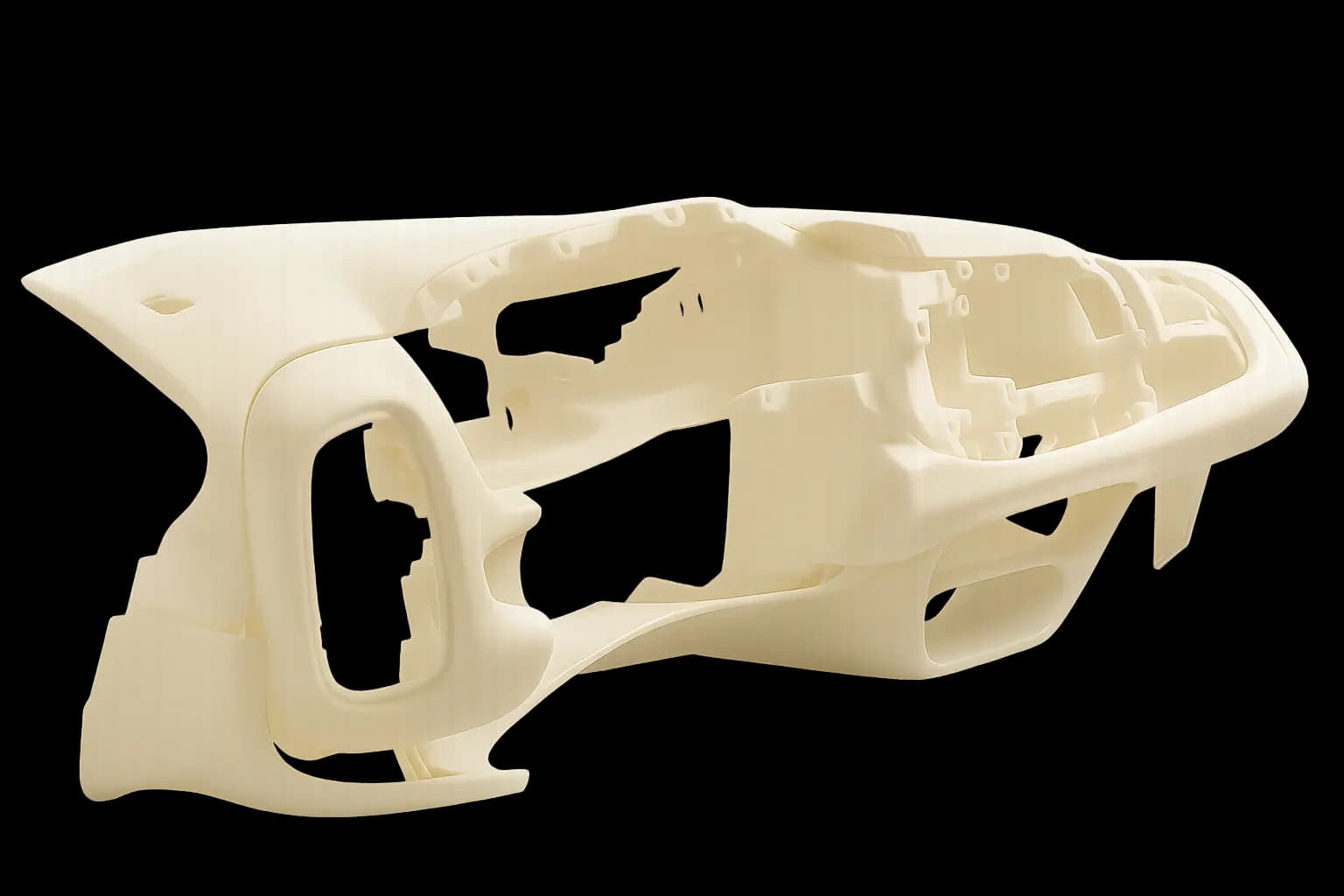

Accura 25 enables rapid iteration of interior components and design validation models with the surface quality and mechanical properties required for functional testing. The material's large build capability allows full-scale dashboard and console prototypes in single builds.

Key Applications

- Full-scale dashboard and console prototypes

- Functional air vents with moving louvers

- Interior trim components for fit testing

- Headlight and taillight housings

Performance Data

Maintains dimensional accuracy of ±0.2% across 1500mm builds, enabling accurate fit testing of multi-component assemblies.