3D Printing Surface Finishes

Compare surface finishing options across all 3D printing technologies. From standard as-printed finishes to enhanced and premium post-processing treatments. Filter by technology, category, and application to find the perfect finish for your parts.

Interactive Surface Finish Database

Explore and compare surface finishing options across all 3D printing technologies. Filter by technology, finish category, or search for specific surface treatments.

Filter Surface Finishes

Standard Finish

Fine-textured Matte Surface

Selective Laser Sintered (SLS) parts naturally come in a fine-textured matte surface finish. Parts are depowdered through media blasting, resulting in a bright white color with a slightly grainy texture. The surface is durable, uniform, and functional, making it ideal for both mechanical and aesthetic applications. While intricate details are well-defined, the porous nature of SLS PA12 can lead to a slightly rough feel, which can be improved through post-processing techniques.

Deep Color Dye

Rich, Uniform Color Coverage

Deep color dying provides a rich, uniform color, improving the overall aesthetics. Suitable for both functional and visually appealing applications. The dye also enhances scratch resistance, making the parts more durable in handling and use. This process ensures consistent color uniformity across the entire part, even for complex geometries or intricate designs.

Vapour Finishing

Controlled Chemical Vapour Smoothing

Vapour finishing uses controlled chemical vapour to smooth the surface texture of SLS parts, reducing the characteristic powder grain while maintaining dimensional accuracy. This process creates a more refined surface feel and appearance, making it ideal for parts requiring improved aesthetics or user interaction. The result is a smoother touch feel while preserving the structural integrity and detail definition of the original part.

Performance Paint

Automotive-Grade Coating

Painting offers a highly durable, automotive-grade coating that enhances the aesthetics and durability of 3D-printed parts. Each part is hand-finished to ensure smooth surfaces and a premium quality appearance. Using professional-grade coating equipment, this process allows for precise application and exceptional adhesion. Custom color matching is available, making it ideal for applications that require specific branding or visual impact.

