A decade ago, 3D printing dominated tech headlines with promises of revolutionary change. Today, while the consumer hype has subsided, additive manufacturing has quietly transformed into an industrial powerhouse driving innovation across aerospace, automotive, marine, healthcare, and entertainment sectors.

The journey from consumer novelty to industrial necessity reveals the true maturation of 3D printing technology. Far from disappearing, additive manufacturing has found its optimal applications, becoming essential infrastructure for rapid prototyping, end-use production, and solving complex manufacturing challenges across North America's most demanding industries.

What You'll Learn

- • The rise and reality check of 3D printing hype

- • Why consumer predictions didn't materialize

- • Industrial applications driving today's growth

- • Real-world success stories across key industries

- • The future of additive manufacturing

The Rise and Hype of 3D Printing

The 3D printing revolution began in earnest during the 1980s with Chuck Hull's invention of stereolithography, but it wasn't until the early 2010s that the technology captured global imagination. The convergence of expiring patents, open-source initiatives like RepRap, and compelling media narratives created unprecedented excitement about manufacturing's future.

The Promise vs. Reality

What Was Promised (2010-2015)

- • 3D printer in every home

- • Download-and-print consumer goods

- • Decentralized manufacturing

- • Elimination of traditional supply chains

- • Mass customization for everyone

What Actually Happened

- • Industrial adoption accelerated rapidly

- • Specialized applications found their niches

- • Professional manufacturing transformed

- • Supply chains evolved, not disappeared

- • Enterprise-level customization emerged

The peak excitement centered around democratization—visions of consumers downloading designs and printing household items in their living rooms. Media outlets showcased everything from 3D-printed toys to rocket components, creating expectations that every industry would be immediately transformed by desktop manufacturing.

Why Consumer Predictions Didn't Materialize

While 3D printing revolutionized prototyping and specialized manufacturing, the broader consumer predictions encountered several fundamental challenges that the early hype underestimated:

Economic Realities

- • High-quality printers remained expensive ($2,000-$10,000+)

- • Material costs exceeded injection molding for volume production

- • Maintenance and operational complexity

- • Time-per-part economics favored traditional methods

Technical Limitations

- • Limited material properties vs. injection molding

- • Surface finish requirements for consumer goods

- • Support removal and post-processing labor

- • Print failure rates and quality consistency

User Experience Barriers

- • 3D design skills requirement

- • Complex software ecosystems

- • Printer calibration and troubleshooting

- • Quality control and safety considerations

Industrial 3D Printing Today

While consumer applications plateaued, industrial adoption exploded. The technology found its optimal applications where its unique capabilities—design freedom, rapid iteration, and customization—provide clear competitive advantages over traditional manufacturing methods.

Industry growth statistics demonstrate the rapid expansion of 3D printing in professional applications

Industrial Growth Metrics

- • $18.3B global additive manufacturing market (2024)

- • 23.5% CAGR projected through 2030

- • 75% of aerospace companies use 3D printing

- • 50% of automotive OEMs have production applications

- • $2.4B North American market share

- • 60% growth in metal 3D printing (2020-2024)

- • 40% of medical devices use additive components

- • 30% reduction in prototyping timelines industry-wide

Real-World Applications Across Industries

At Forge Labs, we've witnessed firsthand how 3D printing has become mission-critical infrastructure across North America's most demanding industries. Here's how additive manufacturing is transforming key sectors:

Aerospace & Defense

The aerospace industry has embraced 3D printing for both prototyping and flight-qualified end-use parts. DMLS technology enables complex internal geometries impossible with traditional machining, while achieving the stringent material properties required for aviation applications.

- • Titanium engine components with integrated cooling channels

- • Lightweight brackets with topology-optimized designs

- • Rapid prototyping for R&D and testing programs

- • Low-volume production for specialty aircraft

Advanced DMLS components demonstrate the precision possible in aerospace applications

Automotive Manufacturing

Automotive tooling and components manufactured using industrial 3D printing

Automotive manufacturers leverage 3D printing for rapid prototyping, tooling, and increasingly for end-use production parts. The technology enables faster development cycles and cost-effective customization for electric vehicles and luxury segments.

- • Jigs and fixtures for assembly line optimization

- • Prototype components for testing and validation

- • End-use parts for low-volume specialty vehicles

- • Tooling inserts for injection molding optimization

Marine & Subsea Engineering

Marine applications demand components that withstand extreme environments while maintaining precise performance. 3D printing enables complex hydrodynamic designs and rapid deployment of specialized equipment for subsea operations.

