Nylon 12 CF enables lightweight aerospace tooling and UAV components with stiffness approaching aluminum at half the weight. The material's low coefficient of thermal expansion ensures dimensional stability across temperature ranges.

Key Applications

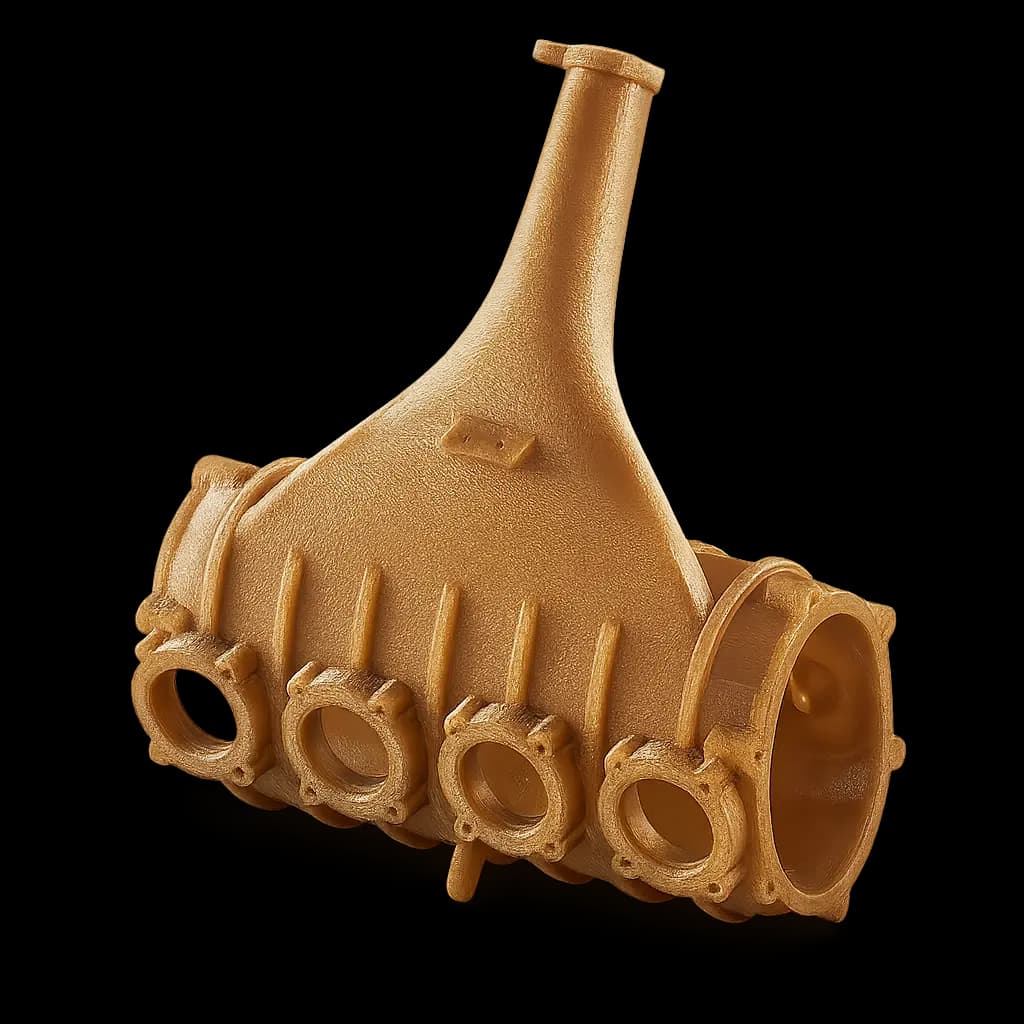

- UAV structural frames and components