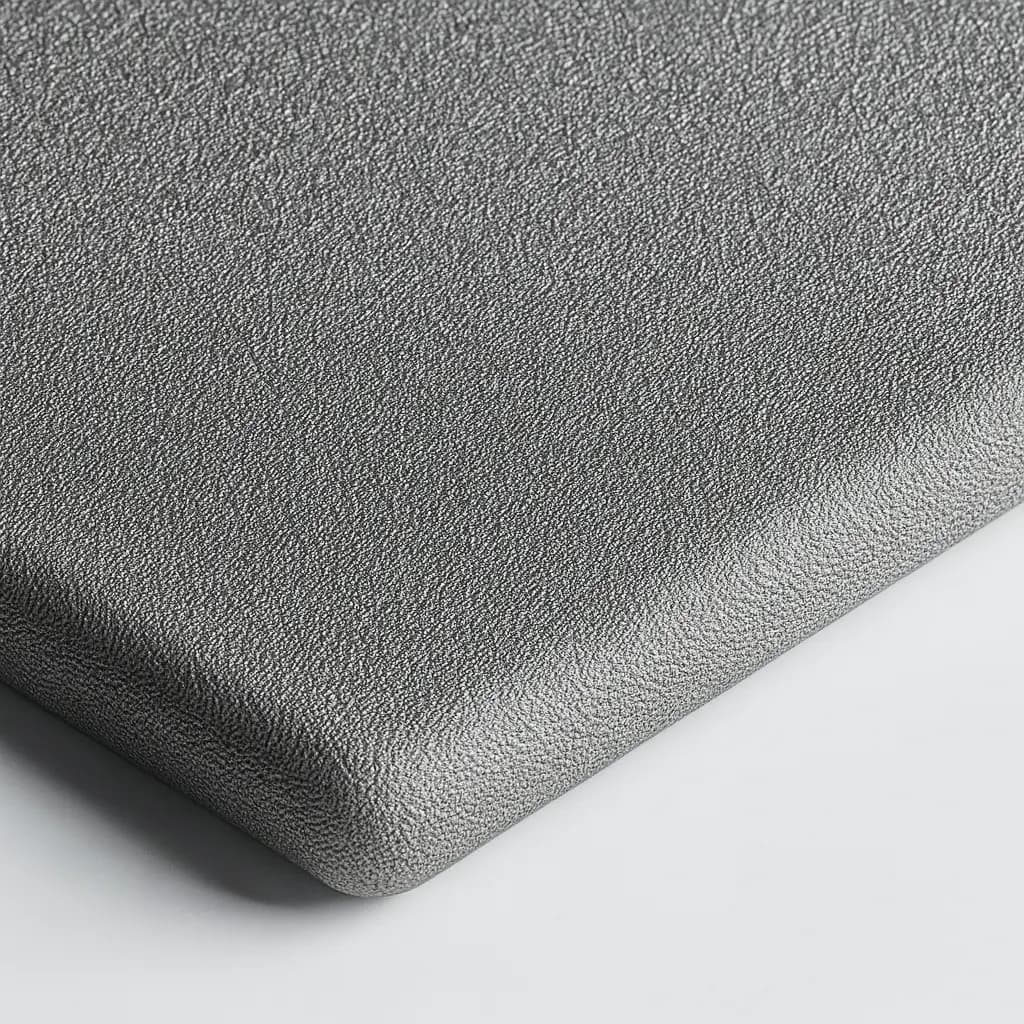

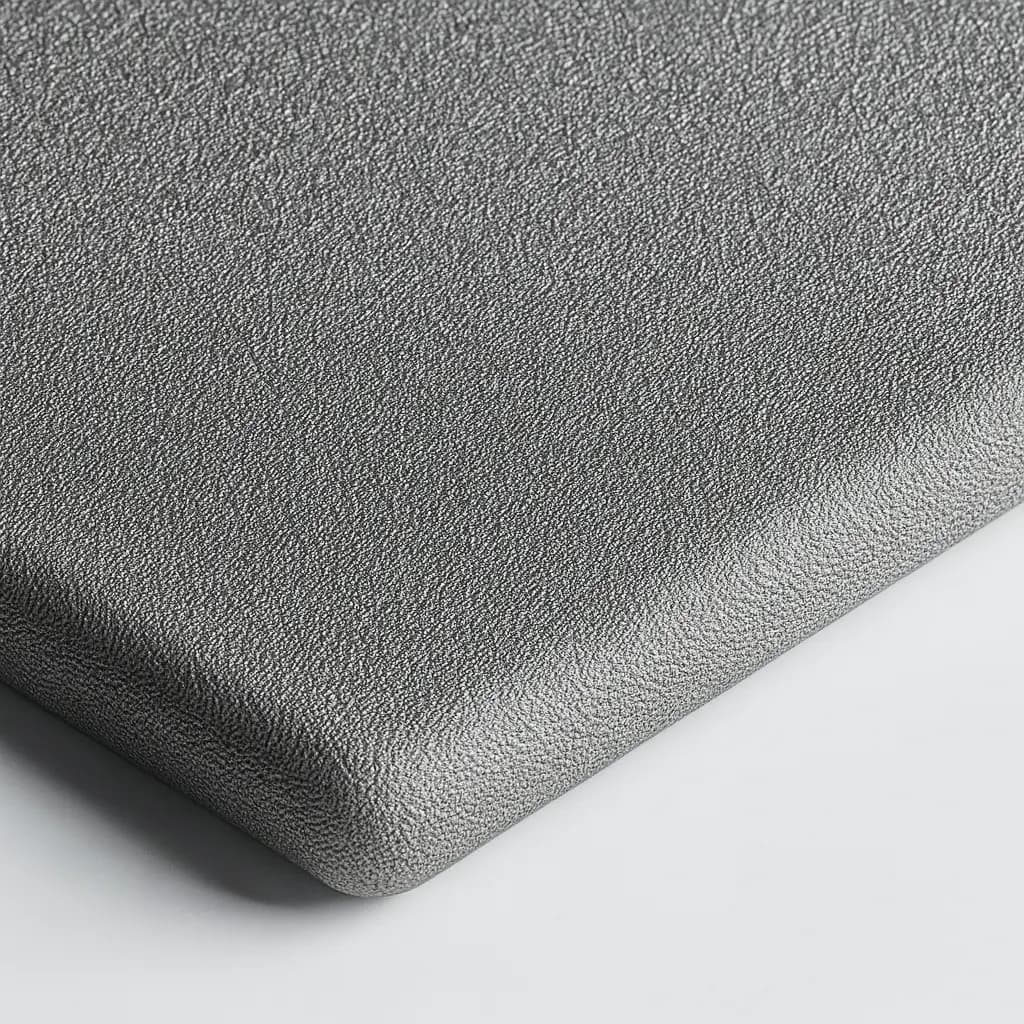

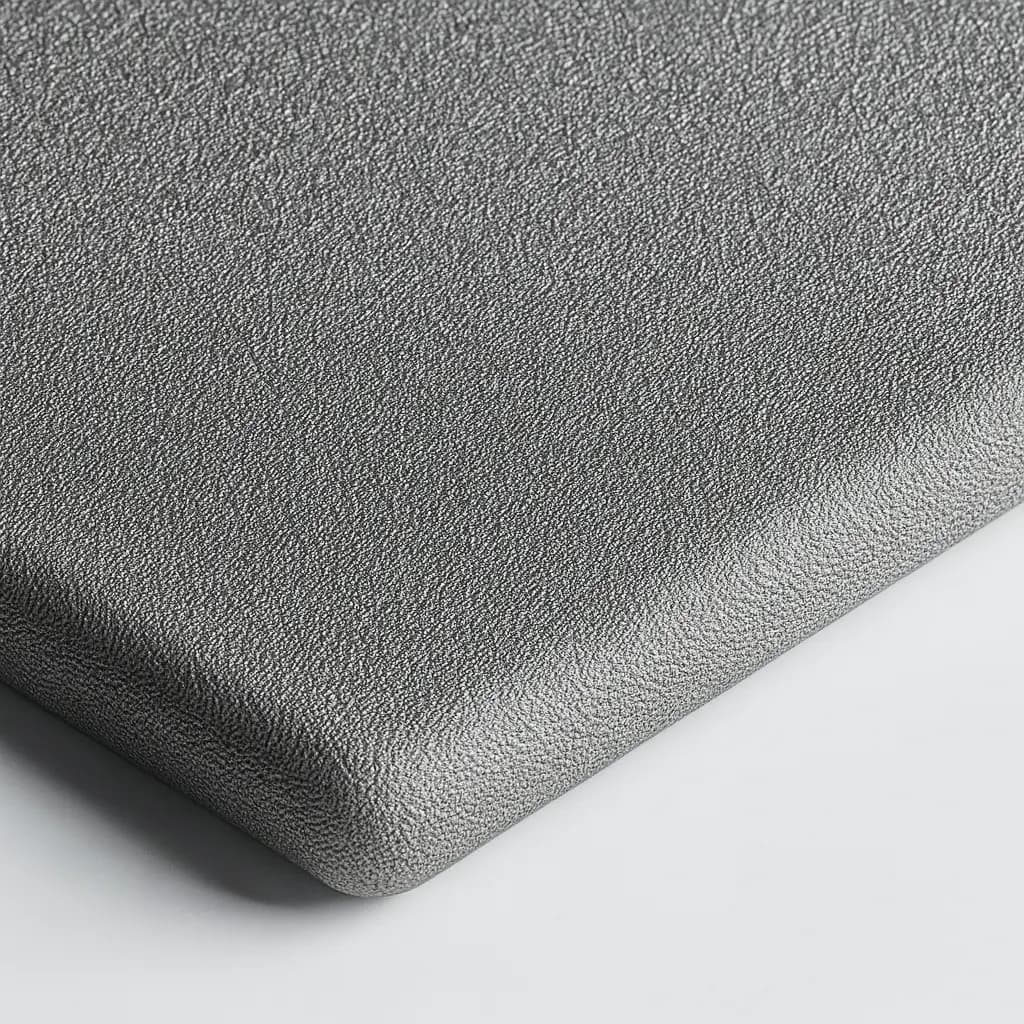

Standard Finish

Natural Grey

MJF parts are delivered with a standard bead-blasted finish in natural grey. This process removes excess powder and slightly smooths the surface while maintaining the material's natural matte texture.

