USP Class VI ClearVue enables patient-specific surgical guides and instrument prototypes with certified biocompatibility. The material's clarity allows visualization while maintaining medical safety.

Key Applications

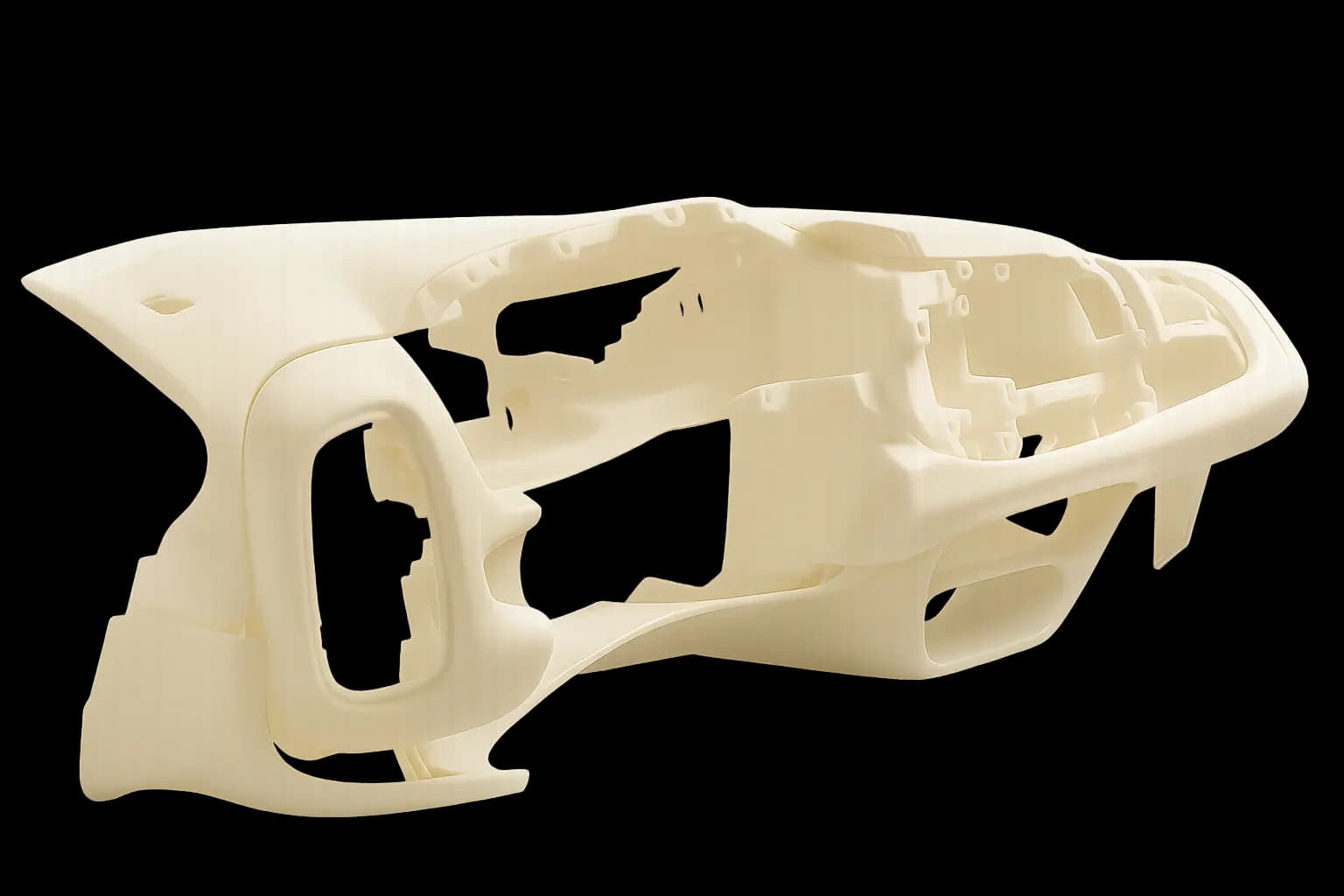

- Patient-specific surgical guides

- Surgical instrument prototypes

- Temporary implant models

- Surgical training models

Performance Data

Maintains biocompatibility after steam sterilization at 134°C, with documented USP Class VI certification for FDA submissions.