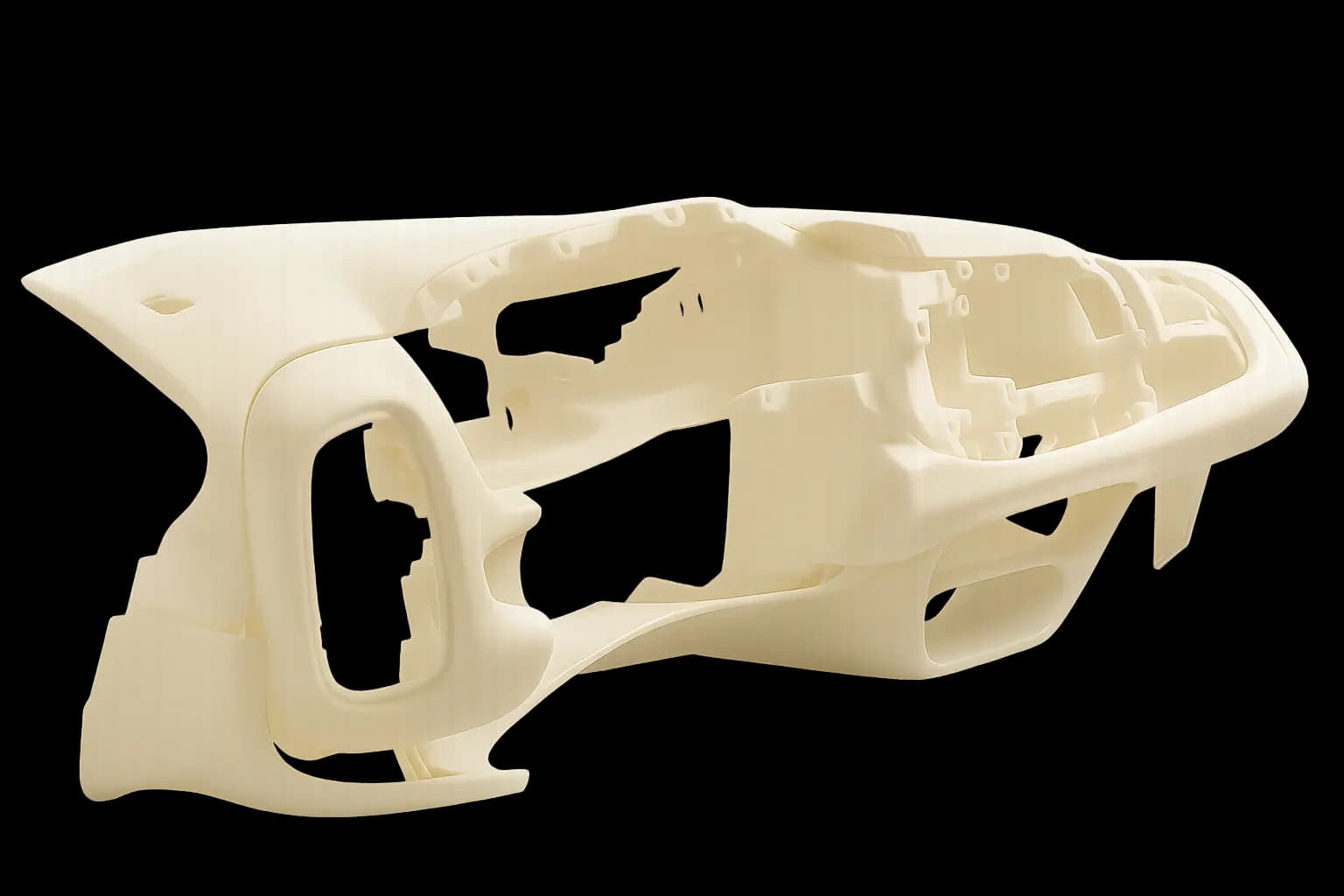

Accura Xtreme White 200's bright white finish and good surface quality make it ideal for design models and appearance prototypes. The material accepts paint and other finishes well for presentation models.

Key Applications

- Concept models and design studies

- Appearance prototypes for client review

- Painted presentation models

- Form study models

Performance Data

Achieves smooth surface finish with Ra 3-5 μm, providing excellent base for painting and finishing operations.