In modern manufacturing, ULTEM materials have become essential for engineers who need components that can withstand high heat, stress, and chemical exposure. As part of the polyetherimide (PEI) family of high-performance thermoplastics, ULTEM offers a unique combination of mechanical strength, thermal endurance, and processability rarely matched by other plastics.

Two grades dominate the field: ULTEM 1010 and ULTEM 9085. Each grade brings a distinct balance of properties that make it valuable for specific industries and functions. ULTEM 1010 excels in heat resistance, mechanical performance, and chemical stability. ULTEM 9085, on the other hand, stands out for its flame retardancy, lightweight strength, and regulatory compliance. For material engineers, product designers, and manufacturing specialists, comparing ULTEM 1010 vs 9085 is a matter of matching material performance with application demands, from aerospace tooling to end-use parts for regulated environments.

ULTEM 1010 Specifications

ULTEM 1010 is one of the strongest, most heat-resistant PEI grades available for additive manufacturing. 1010's exceptional tensile strength and thermal resistance make it well-suited for demanding industrial and aerospace applications, where dimensional stability and chemical integrity are non-negotiable.

Mechanical and Thermal Properties

- Tensile Strength (XZ): 81 MPa ultimate, 64 MPa yield

- Flexural Modulus (XZ): 2,820 MPa

- Heat Deflection Temperature (HDT): 216°C @ 0.45 MPa; 213°C @ 1.82 MPa

- Glass Transition Temperature (Tg): 215°C

- Density: 1.27 g/cm3

These properties make 1010 suitable for load-bearing components and high-temperature fixtures. Its high glass transition temperature provides resistance to thermal creep, allowing the material to maintain structural accuracy in parts exposed to fluctuating heat; this makes it a crucial feature for molds, jigs, and aerospace prototypes.

Chemical and Environmental Resistance

ULTEM 1010's chemical resistance gives it the upper hand in industrial and laboratory environments. It resists automotive fluids, alcohols, and cleaning agents, retaining strength after repeated sterilization cycles. 1010's characteristics explain its integration in medical devices and food processing systems, where consistent performance after sterilization is required. It is also certified to ISO 10993 and NSF 51, making it approved for biocompatible and food-contact applications.

Common ULTEM 1010 Uses

- Aerospace jigs, molds, and fixtures exposed to elevated heat

- Food and beverage tooling that demands FDA-compliant materials

- Medical and dental prototypes that undergo steam sterilization

- Electrical housings and insulators for industrial machinery

- End-use parts requiring both rigidity and repeatable accuracy

Explore more specs and applications on our ULTEM 1010 material page.

ULTEM 9085 Specifications

ULTEM 9085 was specifically developed for sectors where lightweight strength, flame retardancy, and traceability are all mandatory. As one of the few high-performance thermoplastics approved for aerospace use, it meets FAR 25.853 for flame, smoke, and toxicity (FST). These traits make it indispensable for mission-critical 3D printed parts and structural components in transportation industries.

Mechanical and Thermal Properties

- Tensile Strength (XZ): 69 MPa ultimate, 47 MPa yield

- Flexural Modulus (XZ): 2,300 MPa

- HDT: 153°C

- Elongation at Break (XZ): 5.8%

- Density: 1.34 g/cm3

- Flame Rating: UL94 V-0 and FAR 25.853 compliant

While its HDT is lower than ULTEM 1010, 9085's superior impact resistance and flame retardancy make it the top choice for safety-sensitive and regulatory-compliant environments. Plus, its high strength-to-weight ratio supports fuel efficiency and load reduction in aircraft and vehicles.

Processing and Certification Advantages

ULTEM 9085 is widely adopted for FDM 3D printing because of its consistent extrusion behavior and dimensional reliability. Its ability to produce lightweight, traceable, and repeatable parts reduces both waste and development time in aerospace and automotive production lines. And its compliance with aerospace documentation standards means each batch can be verified for performance, a key advantage in quality-controlled industries.

Common ULTEM 9085 Uses

- Aircraft interior components, including ducts, panels, and housings

- Rail and transit systems, where flame resistance and weight reduction are priorities

- Automotive under-hood assemblies and protective housings

- Defense-grade tooling and certified prototypes

- Industrial jigs and fixtures where regulatory compliance is required

See full data and certifications on our ULTEM 9085 material page.

