Museum Innovation Spotlight: 3D printing is revolutionizing how museums preserve artifacts, engage visitors, and democratize access to cultural heritage through innovative replication, interactive exhibits, and digital preservation strategies.

In a world where technology is rapidly evolving, museums are embracing innovative approaches to bring history, art, and science closer to the public. One technology proving to be a game-changer for the museum experience is 3D printing. Far from being just a futuristic novelty, 3D printing offers practical, educational, and conservation-oriented applications that are fundamentally transforming how we experience and preserve cultural heritage.

3D printed museum exhibits enable hands-on interaction while preserving precious original artifacts

The Evolution of Museum Technology

Museums have long been guardians of human knowledge, artistic achievement, and scientific discovery. However, traditional display methods often create barriers between visitors and artifacts, limiting engagement to visual observation. The integration of 3D printing technology is breaking down these barriers, creating new possibilities for education, preservation, and accessibility.

From Passive Observation to Active Engagement

Traditional museum experiences rely heavily on "look but don't touch" policies, necessary for protecting irreplaceable artifacts but limiting educational impact. 3D printing transforms this paradigm by enabling museums to create precise replicas that visitors can handle, examine closely, and use for learning without risking damage to originals.

Traditional Museum Challenges

- Limited Interaction: Visual-only experiences

- Preservation Risks: Light, temperature, handling damage

- Access Barriers: Fragile items behind glass

- High Costs: Traditional casting and molding

- Storage Issues: Space constraints for replicas

- Transport Limitations: Fragile artifact movement

3D Printing Solutions

- Tactile Learning: Hands-on exploration

- Original Protection: Controlled storage conditions

- Enhanced Access: Interactive touchable replicas

- Cost Efficiency: Digital reproduction scalability

- Space Optimization: Digital storage, on-demand printing

- Global Sharing: Digital files for worldwide access

Customization: Tailoring the Museum Experience

The flexibility of 3D printing allows for incredible levels of customization in museum displays. Whether resizing an artifact to fit a particular display case, creating enlarged models to reveal intricate details, or producing cross-sections to show internal structures, the technology provides museums with unparalleled control over how they present their collections.

Adaptive Display Solutions

Museums can now adapt artifacts to their exhibition needs rather than designing exhibitions around artifact constraints. This flexibility enables greater storytelling possibilities and significantly enhances the thematic and narrative flow of exhibits.

Customization Applications

Scale Modifications

- • Enlarged models for detail examination

- • Reduced sizes for space-constrained displays

- • Multiple scales for comparative analysis

- • Child-friendly proportions for educational programs

Educational Enhancements

- • Cross-sectional views revealing internal structure

- • Color-coded anatomical features

- • Removable components for assembly demonstrations

- • Tactile surfaces for visually impaired visitors

Contextual Adaptations

- • Period-appropriate finishing and coloring

- • Reconstructed missing portions

- • Multiple preservation states

- • Interactive puzzle formats

Technical Modifications

- • Reinforced structures for handling

- • Modular designs for transport

- • Mounting systems integration

- • Interactive mechanical features

Preserving the Fragile Past for a Sustainable Future

One of the critical challenges museums face is preserving delicate artifacts. Exposure to light, temperature changes, and even oils and dirt from human skin can lead to degradation over time. 3D printing allows museums to create exact replicas of precious items, enabling original artifacts to be stored in optimal controlled conditions while ensuring public access to their beauty and historical significance.

Conservation Benefits

Traditional conservation methods often involve complex environmental controls and limited public access. 3D printing creates a preservation strategy that protects originals while maintaining educational and cultural accessibility.

| Conservation Aspect | Traditional Approach | 3D Printing Solution | Benefits |

|---|---|---|---|

| Light Exposure | UV filtering, limited lighting | Original in dark storage, replica on display | Zero light damage to original |

| Physical Handling | Protective barriers, gloves | Durable replicas for interaction | Enhanced visitor engagement |

| Environmental Control | Gallery climate systems | Optimal storage, normal display conditions | Reduced operational costs |

| Transport Risk | Specialized shipping, insurance | Digital file sharing, local printing | Global accessibility |

Digital Preservation and Archiving

The digital nature of 3D models means they can be archived indefinitely, ensuring that the intellectual and cultural value of artifacts is preserved for future generations. If an original artifact is lost or damaged, a replica can be produced from the stored digital model, providing crucial backup against loss.

