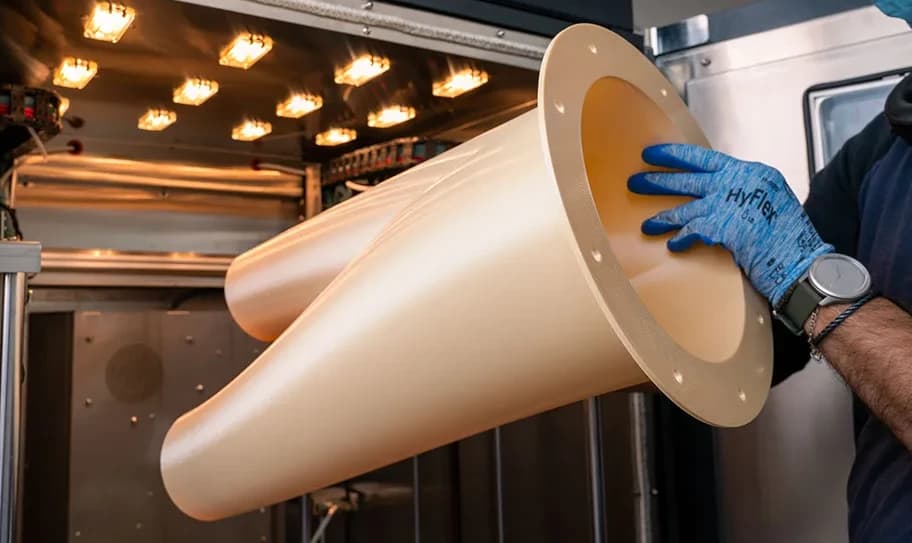

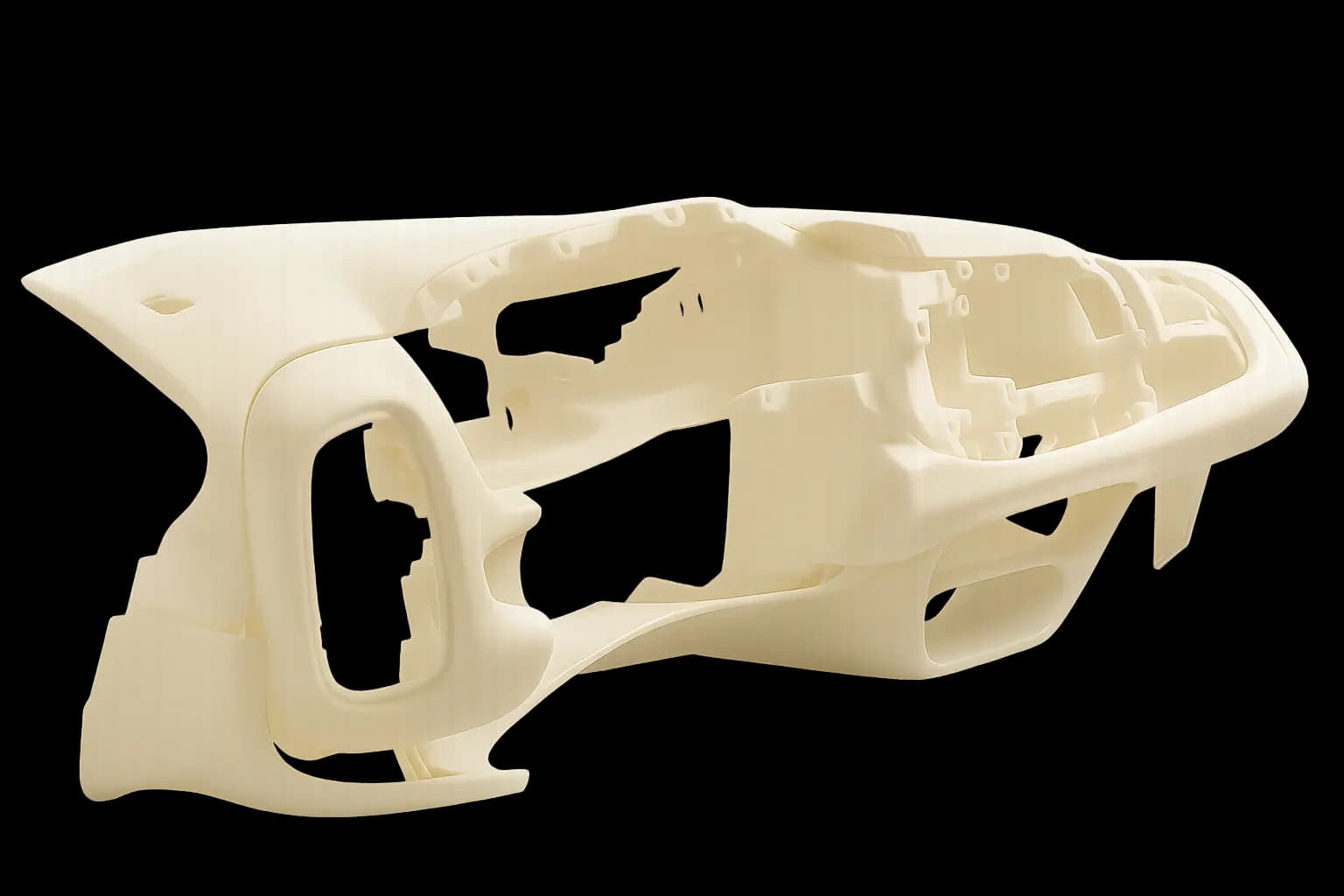

ABS-M30 structural cores sealed with marine coatings keep subsea antenna assemblies neutral and corrosion-resistant while eliminating multi-piece aluminum fabrication. Compound curves print as single bodies that conform to hulls without hand-forming.

