Accelerate Aerospace Developmentwith Advanced 3D Printing

Aerospace prototypes in under 24 hours. Cut costs by up to 90% compared to machining. Flightworthy FST & UL94 rated plastics, resins and metals.

Aerospace Excellence

Revolutionizing Aerospace Manufacturing

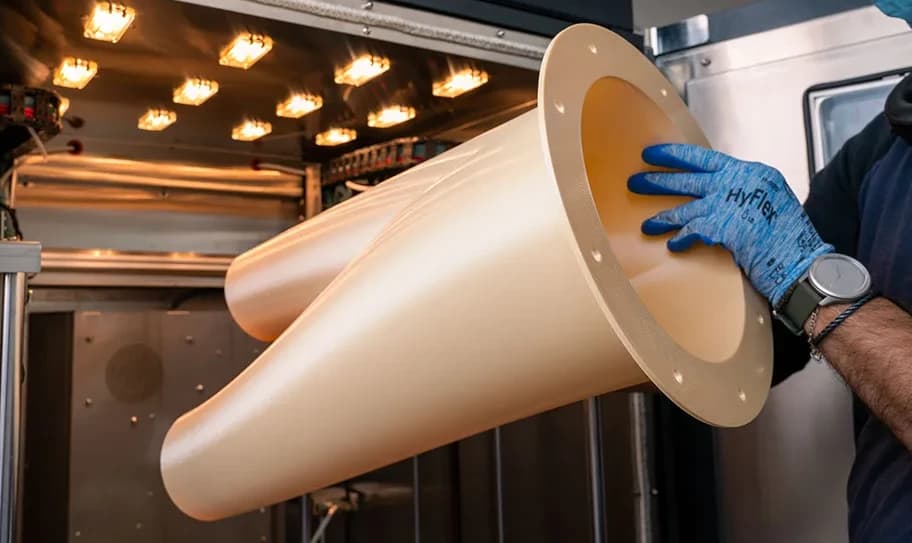

Forge Labs delivers comprehensive solutions for aerospace manufacturing, upholding stringent quality standards and ensuring material traceability with industry-leading reliability. Additive manufacturing revolutionizes aerospace design by enabling unique benefits in crafting aircraft parts, ground equipment, jigs, fixtures, and composite layup tools.

Transforming Aerospace Manufacturing

Forge Labs delivers comprehensive solutions for aerospace manufacturing, upholding stringent quality standards and ensuring material traceability with industry-leading reliability. Additive manufacturing revolutionizes aerospace design by enabling unique benefits in crafting aircraft parts, ground equipment, jigs, fixtures, and composite layup tools.

Key Benefits of 3D Printing in Aerospace

- Eliminate the high cost premium of producing complex aerospace geometries with advanced additive manufacturing.

- Enable rapid customization and design iteration across a comprehensive range of lightweight, high-performance materials.

- Simplify complex multi-component assemblies into single printed parts, dramatically reducing potential failure points and assembly time.

- Achieve significant weight reduction through optimized geometries and lightweight materials, leading to substantial operational cost savings.

- Enable on-demand production of spare parts and components, eliminating long lead times and inventory costs.

- Accelerate prototyping and design validation cycles from weeks to days, enabling rapid innovation and time-to-market advantages.

Industry Standards & Compliance

Certified for Aerospace Excellence

Our manufacturing processes and quality systems meet the most stringent aerospace industry standards, ensuring your parts are ready for critical applications.

FAA Compliance

Full compliance with Federal Aviation Administration requirements for aircraft components and interior parts.

FST Rated Materials

Flame, Smoke, and Toxicity rated materials including ULTEM 9085 and Antero 800NA for aircraft interiors.

Material Traceability

Complete batch tracking and material certification for every component with full documentation chain.

Quality Assurance

Rigorous inspection protocols and quality controls meeting aerospace industry standards and tolerances.

Manufacturing Capabilities

Advanced Aerospace Solutions

From precision prototyping to full-scale production, our comprehensive capabilities deliver results that transform aerospace manufacturing.

Advanced stereolithography (SLA) and direct metal laser sintering (DMLS) technologies deliver aerospace-grade prototypes with exceptional dimensional accuracy and surface quality. SLA achieves tolerances as tight as ±0.2mm on request for critical components, while our 59-inch build volume accommodates large assemblies in a single print. Parts feature intricate details down to 0.5mm resolution with wall thicknesses optimized for structural performance. Every prototype undergoes dimensional verification using calibrated CMM equipment to ensure compliance with aerospace engineering drawings and specifications.

