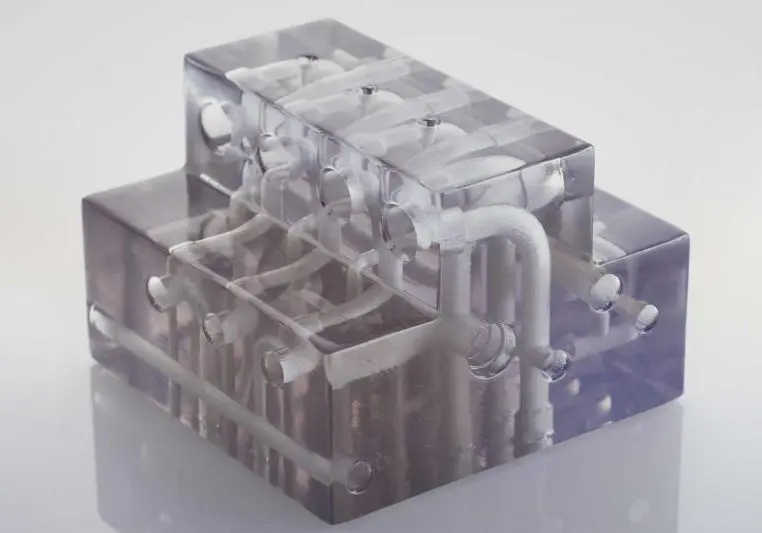

VeroClear enables transparent medical models for education and device development. The material's clarity allows visualization of internal structures and fluid flow paths.

Key Applications

- Anatomical teaching models

- Medical device housings

- Flow visualization prototypes

- Surgical planning models

Performance Data

Achieves 85% light transmission with polishing, enabling clear visualization of internal features down to 0.2mm resolution.