- • AUV components with integrated electronics housings

- • Hydrodynamic fins with optimized flow characteristics

- • Corrosion-resistant housings for harsh environments

- • Custom sensor mounts for scientific equipment

Precision-engineered submarine fin demonstrating marine 3D printing capabilities

Architectural Design & Construction

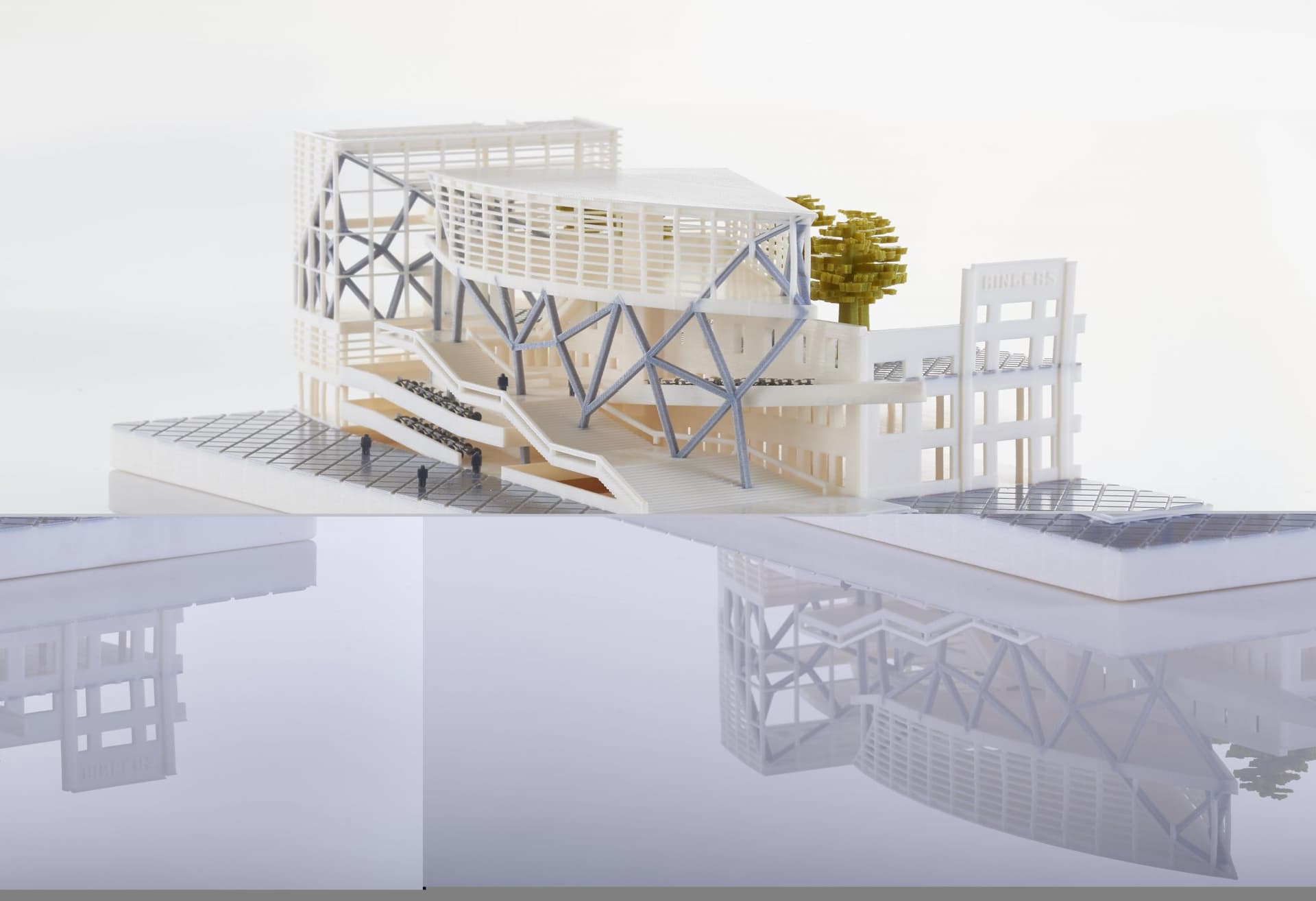

Detailed architectural scale model showcasing complex geometric features

Architectural firms rely on 3D printing for detailed scale models, design validation, and client presentations. The technology enables rapid iteration of complex designs and accurate representation of architectural details.

- • Scale models with intricate architectural details

- • Design prototypes for client presentations

- • Construction components for specialized installations

- • Massing studies for urban planning projects

Film & Entertainment

The entertainment industry has embraced 3D printing for creating intricate props, costumes, and set pieces. The technology enables rapid prototyping of creative designs and cost-effective production of detailed replicas.

