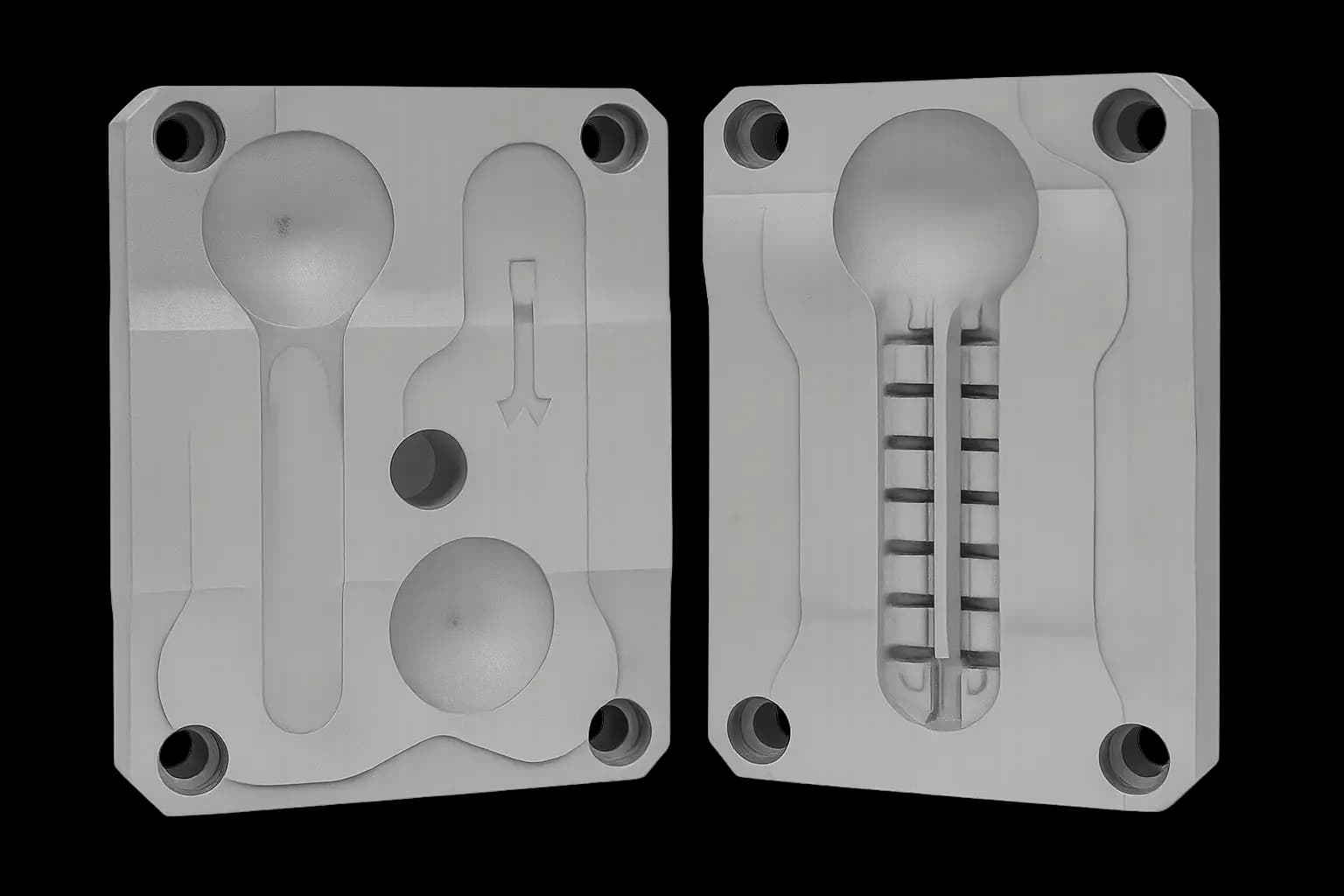

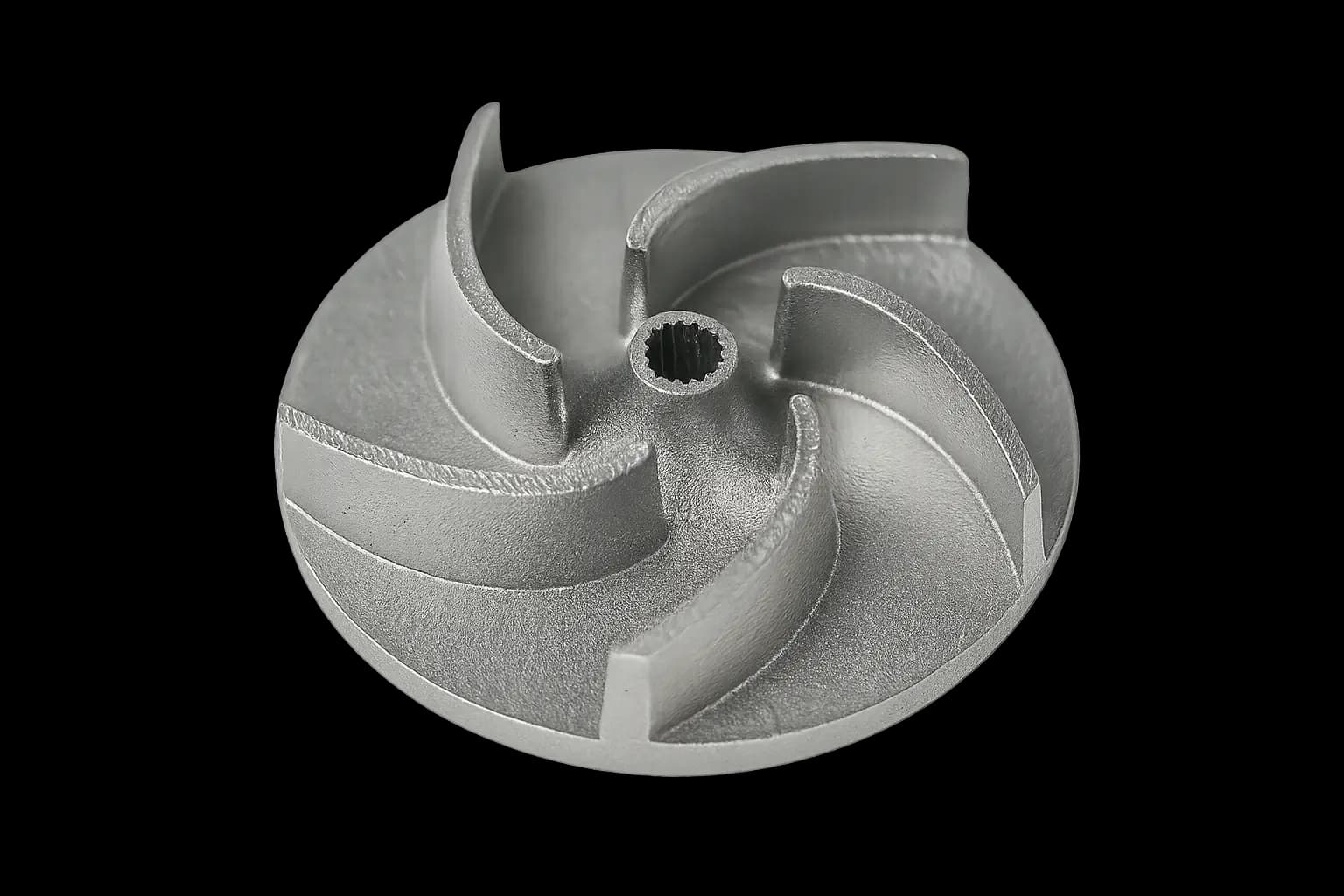

DMLS Maraging Steel revolutionizes injection molding and die casting with conformal cooling and extreme durability. The material survives millions of cycles with abrasive plastics.

Key Applications

- Injection mold inserts for glass-filled plastics

- Die casting dies for aluminum

- Hot stamping tools

- Extrusion dies

Performance Data

Achieves 54 HRC with conformal cooling enabling 40% cycle reduction while surviving 5M+ shots with 30% glass-filled plastics.