Digital Heritage Advantages

- Permanent Storage: Digital files don't degrade over time

- Global Access: Worldwide sharing without physical transport

- Multiple Formats: Different resolutions for various applications

- Research Applications: Advanced analysis and measurements

- Educational Resources: Classroom and online learning materials

- Disaster Recovery: Backup against loss or damage

- Collaborative Research: International scholarly cooperation

Cost-Effective Alternative to Traditional Methods

Traditional methods of artifact replication, such as mold-making and casting, can be labor-intensive and expensive. 3D printing presents a cost-effective alternative, particularly when multiple copies are needed for interactive displays, educational programs, or traveling exhibits. Once a 3D model is created, printing additional copies becomes a matter of resources and time, significantly reducing overall costs.

Economic Impact Analysis

Traditional Casting

- High Setup Costs: $2,000-$10,000+ per mold

- Material Waste: Excess casting materials

- Labor Intensive: Skilled craftspeople required

- Time Consuming: Weeks for complex pieces

- Limited Modifications: New molds for changes

- Storage Requirements: Physical mold storage

3D Printing Approach

- Low Setup Costs: $200-$2,000 per digital model

- Material Efficiency: Only prints what's needed

- Automated Process: Minimal supervision required

- Rapid Production: Hours to days completion

- Easy Modifications: Digital file adjustments

- Digital Storage: No physical storage needs

Hybrid Strategy

- Best of Both: 3D printing for prototypes

- Volume Decisions: Casting for large quantities

- Material Matching: Traditional for specific materials

- Quality Requirements: Method per application

- Timeline Flexibility: Rapid vs. batch production

- Cost Optimization: Technology per project scale

Hands-On History: Enhancing Visitor Engagement

Nothing quite compares to the tactile experience of touching an object. Of course, this is generally prohibited in museum contexts where many items are fragile, rare, or both. 3D printing solves this problem by providing durable replicas that visitors can touch, hold, and even operate, depending on the nature of the artifact. This hands-on experience makes museum visits far more engaging and educational, especially for younger audiences and visitors with visual impairments.

3D printed fossil replicas enable hands-on exploration without risking damage to precious originals