Technical Specifications

Selective laser sintering (SLS) and DMLS enable unprecedented design freedom for aerospace applications. Create internal cooling channels, hollow structures with optimized wall thickness, and biomimetic lattice geometries that maintain structural integrity while minimizing mass. SLS parts require no support structures, allowing for complex overhangs and interlocking assemblies printed as single components. DMLS titanium and aluminum parts achieve aerospace-grade density with isotropic properties matching wrought materials. Topology optimization algorithms reduce material usage by 40-60% while maintaining critical load paths and safety factors required for flight-critical applications.

Technical Specifications

Multi Jet Fusion (MJF) and DMLS technologies excel at producing aerospace components in quantities from single prototypes to hundreds of parts without tooling investments. MJF delivers production-grade nylon parts with uniform mechanical properties throughout the build volume, while DMLS produces flight-ready metal components with full material traceability. Parts maintain consistent quality across batch runs with statistical process control monitoring. Digital inventory management eliminates obsolescence risks for legacy components, allowing on-demand production of discontinued parts decades after original manufacturing.

Technical Specifications

Comprehensive selection of certified aerospace materials with full compliance documentation. ULTEM™ 1010 and 9085 meet FAA flame, smoke, and toxicity requirements for aircraft interiors. Titanium Ti-6Al-4V (Grade 5) provides aerospace-grade strength-to-weight performance with corrosion resistance. Antero™ 800NA offers exceptional chemical resistance and high-temperature stability for engine compartment applications. All materials include certificates of conformance, material test reports, and batch traceability documentation required for aerospace applications. DMLS metals undergo powder analysis, build monitoring, and post-process heat treatment to ensure consistent metallurgical properties.

Technical Specifications

Fused deposition modeling (FDM) with aerospace thermoplastics enables rapid production of maintenance tools, fixtures, and non-critical replacement parts directly at MRO facilities. Large build volume (914 x 609 x 914mm) accommodates substantial tooling and assembly aids. ULTEM™ materials provide chemical resistance to hydraulic fluids, lubricants, and cleaning solvents common in maintenance environments. Custom jigs and fixtures reduce setup times and improve repeatability for complex assembly procedures. Digital part libraries eliminate long-term inventory storage while ensuring immediate availability of critical tooling components.

Technical Specifications

High-definition stereolithography provides exceptional surface quality and dimensional accuracy for fit-check prototypes and functional testing. 50-micron layer resolution captures fine surface details and sharp edges critical for aerodynamic testing and assembly validation. Clear and pigmented resins enable visual inspection of internal features and flow characteristics. Rapid iteration cycles support agile development methodologies with overnight prototype delivery. Multiple materials allow progressive validation from initial concept models through functional prototypes that simulate end-use material properties.

Technical Specifications

Manufacturing Technologies

Proven Technologies for Aerospace

Each technology offers unique advantages for aerospace applications. Choose the right process for your specific requirements.

Selective Laser Sintering

Support-free manufacturing of complex geometries with engineering-grade nylon materials. Ideal for functional prototypes...

DMLS

Flight-grade titanium and aluminum components...

Fused Deposition Modeling

Industry-leading precision with engineering thermoplastics and carbon fiber composites. Excellent for large-format proto...

Stereolithography

Ultra-high resolution resin printing for exceptional surface quality and fine detail. Perfect for concept models, visual...

Not sure which technology is right for your project?

Our application engineers can help you select the optimal manufacturing process based on your specific requirements, materials, and timeline.

Certified Materials

Aerospace-Grade Materials

High-performance materials engineered and certified for demanding aerospace applications with full traceability and compliance documentation.

ULTEM 1010

FST rated for aircraft interiors

Titanium Ti64

Aerospace grade Ti-6Al-4V

Aluminum 6061

Lightweight structural alloy

Nylon PA12

Chemical resistance

Carbon Fiber Nylon

High stiffness-to-weight ratio

Polycarbonate

High impact strength

Explore Our Complete Material Matrix

Compare properties, applications, and certifications across our entire material portfolio. Filter by technology, industry, or specific requirements.

Success Stories

Real results from our aerospace partnerships

Commercial Aircraft Interior Components

Developed custom interior brackets and housings for a major airline, reducing weight by 40% while meeting all FAA requirements for flame, smoke, and toxicity.

UAV Prototype Development

Rapid prototyping and production of unmanned aerial vehicle components using titanium DMLS and carbon fiber reinforced nylon for optimal performance.

Ready to Transform Your Aerospace Manufacturing?

Upload your CAD files for an instant quote or speak with our application engineers about your specific requirements.

Click to start your quote

STL, STEP, OBJ, 3MF supported • Get instant pricing