Antero 800NA meets the stringent requirements for aerospace applications, from commercial aircraft interiors to satellite components. The material's low outgassing and radiation resistance enable space applications.

Key Applications

- Aircraft interior brackets and panels

- Satellite structural components

- Electrical connectors and housings

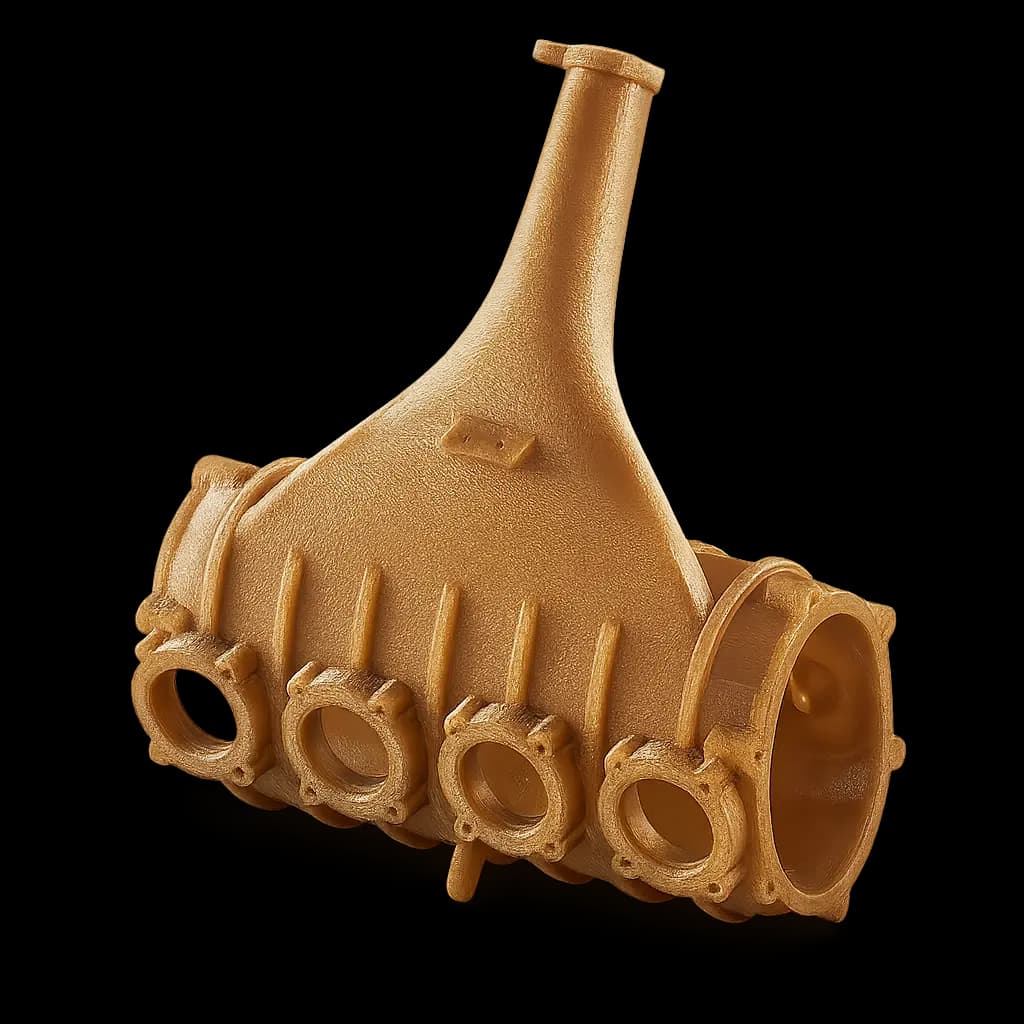

- Environmental control system parts

Performance Data

Meets FAR 25.853 with <1% TML and <0.01% CVCM per ASTM E595, qualified for unlimited use in aircraft interiors and space.