Case Study: This article features an exclusive behind-the-scenes look at creating complex movie props for "Come to Daddy" starring Elijah Wood, demonstrating how SLA 3D printing solves unique challenges in film production.

The film industry is a world of make-believe, but the props that bring this world to life need to be as real and detailed as possible. For years, the movie business relied on traditional methods of crafting props—from woodworking to metal casting. While these techniques have their merits, they are often labor-intensive, time-consuming, and restrictive in the complexity of designs they can produce.

Enter stereolithography (SLA) 3D printing—a game-changing technology that offers unparalleled advantages for creating high-quality movie props. This comprehensive guide explores how SLA technology is revolutionizing film production, featuring an exclusive case study of our collaboration with Theta Effects on the complex props for "Come to Daddy," a black comedy feature starring Elijah Wood.

The Challenge: Creating Complex Movie Props

In 2018, Forge Labs collaborated with Theta Effects on a complex prop for "Come to Daddy," a black comedy feature starring Elijah Wood. The film required a particularly challenging effect: Elijah Wood's character needed to have a cast-iron receipt spike stabbed through his cheek—an effect that had to be accomplished with real props rather than CGI.

The final effect showing the 3D printed receipt spike prop in action during filming of "Come to Daddy"

Technical Requirements

The prop presented several critical design and manufacturing challenges:

- Two-Component Design: A false cheek piece to hold the base of the receipt spike, and a spike mounted on a dental appliance inside the mouth

- Extreme Lightweight Construction: The cheek component had to be virtually weightless to hang naturally on the actor's face

- Durability Requirements: Strong enough to withstand multiple takes and handling during filming

- Paintability: Surface suitable for realistic cast-iron finishing

- Rapid Production: Tight film production schedules demanded quick turnaround

- Safety Considerations: All components had to be safe for close contact with the actor

The SLA Solution

Why SLA Technology Was Perfect

Stereolithography (SLA) 3D printing was chosen for this challenging project because it offered unique advantages:

SLA Advantages for Movie Props

- Extreme Detail: Layer heights as fine as 25 microns for realistic surface textures

- Smooth Surface Finish: Minimal post-processing required compared to other 3D printing methods

- Rapid Prototyping: Same-day iterations possible for design changes

- Lightweight Materials: Specialized resins offering ultra-light weight properties

- Paint Compatibility: Excellent surface for professional finishing techniques

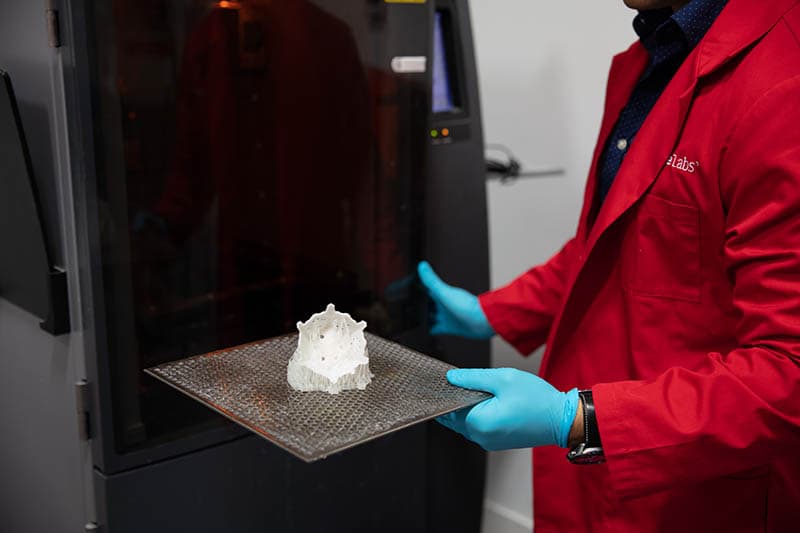

Multiple prop components being simultaneously produced on an SLA 3D printer build platform

Material Selection: Accura XTW

The project utilized Accura XTW, a specialized SLA resin chosen for its unique combination of properties that made it perfect for this demanding application.

Material Properties

- Ultra-lightweight construction

- High durability and impact resistance

- Excellent paint adhesion

- Biocompatible for skin contact

- Dimensional stability

Film Production Benefits

- Safe for extended actor wear

- Lightweight for comfort

- Durable for multiple takes

- Professional paint finish achievable

- Quick production turnaround

Rapid Design Iteration

Working digitally allowed for rapid design modifications throughout the development process. When the initial version moved too much during actor movement, the design was quickly modified to incorporate powerful magnets for stability and reprinted the same day.

Professional Finishing and Results

The success of movie props depends heavily on post-processing techniques that transform 3D printed parts into convincing real-world objects.

The final painted prop showing realistic cast-iron appearance achieved through professional finishing techniques by Theta Effects

Professional Paint Finishing

Theta Effects painted the part to mimic the look of cast-iron, demonstrating the excellent paint compatibility of SLA printed parts. The smooth surface finish of SLA parts makes them ideal for professional painting techniques, requiring minimal surface preparation.

SLA vs Traditional Prop Making

| Factor | Traditional Methods | SLA 3D Printing |

|---|---|---|

| Production Time | Weeks to months | Days to weeks |

| Design Changes | Start over completely | Update file and reprint |

| Detail Level | Limited by tool access | 25-micron precision possible |

| Multiple Copies | Each made individually | Batch production possible |

Industry Applications

Film Genres and Use Cases

Science Fiction & Fantasy

- Futuristic devices and gadgets

- Alien artifacts and technology

- Weapon props and armor

- Complex mechanical components

Horror & Thriller

- Gore effects and trauma props

- Creature prosthetic elements

- Safe weapon replicas

- Supernatural objects

Conclusion

Stereolithography (SLA) 3D printing has fundamentally transformed the movie prop industry, offering unprecedented design freedom, cost efficiency, and production speed. The success of projects like the "Come to Daddy" receipt spike prop demonstrates how this technology solves real-world challenges that were previously insurmountable.

As demonstrated in our collaboration with Theta Effects, SLA technology enables prop makers to achieve extreme lightweight construction without sacrificing durability, iterate designs rapidly to solve unexpected challenges, and deliver professional results within tight production timelines.

Ready to bring your film vision to life? Our SLA 3D printing services specialize in movie prop creation, offering the same expertise that brought Elijah Wood's complex effect to the screen. Contact us at sales@forgelabs.com to discuss your next film project.