Key Applications

- Explorer-class AUV antenna and LED mounting systems with integrated cable routing

- Neutral-buoyancy instrument fairings for long-duration autonomous surveys

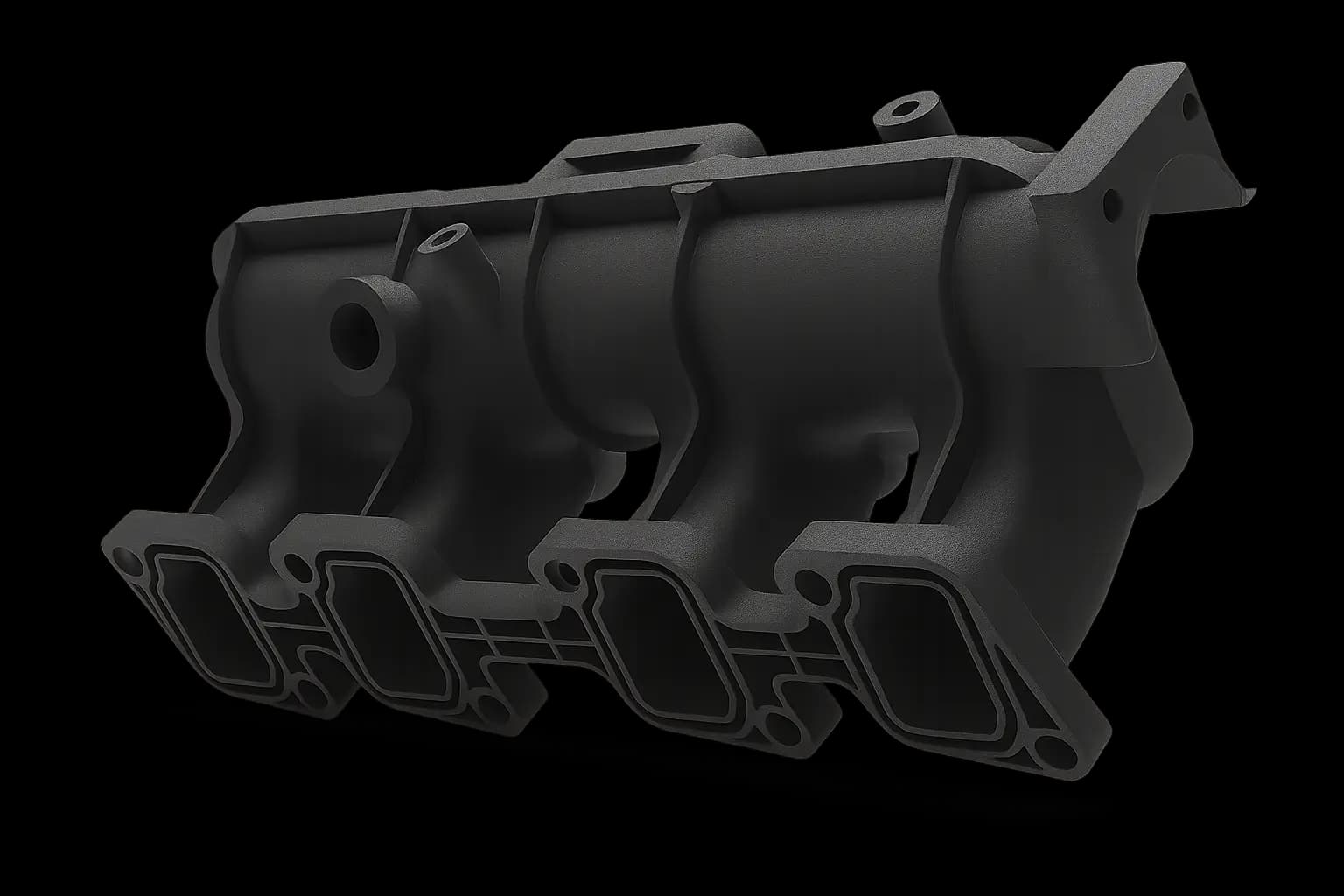

- Pressure-tolerant electronics pods with labyrinth seals and gasket grooves

- Hull drilling templates indexing compound surfaces within ±0.25 mm

Performance Data

International Submarine Engineering cut machining spend by 73% and shrank lead times from 3-4 weeks to 2-3 days by moving antenna mounts to Forge Labs ABS-M30 cores paired with weatherable ASA shells.