DMLS Ti-6Al-4V enables topology-optimized aerospace components with up to 50% weight reduction versus traditional machining. The process eliminates material waste while achieving buy-to-fly ratios approaching 1:1.

Key Applications

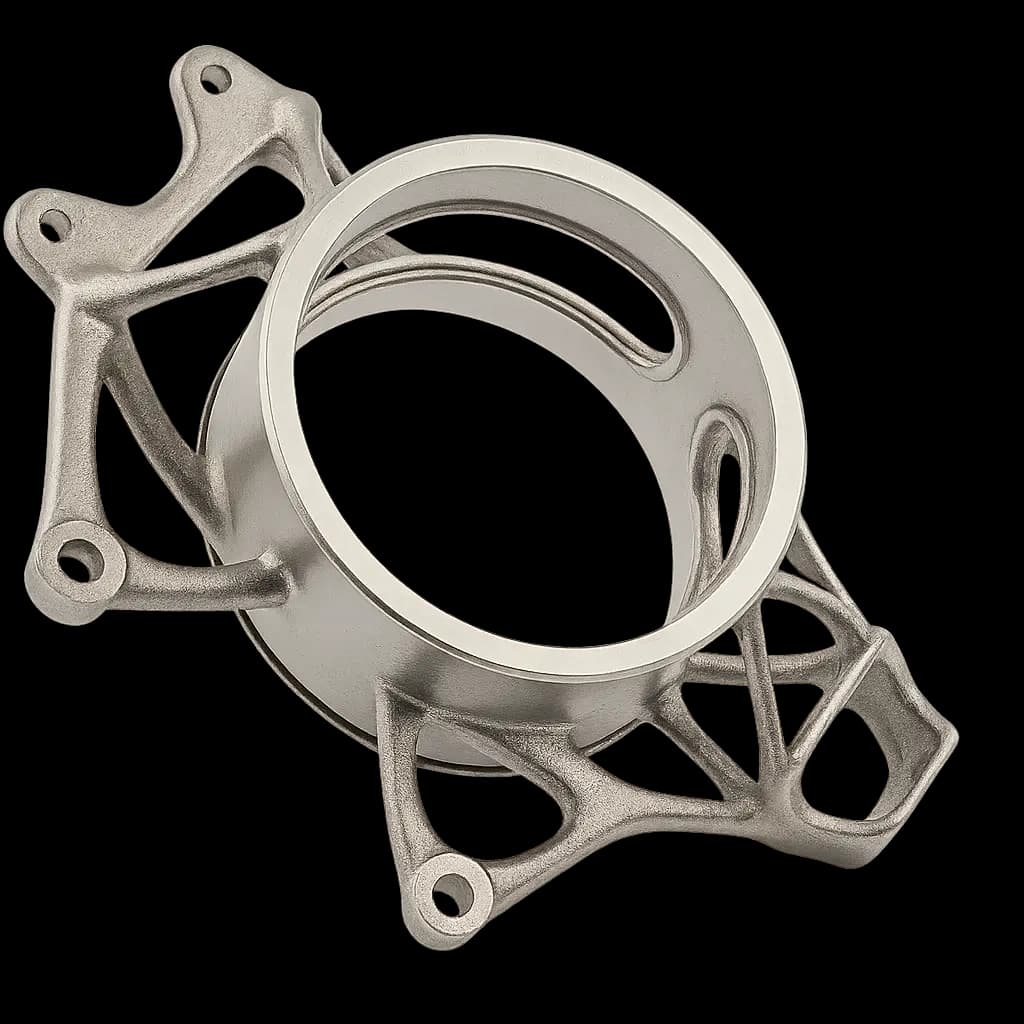

- Topology-optimized brackets and mounting structures