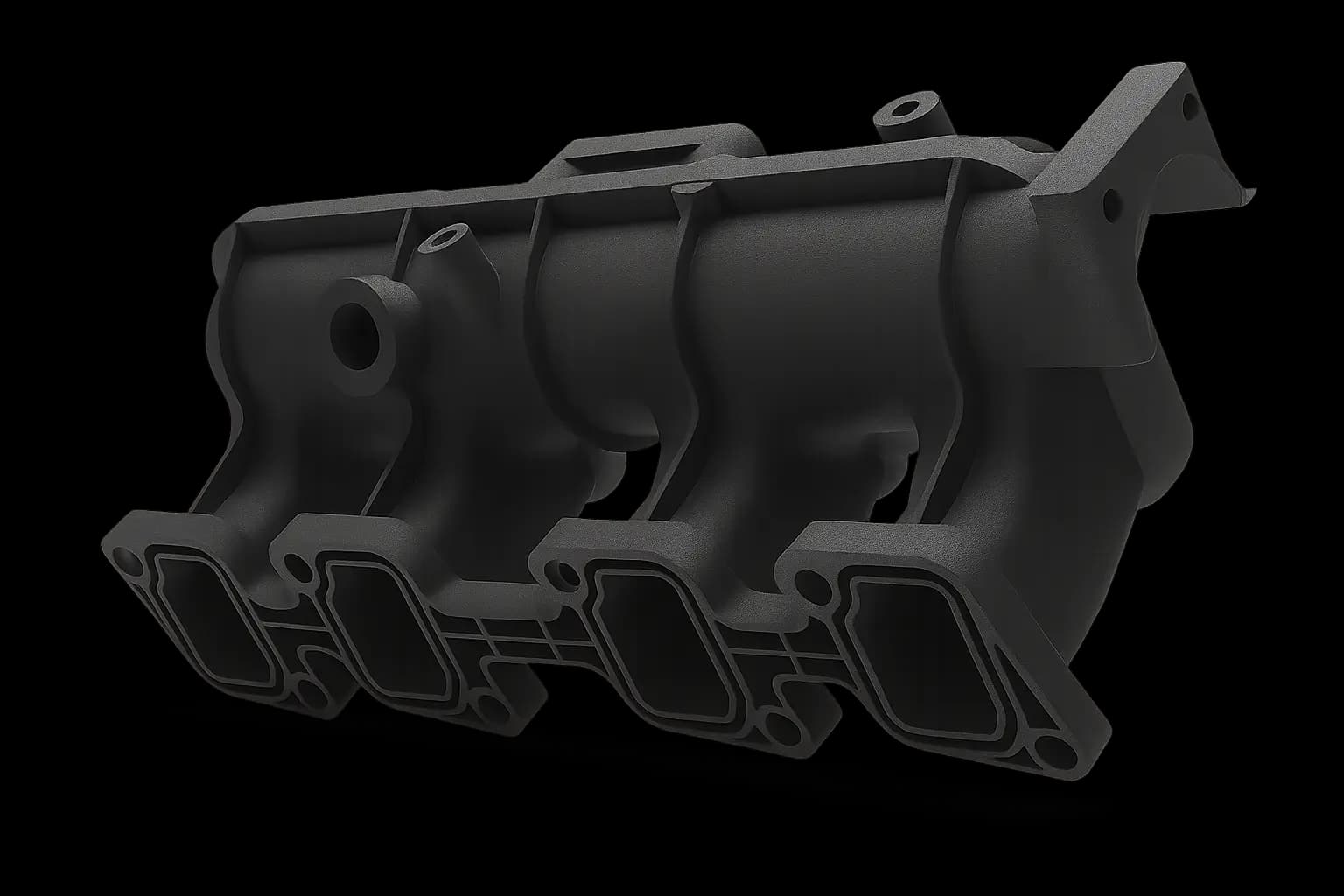

- Composite layup and bonding fixtures

- Satellite panel inserts and brackets

- Ground support equipment components

Performance Data

Achieves specific stiffness of 9.0 GPa·cm³/g, exceeding unfilled polymers by 300% while maintaining <2% moisture absorption for stable performance.