Innovation Success: Robbox Tools achieved remarkable cost savings and development speed using FDM 3D printing, reducing prototype costs by 50-100x and accelerating development by 10x while winning the prestigious Pinnacle Innovation Award.

"If we had to injection mold the prototypes, it would be 20k for just one drill - and that would be just to do it once. If you make a modification (which we do every day) then you have to redo everything. 3D printing saves an enormous amount of time and money."- Andy Matei, Robbox Founder & President

Robbox Tools revolutionized their product development process by leveraging FDM 3D printing to rapidly iterate on smart power tool enclosures. Rather than produce expensive injection molded prototypes, they achieved functional validation at a fraction of traditional costs while dramatically reducing design time and risk.

FDM-printed prototype iterations demonstrating rapid design evolution and validation

Company Overview: Robbox Smart Tools

Robbox is an innovative smart tool manufacturer developing a complete lineup of robotic hand tools that use intelligent technology to automatically adapt to various home and industrial tasks while providing real-time feedback to operators. Their approach combines traditional tool functionality with advanced sensors, processors, and adaptive algorithms.

Product Innovation Focus

Smart Technology Integration

- Adaptive Intelligence: Tools automatically adjust to task requirements

- Real-time Feedback: Continuous performance monitoring and guidance

- User Interface: Intuitive controls and status indicators

- Sensor Integration: Advanced sensing for precision control

Market Position

- Industry Recognition: Pinnacle Innovation Award winner

- Startup Efficiency: Small team, rapid development cycles

- Product Range: Comprehensive smart tool ecosystem

- Technology Leadership: Pioneer in robotic hand tools

The Prototyping Challenge

As a small company competing in the power tools market, Robbox faced significant challenges in developing competitive products within limited budgets and timeframes. Traditional prototyping methods presented insurmountable barriers to their innovation goals.

Traditional Manufacturing Constraints

Injection Molding Limitations

- Prohibitive Costs: $20,000+ per prototype iteration

- Long Lead Times: 2-6 weeks minimum turnaround

- Modification Penalties: Complete tooling restart for each change

- High Risk: Expensive validation of unproven designs

- Limited Iterations: Cost barriers prevent thorough optimization

CNC Machining Barriers

Alternative manufacturing approaches also presented significant obstacles:

- Metal Machining: Excessive weight inhibited electronics functionality

- Plastic Machining: Impossible to achieve required thin wall sections

- Complex Geometries: Internal features and undercuts not feasible

- Cost Inefficiency: High setup costs for small quantities

- Material Waste: Subtractive process inefficient for complex shapes

FDM Technology Selection

Fused Deposition Modeling (FDM) emerged as the optimal solution for Robbox's prototyping requirements, offering the perfect combination of speed, cost-effectiveness, and material properties necessary for functional validation.