- Satellite components with integrated features

- UAV structural frames and assemblies

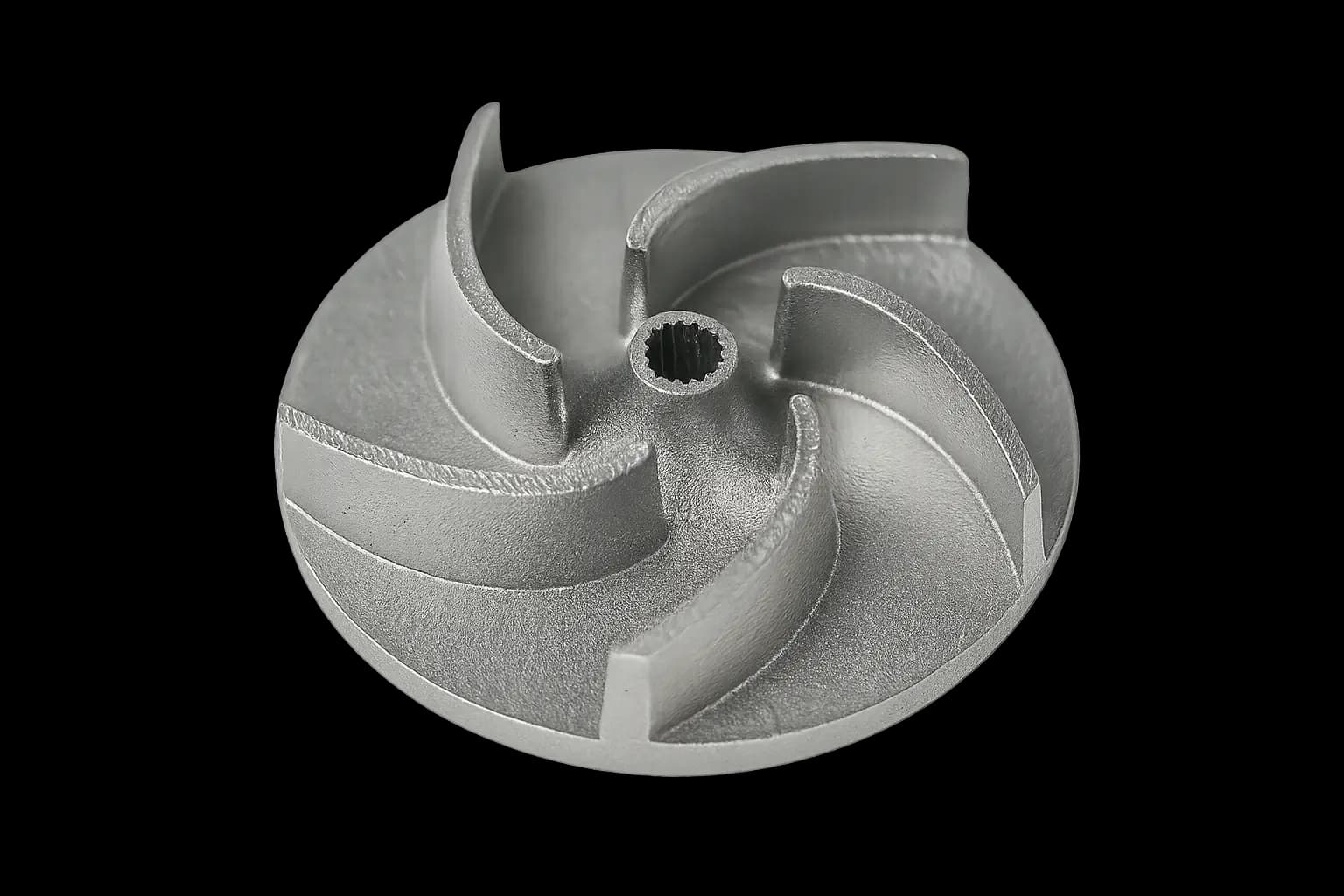

- Turbine blades with internal cooling channels

Performance Data

Meets AMS 4999 and ASTM F2924 specifications with fatigue strength >400 MPa at 10^7 cycles, qualifying for flight-critical applications.