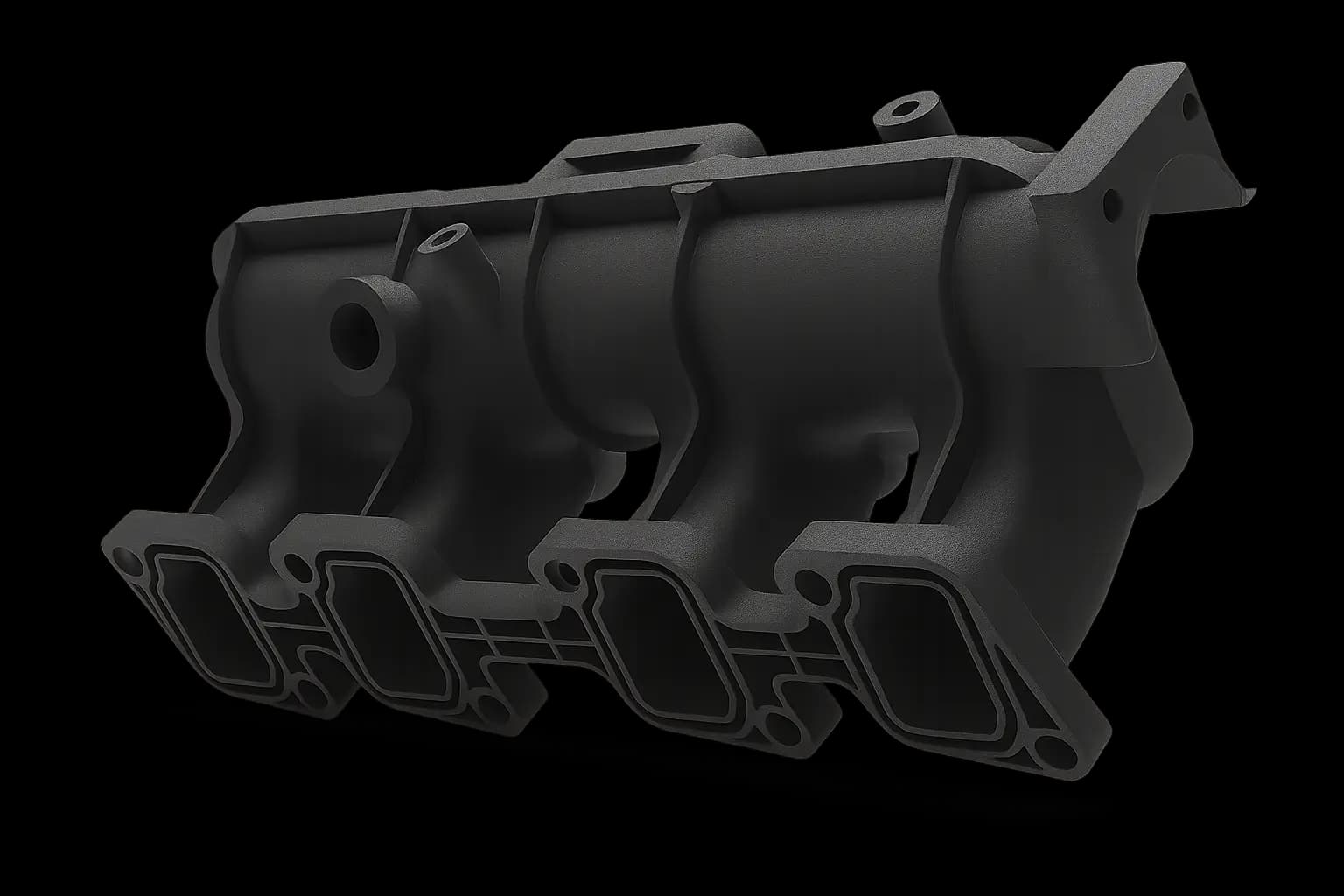

PEEK (CNC Grade) keeps Aerospace programs moving: Insulators, manifolds, and structural parts in thermal extremes.

Mechanical: Ultimate Tensile Strength: 100 MPa. Steam-managed DFM validates each CNC Machining build package for High Temperature Components.