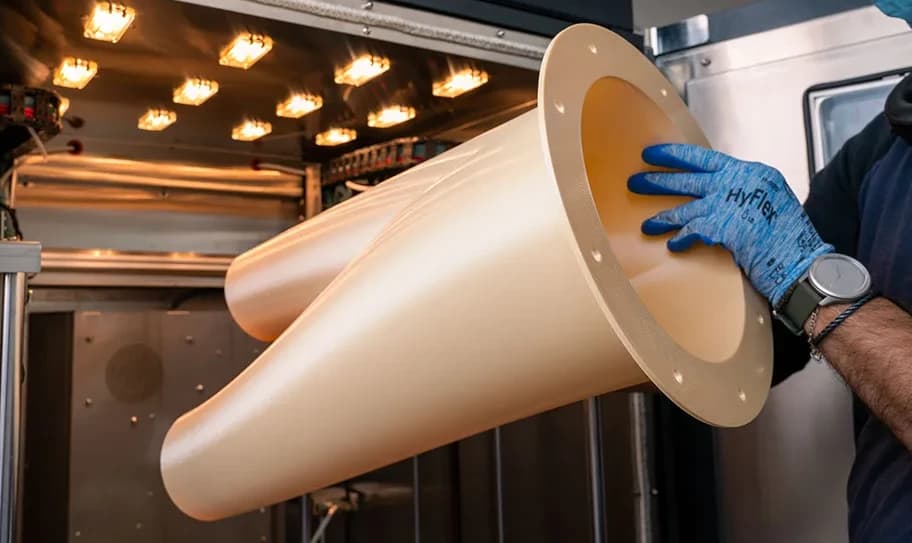

- Aircraft interior panels and ducting systems

- Electrical component housings and wire management

- Custom brackets for avionics and instrumentation

- Environmental control system components

Performance Data

Meets 14 CFR 25.853 with 12-second vertical burn, <200 smoke density, and low toxicity emissions, certified for unlimited cabin use.