Interactive Learning Applications

Enhanced Accessibility Features

Visual Impairments

- • Tactile exploration of shape and texture

- • Braille integration on replica bases

- • Audio descriptions triggered by touch

- • High-contrast surface treatments

Learning Differences

- • Kinesthetic learning through handling

- • Multi-sensory information processing

- • Reduced cognitive load through interaction

- • Self-paced exploration opportunities

Age-Appropriate Design

- • Child-safe materials and edges

- • Appropriate sizing for small hands

- • Durable construction for repeated use

- • Engaging textures and features

Educational Integration

- • Curriculum-aligned learning objectives

- • Teacher resource materials

- • Interactive demonstration capabilities

- • Assessment and evaluation tools

Case Study: Health in Space Exhibit at Canadian Aviation and Space Museum

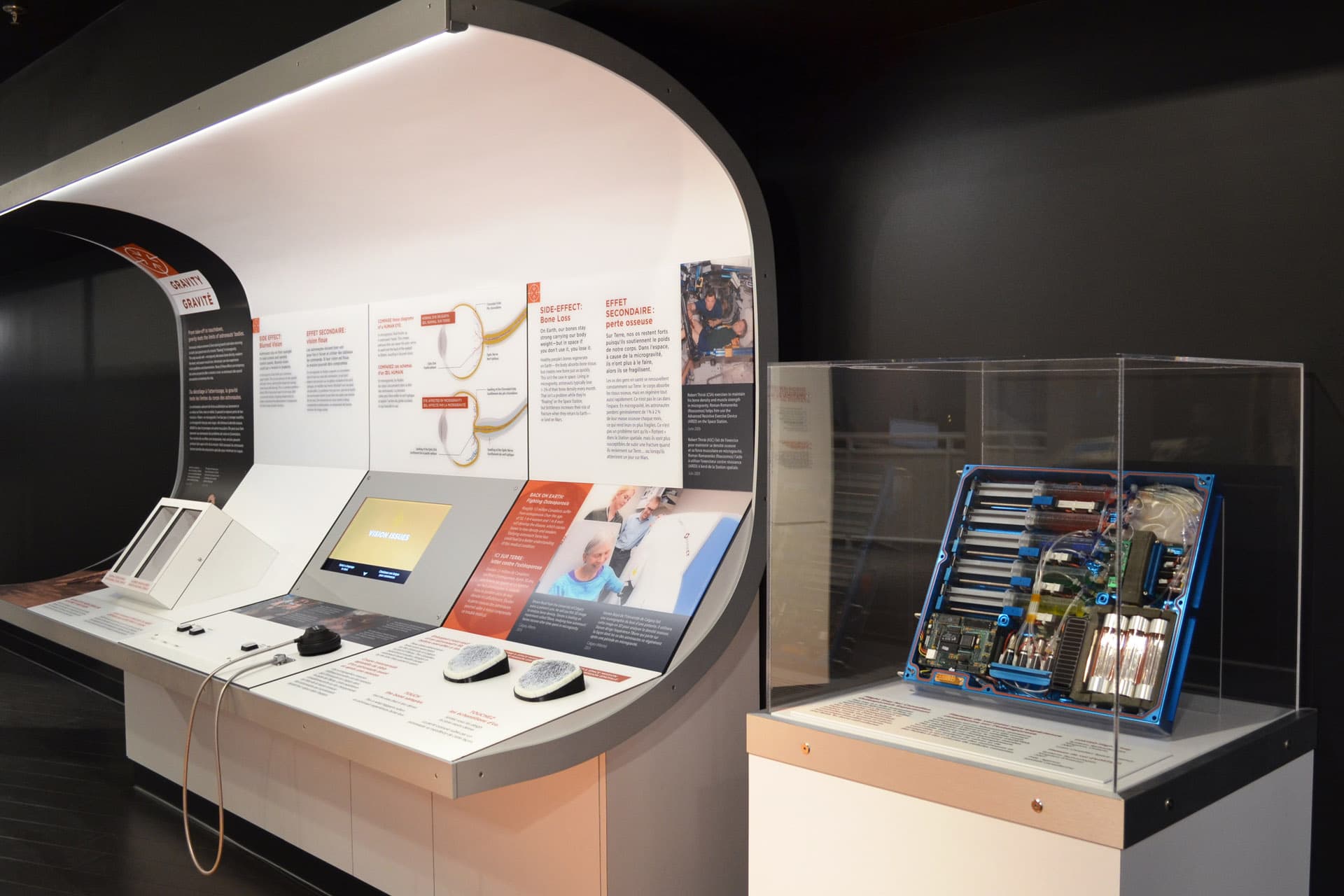

In 2018, W3 Design Group approached Forge Labs with scan data and a unique challenge: 3D printing bone scans showing the effects of low gravity on bone density for "Health in Space: Daring to Explore," a long-term exhibit at the Canadian Aviation and Space Museum. This project exemplifies how advanced 3D printing technologies can solve complex museum display challenges while enhancing visitor engagement.

