Polycarbonate's impact resistance and heat stability make it ideal for automotive applications requiring both structural integrity and aesthetic quality. The material withstands dashboard temperatures up to 120°C while maintaining dimensional accuracy.

Key Applications

- Dashboard components and instrument clusters

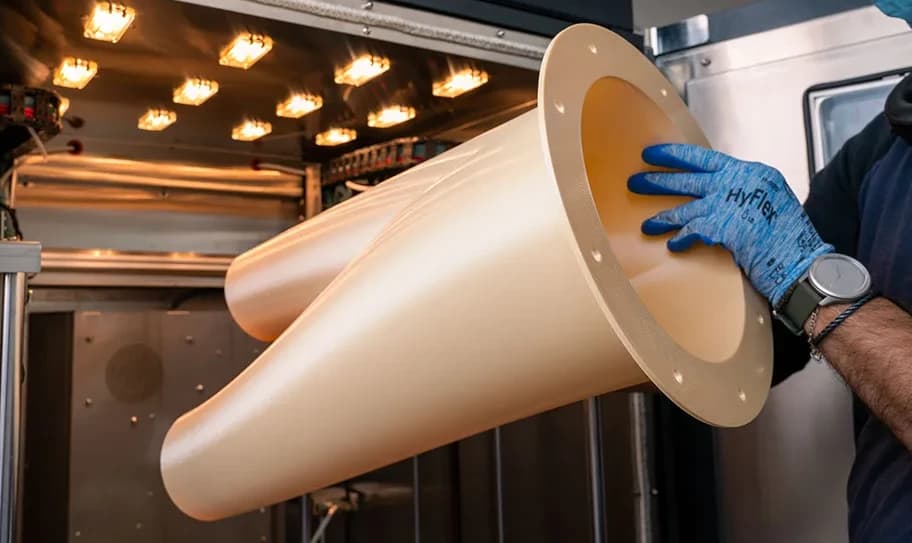

- HVAC ducting and ventilation systems

- Headlight housings and lens prototypes

- Structural brackets and mounting components

Performance Data

Maintains impact strength of 761 J/m (unnotched) after 500 thermal cycles from -40°C to 120°C, exceeding automotive interior requirements.