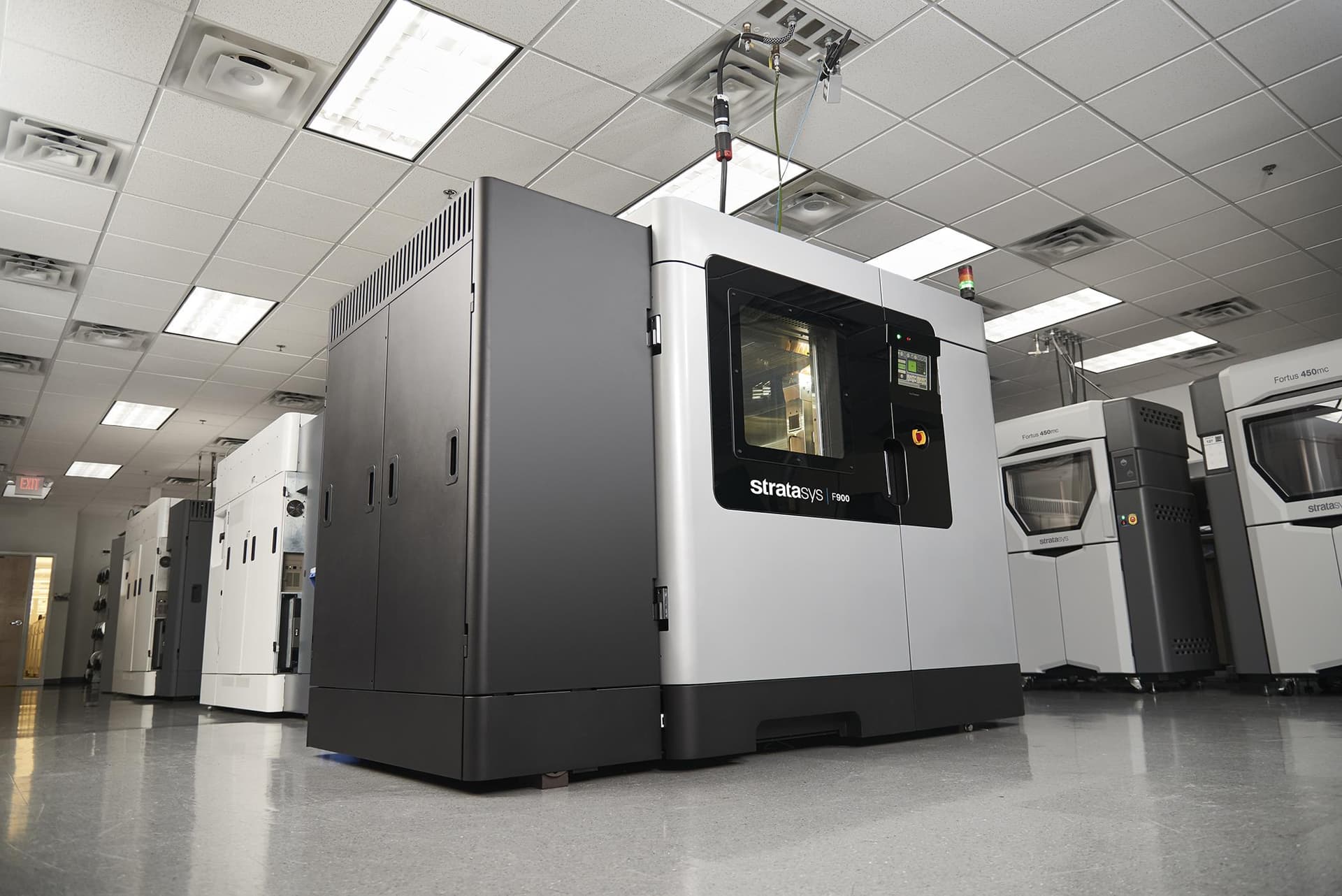

Industrial-grade Stratasys Fortus 900 FDM system enabling high-quality prototype production

FDM Advantages for Product Development

| Capability | FDM Advantage | Project Benefit |

|---|---|---|

| Build Volume | Large build platforms | Full-size tool enclosures |

| Material Range | Production-grade thermoplastics | Real-world material testing |

| Speed | Fast print times | Rapid iteration cycles |

| Cost | Competitive pricing | Multiple iterations feasible |

| Complexity | Complex internal features | Advanced enclosure designs |

Material Selection: ASA and ABS

For the Robbox prototypes, ASA (Acrylonitrile Styrene Acrylate) and ABS (Acrylonitrile Butadiene Styrene) were selected for their robust properties and ease of finishing, making them ideal for both functional testing and presentation purposes.

ASA Material Properties

- UV Resistance: Excellent outdoor stability

- Chemical Resistance: Superior chemical compatibility

- Impact Strength: High toughness for tool applications

- Temperature Stability: Maintains properties at elevated temperatures

- Surface Quality: Excellent finish for professional appearance

ABS Material Properties

- Mechanical Strength: High tensile and flexural strength

- Post-Processing: Easy to sand, paint, and finish

- Dimensional Stability: Low shrinkage and warping

- Impact Resistance: Excellent toughness for durability testing

- Electrical Properties: Good insulation for electronics

Robotic Drill Enclosure Development

The Robotic Drill represented Robbox's flagship product, requiring an enclosure that balanced weight constraints, ergonomics, and electronics integration while maintaining the aesthetic appeal necessary for market success.