- • Custom props with intricate geometric details

- • Costume components for sci-fi and fantasy productions

- • Set decoration elements and architectural details

- • Replica weapons and hero props for close-up shots

Professional film props demonstrating the detail and quality possible with 3D printing

3D Printing in Everyday Life

While industrial applications dominate, 3D printing has quietly revolutionized several consumer-facing sectors, particularly in healthcare and personalized products:

Medical & Dental Applications

- • Custom hearing aids: 95% of hearing aids worldwide are 3D printed

- • Dental aligners: Invisalign produces 500,000+ aligners daily

- • Prosthetics: Custom-fit limbs and orthotics

- • Surgical guides: Patient-specific surgical planning tools

- • Implants: Titanium implants with bone-integration surfaces

Consumer Personalization

- • Eyewear: Custom-fit frames based on facial scans

- • Footwear: Personalized insoles and specialty athletic shoes

- • Jewelry: Complex geometric designs impossible to cast

- • Electronics: Custom cases and specialized housings

- • Automotive: Personalized interior components for luxury vehicles

The Future of Additive Manufacturing

As 3D printing technology continues evolving, several trends are shaping its future applications and market position:

Material Innovation

- • High-performance polymers (PEEK, PEI)

- • Advanced metal alloys (superalloys, refractory metals)

- • Composite materials with embedded electronics

- • Bio-compatible and biodegradable materials

Process Advancement

- • Larger build volumes for industrial components

- • Faster print speeds with equivalent quality

- • Multi-material printing in single builds

- • In-process quality monitoring and control

Industry 4.0 Integration

- • AI-optimized design and topology optimization

- • Automated post-processing and quality control

- • Distributed manufacturing networks

- • Real-time supply chain adaptation

Market Projections & Trends

Growth Drivers

- • Aerospace industry expansion and space commercialization

- • Electric vehicle adoption requiring lightweight components

- • Personalized medicine and aging population healthcare needs

- • Supply chain resilience and localized manufacturing

Emerging Applications

- • Construction and large-scale infrastructure printing

- • Food production and personalized nutrition

- • Electronics manufacturing with embedded components

- • Sustainable manufacturing with recycled materials

Forge Labs: Leading Industrial Innovation

At Forge Labs, we've positioned ourselves at the forefront of this industrial transformation. Our comprehensive additive manufacturing capabilities span multiple technologies and materials, serving clients across North America's most demanding industries.

Our Industrial Capabilities

Technologies

- • DMLS (Direct Metal Laser Sintering)

- • SLS (Selective Laser Sintering)

- • FDM (Fused Deposition Modeling)

- • SLA (Stereolithography)

- • MJF (Multi Jet Fusion)

- • PolyJet Matrix

Materials

- • Titanium Ti-6Al-4V

- • Aluminum AlSi10Mg

- • Stainless Steel 316L & 17-4 PH

- • High-performance polymers

- • Engineering thermoplastics

- • Biocompatible resins

Services

- • Rapid prototyping (24-48 hour turnaround)

- • End-use production parts

- • Design optimization consulting

- • Post-processing and finishing

- • Quality certification support

- • Supply chain integration

Conclusion: The Real Revolution

The question "What happened to 3D printing?" reveals a fundamental misunderstanding of technological adoption cycles. Rather than disappearing, 3D printing underwent natural market evolution—moving from consumer hype to industrial necessity, from broad promises to specific solutions, from novelty to infrastructure.

Today's additive manufacturing landscape is more robust, specialized, and impactful than the early visionaries imagined. While we may not have 3D printers in every home, we have industrial systems producing flight-qualified aircraft components, life-saving medical devices, and cutting-edge research tools that were impossible to manufacture just a decade ago.

The Real Impact

3D printing didn't revolutionize manufacturing by replacing it—it revolutionized manufacturing by enhancing it. The technology found its optimal applications where its unique capabilities provide clear competitive advantages:

- • Complex geometries impossible with traditional manufacturing

- • Rapid prototyping that accelerates innovation cycles

- • Mass customization for high-value applications

- • Low-volume production with economic viability

- • Supply chain resilience through distributed manufacturing

Whether you're developing next-generation aerospace components, creating architectural masterpieces, or bringing film visions to life, discover how Forge Labs can help you harness the true power of additive manufacturing. The revolution isn't coming—it's here, it's industrial, and it's transforming how we design, prototype, and manufacture across every sector of the modern economy.

Ready to Experience Industrial 3D Printing?

From rapid prototyping to end-use production, Forge Labs delivers the advanced manufacturing solutions that drive innovation across North America's leading industries.