Health in Space exhibit showcasing the effects of low gravity on human bone density through 3D printed models

Project Requirements and Challenges

The exhibit required tactile models that visitors could handle to understand how microgravity affects human bone density. However, the delicate features of actual bone structure would not survive frequent rough handling by museum attendees if printed as-is. The solution required innovative engineering and advanced multi-material 3D printing capabilities.

Technical Challenges

- Durability Requirements: Withstand repeated handling by thousands of visitors

- Tactile Authenticity: Maintain bone texture for educational value

- Structural Protection: Prevent fragile features from breaking

- Visual Clarity: Allow internal structure observation

- Scientific Accuracy: Preserve scan data integrity

- Installation Integration: Compatible with exhibit mounting systems

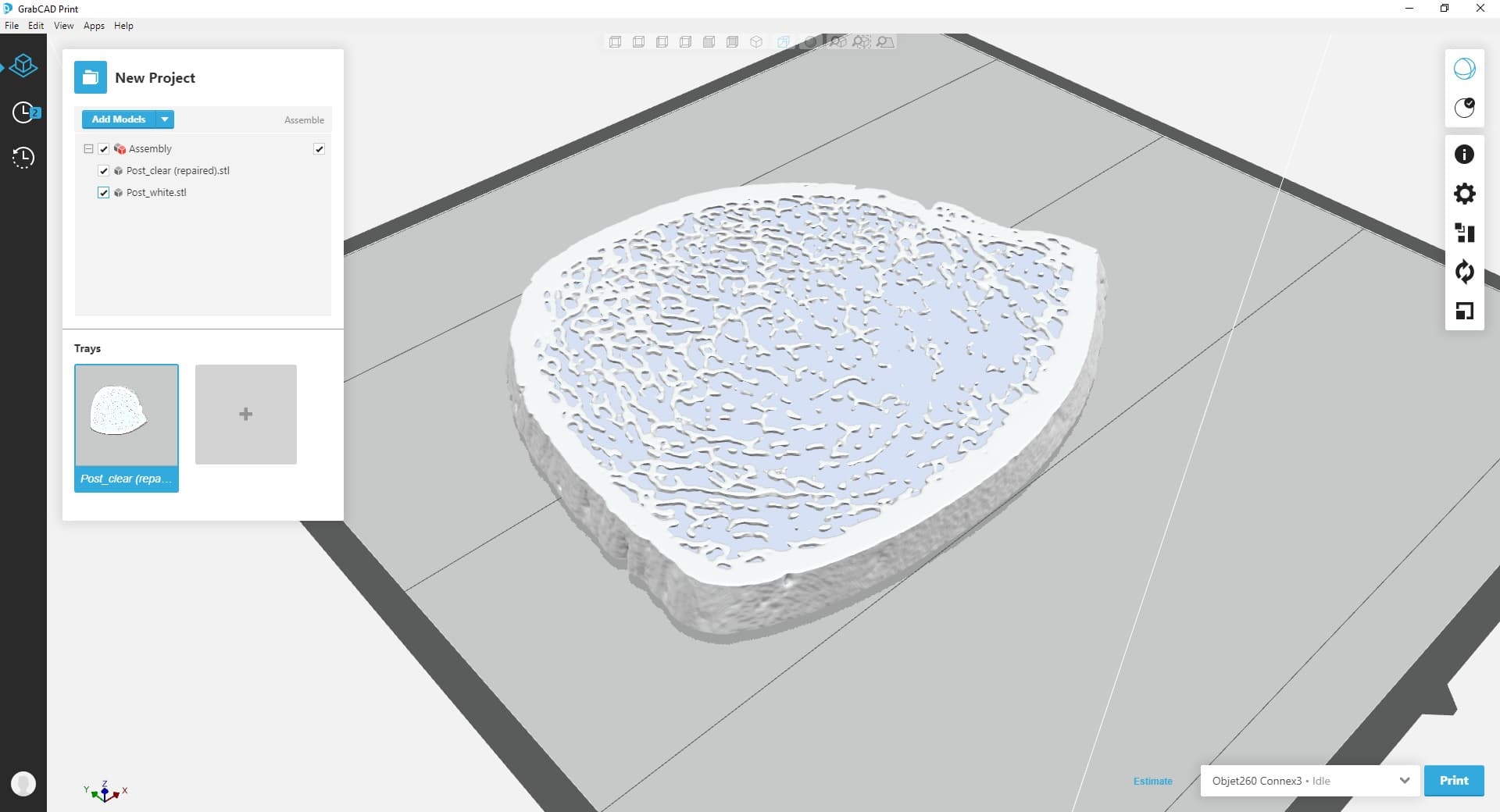

Innovative Multi-Material Solution

Our design team developed an innovative approach using advanced PolyJet multi-material 3D printing technology. The solution involved creating an inverse model of the supplied bone scan data, leaving only 1mm of 'bone' exposed on the upper surface—enough for attendees to feel the authentic texture, but not enough to create fragility issues.

Multi-material PolyJet printing combines Rigur bone material with VeroClear transparent matrix for protection

Technical Implementation

The two 3D models were printed simultaneously using our advanced PolyJet multi-material printing system, which allowed us to print both materials in a single build process:

- Rigur Material: Used for the bone structure, providing realistic texture and color

- VeroClear Material: Created the transparent 'marrow' matrix, protecting delicate features

- Seamless Integration: Both materials printed together without assembly requirements

- Precision Exposure: Exactly 1mm of bone surface accessible for tactile experience

PolyJet Connex3 multi-material 3D printer enables simultaneous printing of multiple materials

Structural Engineering and Installation

Beyond the display elements, the project required robust mounting solutions. The base was designed to closely mimic the upper bone shape and featured a 'keyed' connection system to ensure that parts would not detach even if struck horizontally. Fused Deposition Modeling (FDM) was selected for the base as a durable, cost-effective choice.

Display Component (PolyJet)