"As a small company, we can't afford to waste any time - we have to be fast. With FDM prototypes, we were able to accelerate our development by a factor of 10, making it possible to bring multiple products near completion within a year."- Andy Matei, Robbox Founder & President

FDM-printed robotic drill enclosure demonstrating thin-wall construction and sophisticated internal features

Design Requirements and Constraints

The Robotic Drill enclosure presented unique engineering challenges that traditional manufacturing methods could not address cost-effectively:

- Thin Wall Construction: Minimized weight while maintaining structural integrity

- Ergonomic Optimization: Comfortable grip and balance for extended use

- Electronics Integration: Precise internal features for sensor and processor mounting

- Heat Management: Ventilation features and thermal isolation zones

- Aesthetic Appeal: Professional appearance suitable for trade shows and demos

- Functional Testing: Full functionality for performance validation

Cost and Timeline Comparison

Robotic Drill Prototype Economics

FDM 3D Printing

Traditional Manufacturing

50-100x Cost Reduction • 10x Speed Improvement

Technical Achievements

The FDM-printed drill enclosure successfully addressed all critical requirements while enabling rapid design optimization:

Key Technical Successes

- Weight Optimization: Achieved target weight through thin-wall construction

- Electronics Integration: Perfect fit for sensors and control systems

- Functional Validation: Full operational testing of smart features

- Aesthetic Quality: Professional appearance suitable for demonstrations

- Rapid Iteration: Multiple design cycles within project timeline

- Market Validation: Industry recognition through Pinnacle Innovation Award

Robotic Driver and Modular Attachments

The Robotic Driver project expanded the complexity of prototyping requirements, featuring a modular platform with hundreds of interchangeable attachments, each requiring individual optimization and validation.

"We are developing hundreds of attachments, and every single attachment requires so many alterations and changes to get it right. 3D printing is necessary for rapid iteration."- Robbox Development Team

FDM-printed robotic driver featuring modular attachment interface and ergonomic enclosure design

Modular Platform Strategy

The Robotic Driver was conceived as an intelligent platform with swappable attachments designed to replace a comprehensive range of traditional tools, reducing cost per tool and storage requirements while maximizing functionality.

Platform Benefits

- Cost Efficiency: Shared intelligence across multiple tools

- Space Optimization: Reduced storage footprint

- Upgrade Path: New attachments extend functionality

- User Learning: Consistent interface across applications

Development Challenges

- Interface Standardization: Universal attachment mechanism

- Electronics Integration: Power and data transmission

- Ergonomic Optimization: Balance across diverse attachments

- Volume Management: Hundreds of unique designs

Comprehensive range of FDM-printed tool attachments demonstrating modular system flexibility

Rapid Iteration Workflow

The scale of the attachment development program demanded an efficient iteration workflow that FDM 3D printing uniquely enabled. Using a Stratasys F170 system, overnight turnaround became the development standard.

- Design Phase: CAD development and optimization based on previous iteration feedback

- Print Preparation: Print setup and queuing for overnight production

- Morning Evaluation: Physical testing and performance assessment

- Feedback Integration: Design modifications based on test results

- Next Iteration: Cycle repetition for continuous improvement

Economics of Attachment Development

Robotic Driver Attachment Economics

FDM 3D Printing

Traditional Manufacturing

For 100 Attachments: FDM $15,000 vs Traditional $1,000,000

Post-Processing and Finishing

Beyond functional validation, the FDM prototypes required professional finishing to serve dual purposes as both test articles and presentation models for trade shows and investor demonstrations.

Professional Finishing Workflow

The transition from functional prototype to presentation-ready model involved systematic post-processing techniques:

- Support Removal: Careful extraction of support structures to preserve surface quality

- Surface Preparation: Sanding and smoothing to eliminate layer lines

- Primer Application: Base coating for paint adhesion and surface uniformity

- Color Matching: Professional paint application matching production intent

- Assembly Integration: Electronics installation and functional testing

- Quality Validation: Final inspection and performance verification

Presentation Quality Results

The finished prototypes achieved injection-molded appearance quality while maintaining full functionality, enabling Robbox to present their innovations confidently at industry events and investor meetings.

