DMLS 6061 enables complex aerospace structures with predictable properties matching decades of flight heritage. The material's proven performance reduces qualification requirements.

Key Applications

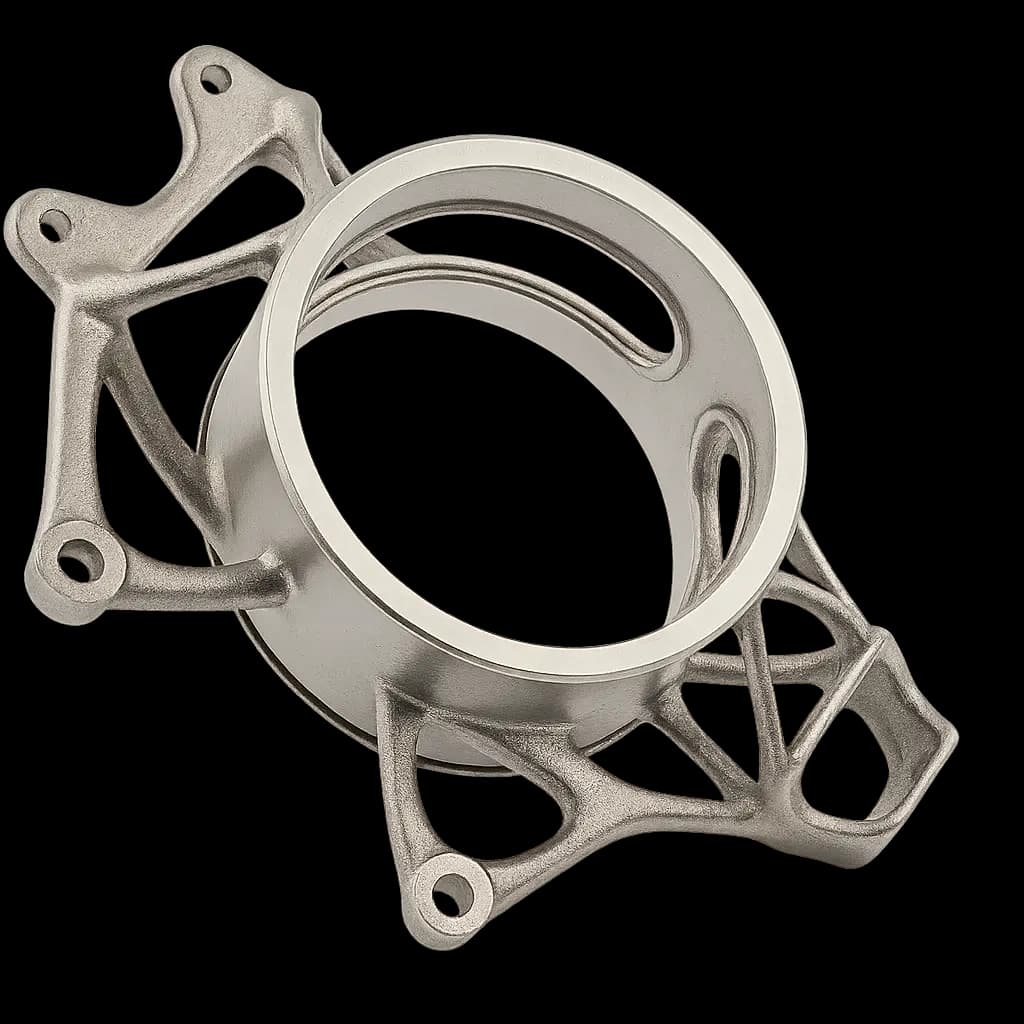

- Secondary structure brackets and fittings

- Avionics housings and mounts

- Ground support equipment

- Prototype primary structures

Performance Data

Achieves 275 MPa yield strength (T6) meeting aerospace design allowables with 35% weight reduction through topology optimization.