- Material: Rigur + VeroClear combination

- Function: Tactile exploration and visualization

- Features: 1mm exposed bone texture

- Protection: Transparent matrix support

- Accuracy: Preserves original scan data

Mounting Base (FDM)

- Material: Engineering-grade thermoplastic

- Function: Secure mounting and connection

- Features: Keyed anti-detachment system

- Hardware: Heat-sunk inserts per specifications

- Durability: Long-term exhibition use

Project Outcomes and Impact

The Health in Space exhibit demonstrates how thoughtful application of 3D printing technology can enhance museum experiences while solving complex technical challenges. The project achieved multiple objectives simultaneously: visitor engagement, educational effectiveness, artifact protection, and long-term durability.

Measurable Results

- Visitor Engagement: Increased interactive participation rates

- Educational Value: Enhanced understanding of space health effects

- Durability Success: Withstands daily visitor interaction

- Cost Effectiveness: Lower maintenance than traditional displays

- Accessibility Improvement: Hands-on learning for all abilities

- Scientific Accuracy: Preserved original scan data integrity

Advanced 3D Printing Technologies for Museums

Technology Selection for Museum Applications

Different 3D printing technologies offer unique advantages for museum applications. Understanding these capabilities enables museums to select the optimal approach for each specific exhibit requirement.

| Technology | Best Applications | Materials | Advantages |

|---|---|---|---|

| PolyJet | Multi-material displays, transparent elements | Rigur, VeroClear, rubber-like | Multi-material, high detail |

| SLA | High-detail replicas, jewelry, coins | Various resins, castable | Exceptional detail, smooth finish |

| SLS | Durable handling pieces, complex geometry | Nylon, glass-filled nylon | No supports, strong parts |

| FDM | Large displays, mounting hardware | ABS, PLA, engineering plastics | Large scale, cost-effective |

| DMLS | Metal artifacts, tool replicas | Stainless steel, aluminum, titanium | Metal properties, high strength |

Cultural Impact and Global Accessibility

Democratizing Cultural Heritage

3D printing technology is democratizing access to cultural heritage by enabling museums to share their collections globally. Digital files can be distributed to institutions worldwide, allowing local production of replicas without the costs and risks associated with shipping irreplaceable artifacts.