Comparing ULTEM 1010 vs 9085

Though both materials share the ULTEM name and PEI polymer base, their applications diverge. Comparing the two helps highlight some of the critical differences determining which type to select for environment, load, and safety requirements.

| Property | ULTEM 1010 | ULTEM 9085 |

|---|---|---|

| Tensile Strength (XZ) | 81 MPa ultimate (64 MPa yield) | 69 MPa ultimate (47 MPa yield) |

| Heat Deflection Temperature | 216°C @ 0.45 MPa (213°C @ 1.82 MPa) | 153°C |

| Chemical Resistance | Excellent | Good |

| Flame Rating | - | FAR 25.853 / UL94 V-0 |

| Biocompatibility | ISO 10993 / NSF 51 | Not certified |

| FST Compliance | No | Yes |

| Processability | Moderate | High |

ULTEM 1010 delivers the highest heat deflection and chemical stability, ideal for use in sterilization equipment, tooling, and high-temperature production. ULTEM 9085, meanwhile, provides regulatory confidence and process consistency, especially in transportation and aerospace design.

For functional testing and tooling in real-world manufacturing, ULTEM 1010 often serves as the go-to material, while ULTEM 9085 is chosen for flight-ready or certified end-use parts. Both excel at 3D printing for additive manufacturing, producing strong, stable, and lightweight parts that replace traditional metal components.

Their differences allow manufacturers to fine-tune performance: material engineers benefit from 1010's higher mechanical properties in elevated temperatures. Designers and R&D specialists prefer 9085 for its traceable compliance and lower weight-to-strength ratio advantages. But at the end of the day, each material complements the other in a balanced production ecosystem built on precision, reliability, and innovation.

Applications of ULTEM Materials

Aerospace and Defense

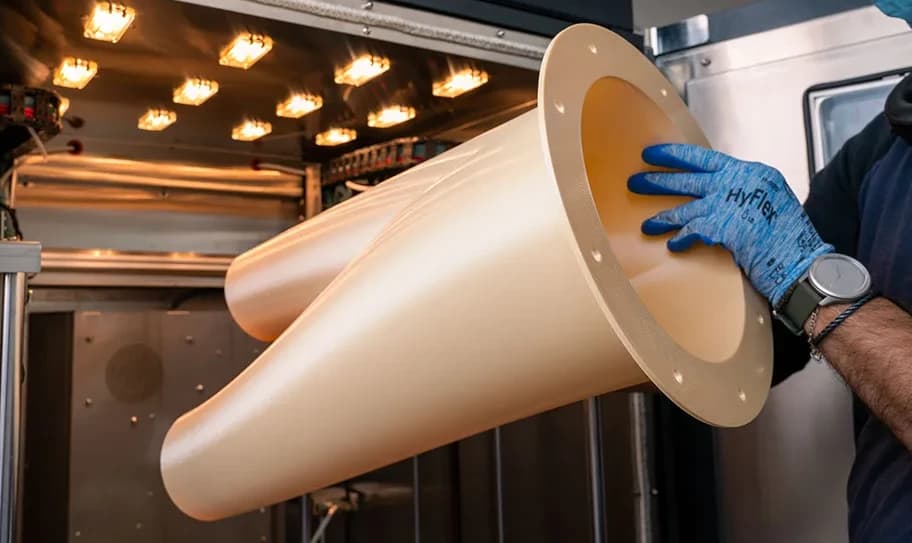

ULTEM 9085 remains a leader in aerospace interiors, where its FST compliance allows for safe, lightweight components such as ducting, wall panels, and housings. It is counted on for end-use parts on commercial and military aircraft. ULTEM 1010, conversely, supports the manufacturing process itself. It is used for thermoforming molds, composite lay-up tools, and high-temperature fixtures, offering durability under repeated autoclave cycles.

Automotive and Transportation

Automotive engineers turn to ULTEM 1010 for under-hood applications exposed to extreme heat and fluids, while ULTEM 9085 is ideal for interior systems that must meet flammability and safety standards. Both help reduce vehicle weight, boost fuel efficiency, and improve recyclability compared to metal or thermoset components.

Medical, Food, and Laboratory Equipment

Because ULTEM 1010 is certified for biocompatibility and food contact, it appears across surgical instruments, sterilization trays, and food-handling components. Its chemical resistance and dimensional stability make it reliable for repeated cleaning and autoclaving. In research labs and clean manufacturing environments, ULTEM's thermal resistance prevents warping or degradation during high-precision testing.

Industrial and Electrical Applications

Both ULTEM grades offer outstanding electrical insulation and mechanical integrity, making them valuable for electronic housings, industrial jigs, and connectors. In high-voltage or high-temperature operations, their resistance to deformation and chemical wear extends product life and reliability.

For more design guides and data on these materials, explore Forge Labs' Resources or visit the material pages for ULTEM 1010 and ULTEM 9085.