DMLS AlSi10Mg enables conformal cooling channels and complex heat exchanger geometries for aerospace thermal management. The process achieves thin walls down to 0.8mm for weight optimization.

Key Applications

- Heat exchangers with gyroid structures

- Electronic housing with integrated cooling

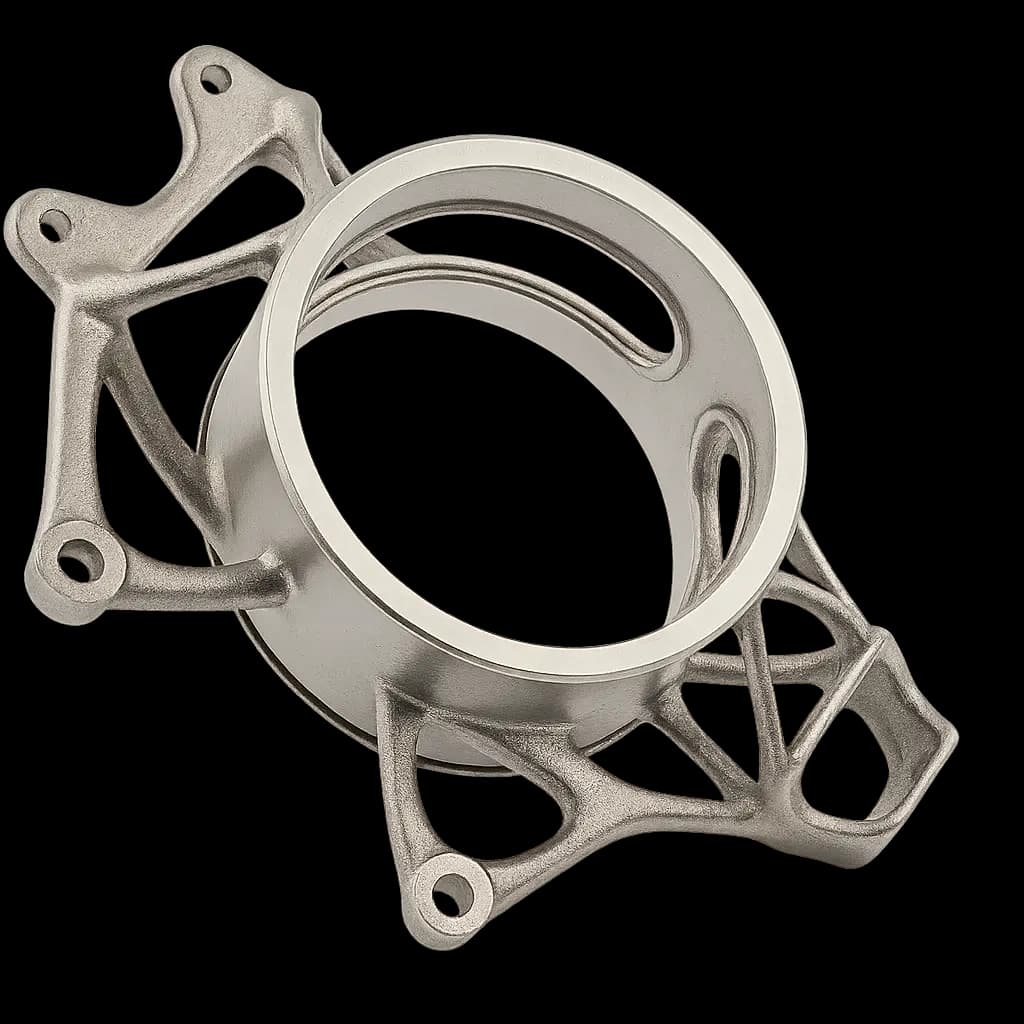

- Lightweight brackets and fixtures

- UAV structural components

Performance Data

Thermal conductivity 130 W/m·K with 40% weight reduction versus traditional heat exchangers, meeting aerospace cooling requirements.