Presentation Benefits

- Professional Appearance: Indistinguishable from production parts

- Functional Demonstration: Full smart tool capabilities showcased

- Investor Confidence: Tangible proof of concept and market readiness

- Trade Show Success: Pinnacle Innovation Award recognition

- Market Validation: Positive reception from industry professionals

- Cost Effectiveness: High-quality presentation at prototype costs

Industry Recognition and Awards

The success of Robbox's FDM-printed prototypes culminated in winning the prestigious Pinnacle Innovation Award at the Las Vegas National Hardware Show, validating both their technology approach and manufacturing methodology.

Pinnacle Innovation Award Significance

The Pinnacle Innovation Award represents recognition from industry leaders for exceptional innovation in hardware and tools. Robbox's achievement with FDM-printed prototypes demonstrates the technology's viability for high-stakes product development.

Award Impact

- Industry Validation: Professional recognition of innovation

- Market Credibility: Third-party endorsement of technology

- Investor Interest: Increased funding opportunities

- Media Attention: Industry press coverage and exposure

Technology Demonstration

- FDM Viability: Proof of concept for production development

- Speed Advantage: Rapid iteration enabling innovation

- Cost Efficiency: Affordable development for startups

- Quality Achievement: Professional results from prototypes

Lessons for Product Development

Strategic Implications for Startups

Robbox's success illustrates how strategic use of additive manufacturing can level the playing field for innovative startups competing against established manufacturers with traditional production capabilities.

Startup Advantages Through FDM

- Low Barrier to Entry: Minimal capital investment for prototyping

- Rapid Market Response: Quick adaptation to market feedback

- Risk Mitigation: Low-cost validation before major investment

- Innovation Speed: Faster development cycles than competitors

- Resource Efficiency: Small teams achieving large company results

- Flexibility Advantage: Easy design changes without tooling penalties

Best Practices for FDM Prototyping

The Robbox case study reveals several critical success factors for effective FDM prototyping in product development:

- Material Selection: Choose materials that match production intent properties

- Iteration Planning: Design development process around rapid cycles

- Quality Standards: Establish finishing protocols for presentation needs

- Functional Testing: Validate all critical performance requirements

- Economics Focus: Leverage cost advantages for comprehensive testing

- Timeline Management: Use speed advantages for competitive positioning

Technology Recommendations

When to Choose FDM for Prototyping

| Application | FDM Suitability | Key Benefits |

|---|---|---|

| Large Enclosures | Excellent | Build volume, cost efficiency |

| Functional Testing | Excellent | Engineering materials, durability |

| Rapid Iteration | Excellent | Fast turnaround, low cost |

| Multiple Variants | Excellent | No tooling constraints |

| Presentation Models | Good with finishing | Post-processing capability |

Ready to accelerate your product development? Our consumer electronics and automotive teams can help you leverage FDM prototyping for faster, more cost-effective development cycles. Contact us at sales@forgelabs.com to discuss your project requirements.

Conclusion: FDM as Innovation Enabler

The Robbox Tools case study demonstrates how FDM 3D printing serves as more than a prototyping tool—it becomes an innovation enabler that transforms what's possible for small companies competing in established markets. By achieving 50-100x cost reductions and 10x speed improvements, FDM prototyping enabled Robbox to develop award-winning products that might otherwise have been impossible within their resource constraints.

The success factors—material selection, rapid iteration workflows, professional finishing, and strategic cost management—provide a roadmap for other companies seeking to leverage additive manufacturing for competitive advantage. Most importantly, the industry recognition through the Pinnacle Innovation Award validates that FDM prototypes can achieve the quality and performance standards necessary for market success.

Project Success Metrics

- 50-100x cost reduction achieved

- 10x development acceleration delivered

- 2-day turnaround vs 2-6 week traditional

- Hundreds of attachments rapidly prototyped

- Pinnacle Innovation Award won

- Full functional validation completed

- Professional presentation quality achieved

- Market-ready products developed in under one year

For startups and established companies alike, the Robbox example illustrates that strategic adoption of FDM 3D printing can fundamentally change the economics and timelines of product development, enabling innovation that drives market success.