Global Collaboration

- Digital Exchange: Museums sharing 3D models

- Collaborative Exhibits: Joint international displays

- Research Networks: Scholarly cooperation

- Cultural Diplomacy: Heritage sharing programs

Educational Outreach

- School Programs: Classroom artifact access

- Distance Learning: Remote educational resources

- Community Engagement: Local cultural centers

- Inclusive Access: Underserved communities

Innovation Hub

- Technology Adoption: Early implementation

- Best Practices: Industry standards development

- Research Applications: Advanced analysis techniques

- Future Technologies: Emerging capabilities

Sustainable Museum Operations

Beyond immediate benefits, 3D printing contributes to more sustainable museum operations. Reduced need for climate-controlled display environments, lower shipping costs, and decreased risk of damage during transport all contribute to environmental sustainability while reducing operational expenses.

Future Trends and Emerging Applications

Technological Advancement Integration

As 3D printing technology continues advancing, museums are exploring integration with other emerging technologies to create even more immersive and educational experiences.

Emerging Technology Integration

Augmented Reality (AR)

- • Digital overlays on physical replicas

- • Historical context visualization

- • Interactive information systems

- • Multilingual interpretation support

IoT Integration

- • Smart exhibits with usage tracking

- • Predictive maintenance systems

- • Visitor behavior analytics

- • Environmental monitoring integration

Advanced Materials

- • Conductive filaments for interactive elements

- • Bio-based materials for sustainability

- • Color-changing materials for dynamic displays

- • Antimicrobial surfaces for health safety

AI and Machine Learning

- • Automated model optimization

- • Visitor preference adaptation

- • Predictive conservation analytics

- • Intelligent exhibit curation

Implementation Strategy for Museums

For museums considering 3D printing integration, a strategic approach ensures successful implementation and maximum benefit realization.

- Needs Assessment: Identify specific exhibit challenges and visitor engagement goals

- Technology Evaluation: Select appropriate 3D printing technologies for applications

- Pilot Programs: Start with small-scale implementations to prove concepts

- Staff Training: Develop internal capabilities or establish service partnerships

- Digital Infrastructure: Implement systems for 3D model management and archiving

- Quality Standards: Establish protocols for replica accuracy and durability

- Visitor Feedback: Measure engagement improvements and educational effectiveness

- Scalable Expansion: Gradually expand successful applications across collections

Ready to transform your museum exhibits? Our expert team specializes in museum applications of 3D printing technology. Contact us at sales@forgelabs.com to discuss your specific exhibit needs and explore how 3D printing can enhance visitor engagement while preserving your valuable collections.

Conclusion: A New Era for Cultural Institutions

3D printing has proven to be more than just a technological trend; it's a valuable tool that addresses many challenges facing modern museums. From enhancing visitor engagement and educational outreach to contributing to conservation efforts and academic research, 3D printing is fundamentally changing how we experience and preserve history.

The success of projects like the Health in Space exhibit demonstrates the technology's potential to create innovative solutions that simultaneously protect precious artifacts and enhance public access to cultural heritage. As museums continue to embrace digital transformation, 3D printing will play an increasingly important role in ensuring these institutions remain relevant, accessible, and sustainable for generations to come.

Key Transformation Areas

- Enhanced visitor engagement through tactile experiences

- Improved accessibility for diverse learning needs

- Cost-effective replication and exhibition strategies

- Advanced conservation and preservation methods

- Global cultural heritage sharing capabilities

- Sustainable operational practices

- Educational outreach expansion

- Future-ready technology integration

As we look toward the future, the convergence of 3D printing with other emerging technologies promises even more exciting possibilities for cultural institutions. Museums that embrace these innovations today will be best positioned to serve their communities and preserve human heritage for future generations.