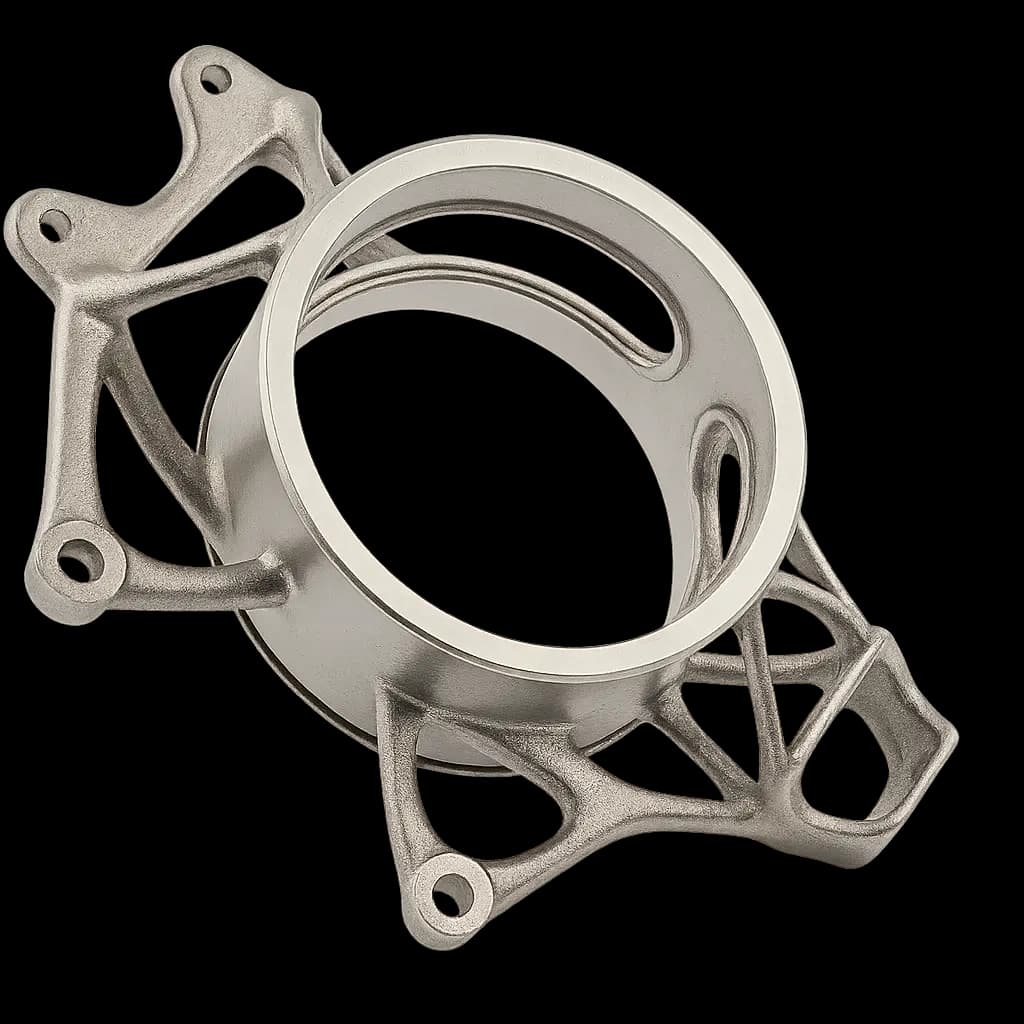

DMLS 316L enables complex surgical instruments with integrated features and ergonomic designs. The material's biocompatibility and sterilization resistance ensure patient safety.

Key Applications

- Laparoscopic surgical instruments

- Orthopedic surgical guides

- Dental instruments and tools

- Custom surgical retractors

Performance Data

Achieves Ra <0.4 μm with electropolishing, meeting FDA cleanability requirements while maintaining ASTM F138 compliance.