Deep Color Dye

Dyed Black

Specialized dye bath creates deep, uniform black color that chemically bonds with the nylon material. Unlike painted finishes, the dye fully penetrates the surface and won't chip or wear off over time.

Vapor Smoothing

Enhanced Finish

Advanced chemical smoothing technique that enhances surface quality by slightly melting and redistributing the surface material, eliminating grainy texture and sealing porous areas.

Performance Paint

Custom Finish

Automotive-grade coating that enhances aesthetics and durability. Hand-finished for smooth surfaces with professional-grade equipment. Custom color matching available for precise branding needs.

Standard Finish

Visible Layer-by-Layer Texture

FDM 3D printed parts have a visible layer-by-layer texture with slight ridges and striations, resulting in a rougher surface finish compared to other 3D printing technologies like SLS or SLA. Soluble supports are dissolved in an ultrasonic cleaning tank, while physical supports on high-temperature materials are removed by hand if required.

Vapor Smoothing

Chemically Smoothed Surface

Vapor smoothing dissolves the outer layer, causing it to smooth out and blend, reducing layer lines and enhancing the part's appearance. This process creates a glossy, sealed surface with improved strength, reduced porosity, and increased chemical resistance, making it ideal for functional and aesthetic applications.

Performance Paint

Automotive-Grade Coating

Painting offers a highly durable, automotive-grade coating that enhances the aesthetics and durability of 3D-printed parts. Each part is hand-finished to ensure smooth surfaces and a premium quality appearance. Using professional-grade coating equipment, this process allows for precise application and exceptional adhesion. Custom color matching is available, making it ideal for applications that require specific branding or visual impact.

Standard Finish

As-Printed Surface

FFF parts have visible layer-by-layer texture with support removal marks. Suitable for concept validation and non-customer-facing applications.

Learn more about FFF

Standard Finish

Natural Grey

Support structures are carefully removed, and parts undergo shot peening to create a uniform, matte surface and help relieve residual stresses. Critical features may receive light machining for tighter tolerances.

Machining & Polishing

Enhanced Finish

Precision machining and polishing processes enhance surface quality, achieving tighter tolerances and smoother finishes for critical applications.

Anodizing

Anodized Finish

For aluminum parts, anodizing forms a protective oxide layer, significantly enhancing corrosion resistance and hardness while improving appearance.

Performance Paint

Premium Finish

Automotive-grade coating that enhances aesthetics and durability. Each part is hand-finished with professional-grade equipment for exceptional adhesion and custom color matching.

Natural Finish

As-Printed Surface Quality

PolyJet Matrix parts feature exceptional surface quality straight from the printer with minimal layer lines and smooth finish. The natural finish maintains fine detail resolution while providing a slightly off-white color with matte texture. This finish is ideal for functional testing and design validation without additional processing.

Performance Paint

Automotive-Grade Coating

Professional automotive-grade painting provides highly durable coating with custom color matching capabilities. Parts are hand-finished to high quality standards using professional coating equipment. Available in matte to semi-gloss finishes with precise color matching for branding requirements.

As-Machined

Ra 1.6 - 3.2 Micrometers

Parts deburred and cleaned straight from the machine with visible tool marks. Ideal for functional components and internal features where cosmetic appearance is not critical.

Precision Milled

Ra 0.4 - 0.8 Micrometers

Fine tooling and optimized stepovers produce near-polished surfaces on sealing, optical, or cosmetic faces without secondary finishing.

Post-Processed

Custom Finishing and Coatings

Includes bead blasting, anodizing, chem film, passivation, electropolishing, painting, and part marking tailored to your specification.

Need Help Choosing the Right Surface Finish?

Our surface finishing experts can help you select the optimal finish for your specific application requirements, appearance needs, and performance criteria.